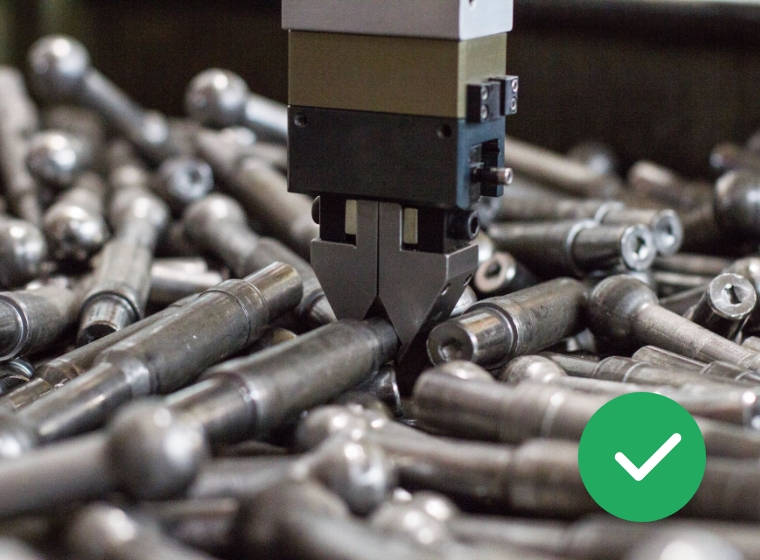

The powerful controller enables comparatively faster product and gripper changes than conventional systems. Changeover times are thus minimized. Cycle times as fast as 6 seconds are possible, depending on the products.

High system availability is due to the collision-free movement of the robot and the gripped products. The user-friendly interface allows the end user to create new parts without extensive programming knowledge.

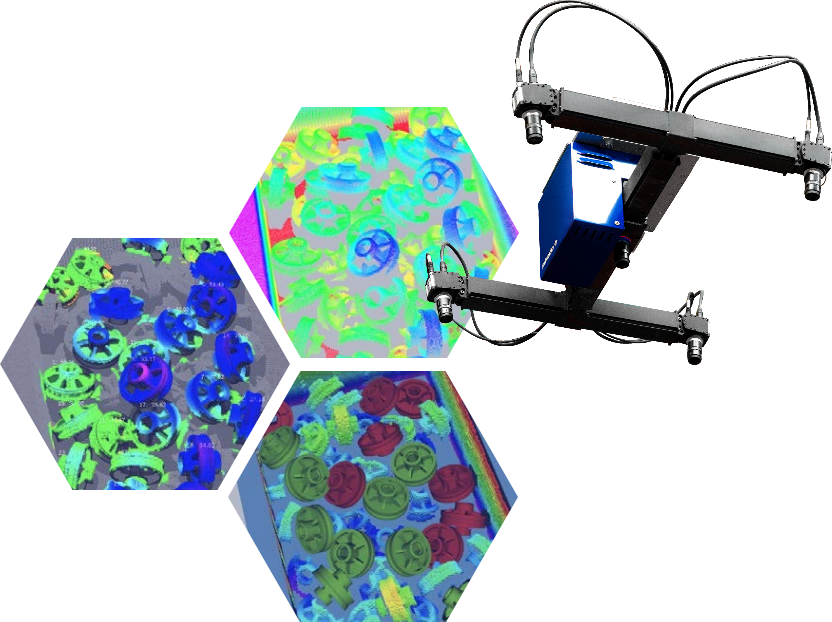

The unit and the vision system (camera, resolution, and lens) are specifically tailored to each customer's needs. The integrated product management is designed with a large volume in mind. For maximum flexibility.

The perfect bin-picking cell for speedy separation

Address the shortage of skilled workers

with an automation solution from Rotte: CAMGripX-1200

No problem! Our CAMGripX-1200

ensures efficient separation.

Experience CAMGripX-1200

in action – Visit us on site.

The benefits of the CAMGripX-1200 give you a competitive edge.

