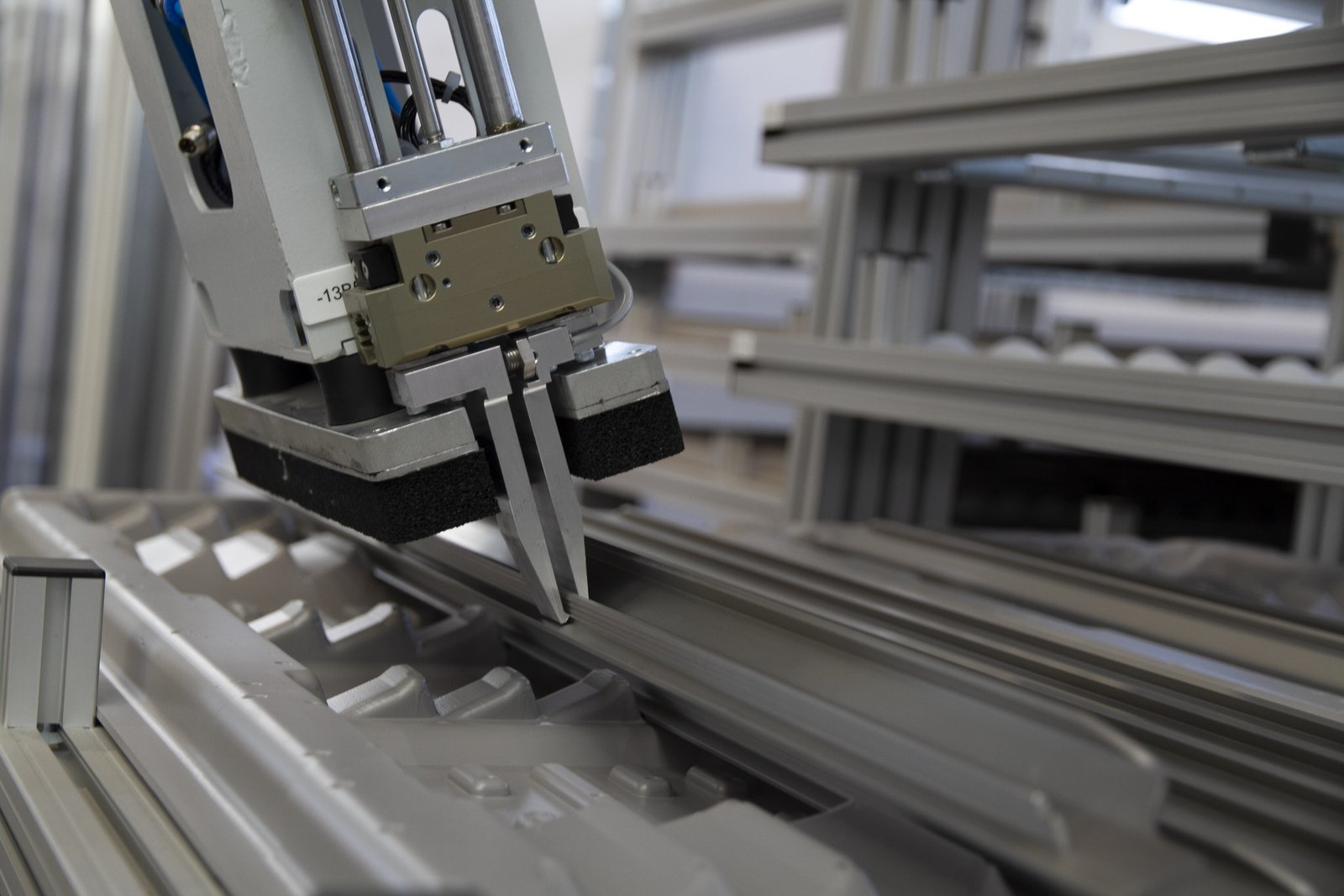

- Removal of handle strips from the push rack

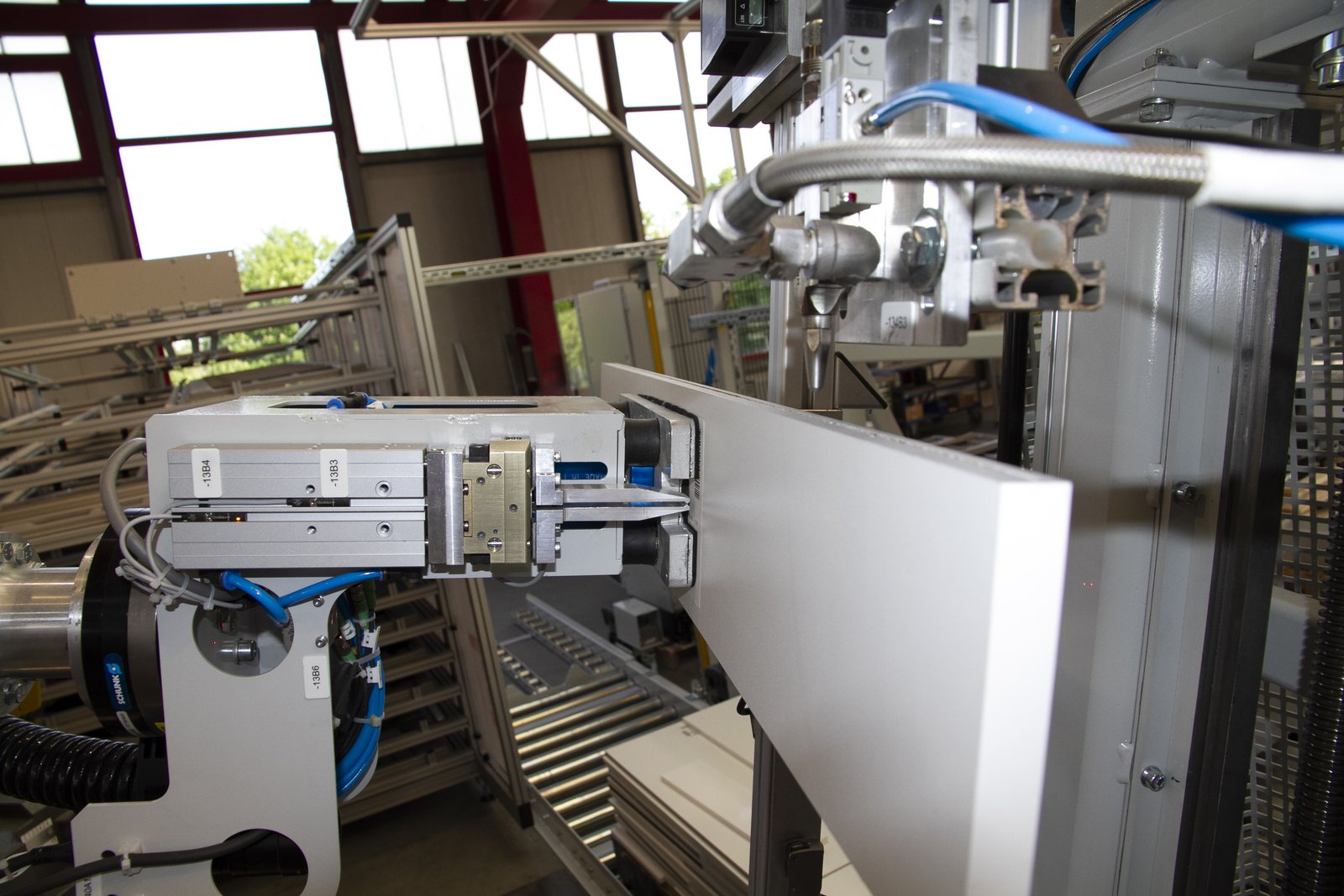

- Conveyance of the fronts to the pallet

- Pallets with undefined content

- Exact positioning on the pallet not required

- Exchange of data with the master computer

- Orientation of grooves towards gluing

- Automatic gluing of the fronts

- Joining the handle strip to the front

- Storing in shelving rack for manual removal

Description:

The robot cell is used to automatically attach handle strips to fronts of batch size 1.

Material for the fronts is fed on pallets in “randomly” packed stacks. A scanner or bar code system is able to detect the positions, and the dimensions are checked by a master controller system while the specifications for the handle strip type are also transferred. The handle strips are delivered in trays on a push rack. The robot removes the appropriate handle strip delivered to it in the rack and puts the strip into the assembly device. After a front has been gripped, it is oriented properly and glued in an automatic glue dosing process. Then the front or the base is also inserted into the assembly device where the handle strip is attached to the relevant component. The assembled fronts are then placed into a split magazine. While one magazine is loaded with empty trays, an employee can empty the other magazine containing the filled trays. This automated process boost your production quality because there will be no pressure or hammer marks on the handle strips, you will achieve a uniform gluing process and the handle bars are introduced to the fronts and bottoms in a center position. Depending on the design of the puffer places within the feeding and storage system, the system can operate in an independent and self-sufficient manner.

![[Translate to English:] [Translate to English:] Roboterzelle zur automatisierten Montage von Griffleisten](/fileadmin/_processed_/7/5/csm_Griffleistenmontage__3__fce4176b25.jpg)