- Verification of the correct assignment of the barcode to the workpiece

- Situation-dependent intermediate buffering of parts

- Strategic material flow planning for most efficient plant utilization

- Automatic stacking pattern generation

- Driverless transport of empty and full plates

Description:

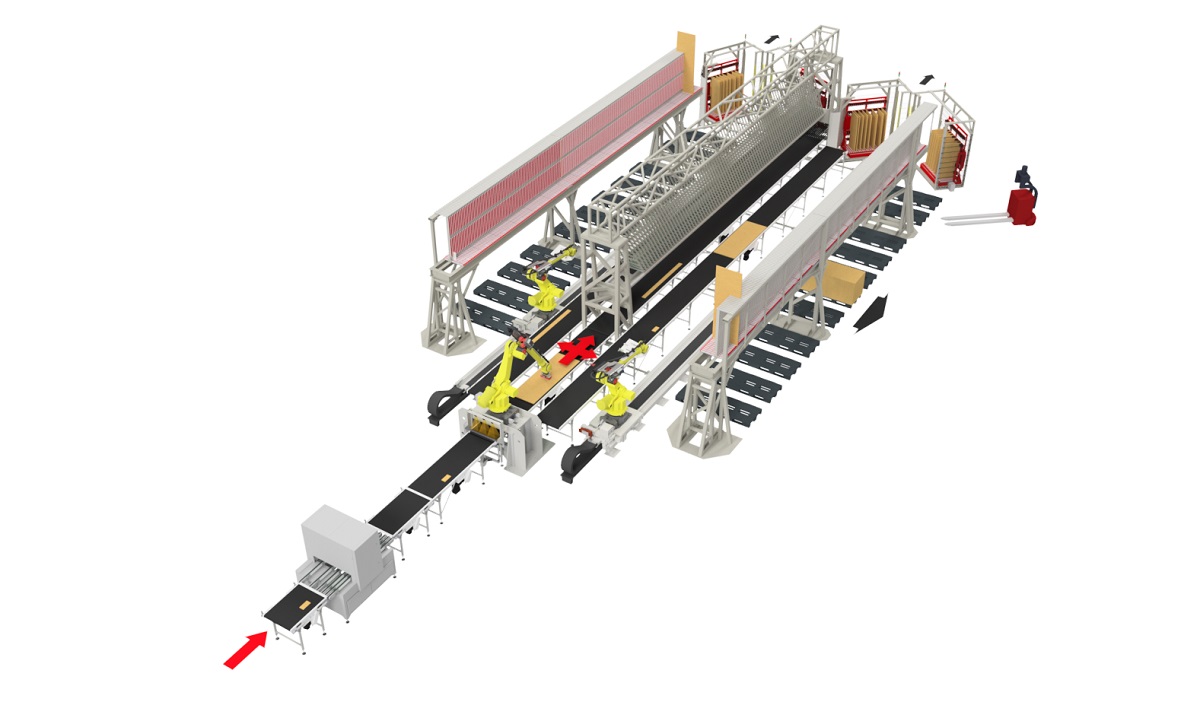

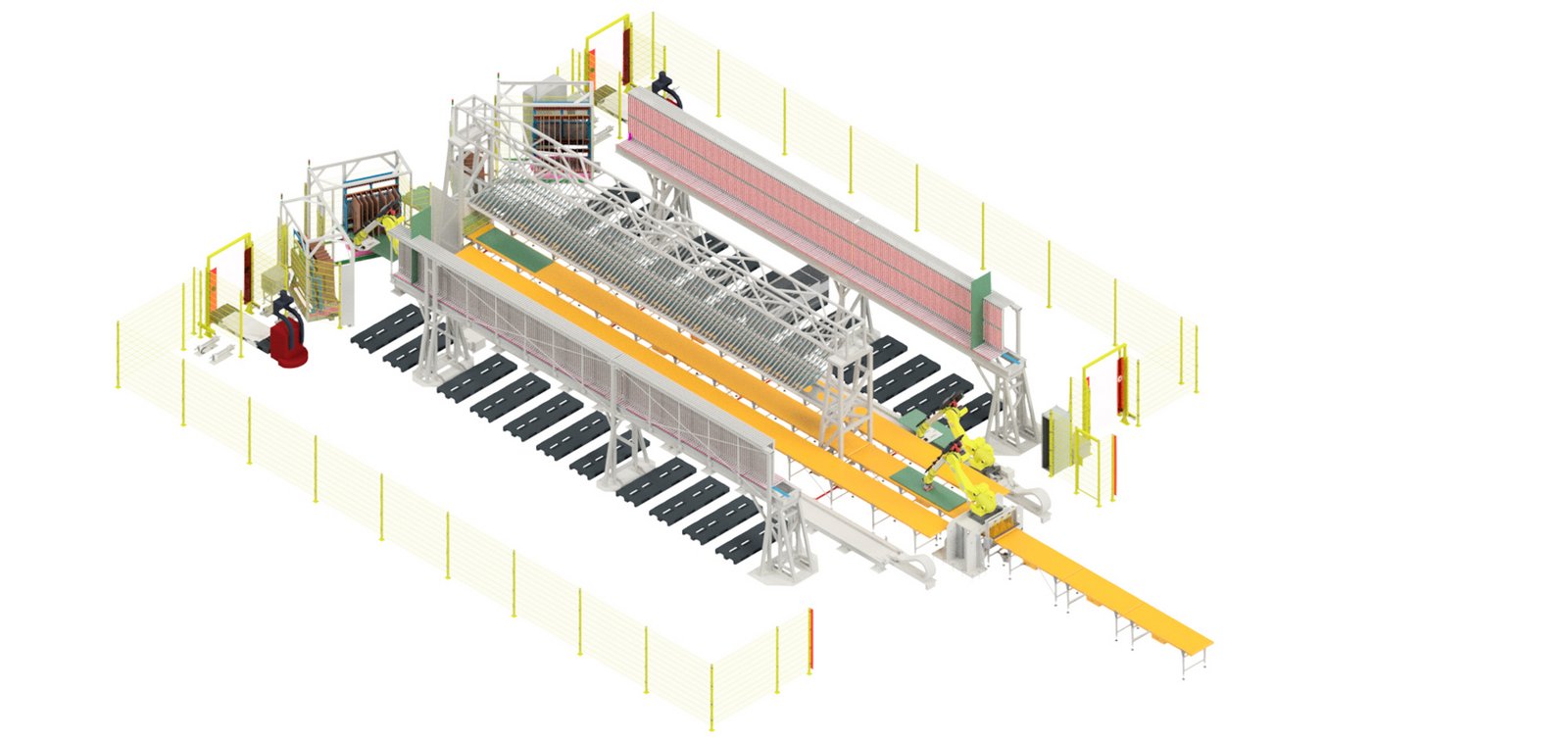

A non-continuous flow of furniture fronts is transferred from the previous line. At infeed, the parts are measured individually and the barcode is read. The actual data are compared with the stored data in the database of the production control system.

After this plausibility check, strategy software controls the flow of parts in the system with the aid of robots on linear axes, belt conveyors and racks. In this way, peak loads can be buffered depending on the situation and the available plant capacity can be used efficiently.

The aim of the system is to place furniture fronts of various dimensions on pallets according to an automatically generated packing pattern or stacking pattern. The transport of full and empty pallets is carried out by driverless transport vehicles.

![[Translate to English:] [Translate to English:]](/fileadmin/Seiteninhalt/Produkte/Branchenprodukte/Mobelindustrie/Kommissionieren_FTS_Burger__32_.jpg)