Benefit from our experts’ expertise, and convince yourself of the many possibilities offered by our technology.

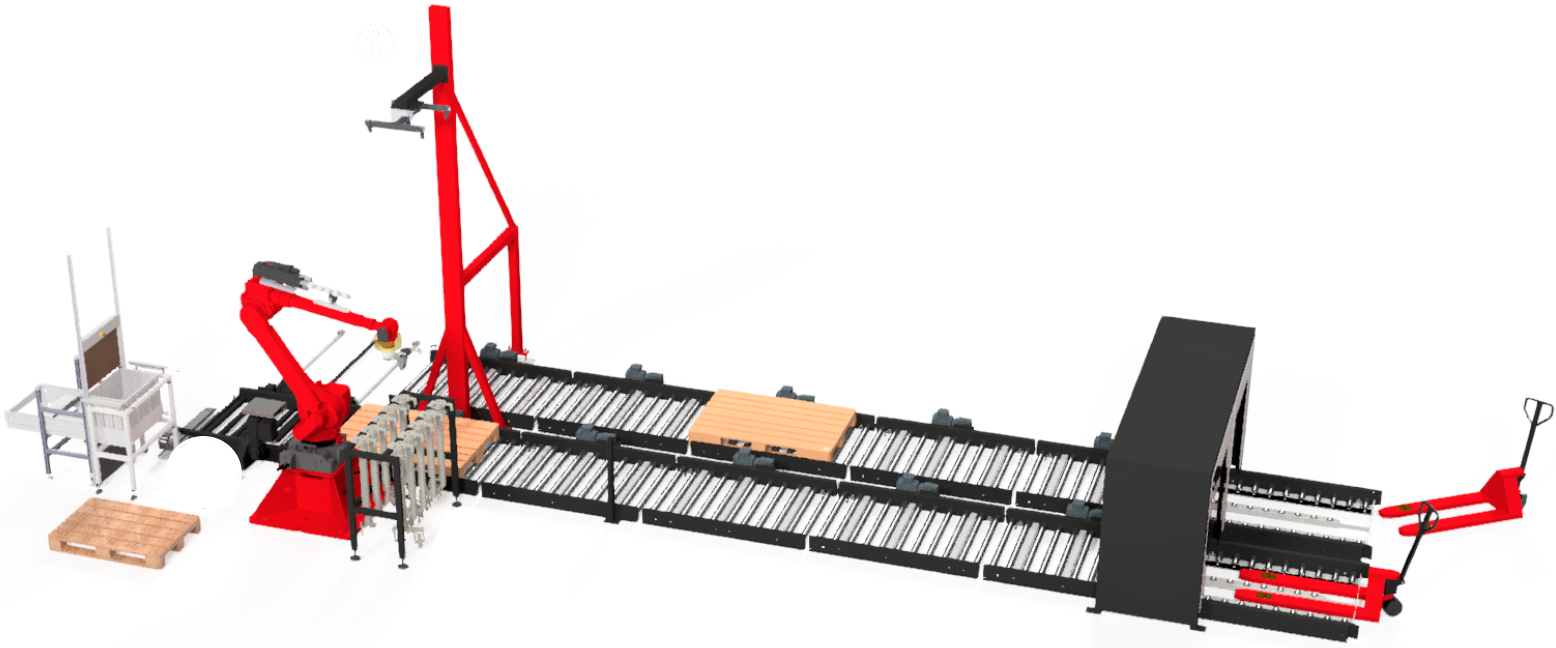

Rotte-Service:

By rebuilding or expanding, you have the opportunity to quickly and cost-effectively adapt your machines to the latest requirements and trends - and of course always maintain safety and quality in your production operation.

Every bin picking application is unique

The feasibility depends on the provision, presentation form, product and further processing.

Strengthen your competitive position, and save time and costs

| CAMGripX-1200 | With its high precision and fast changeover times, this system is the perfect choice for companies that want to make their production more efficient and increase their flexibility. |