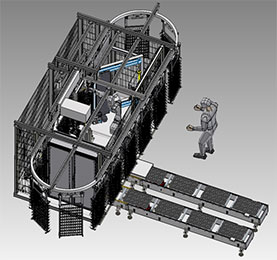

- Loading the racks

- Product supply sorted in trays or unsorted as bulk material

- Storage in the correct position

- Output arranged in boxes or as bulk material

- Digitized rack management

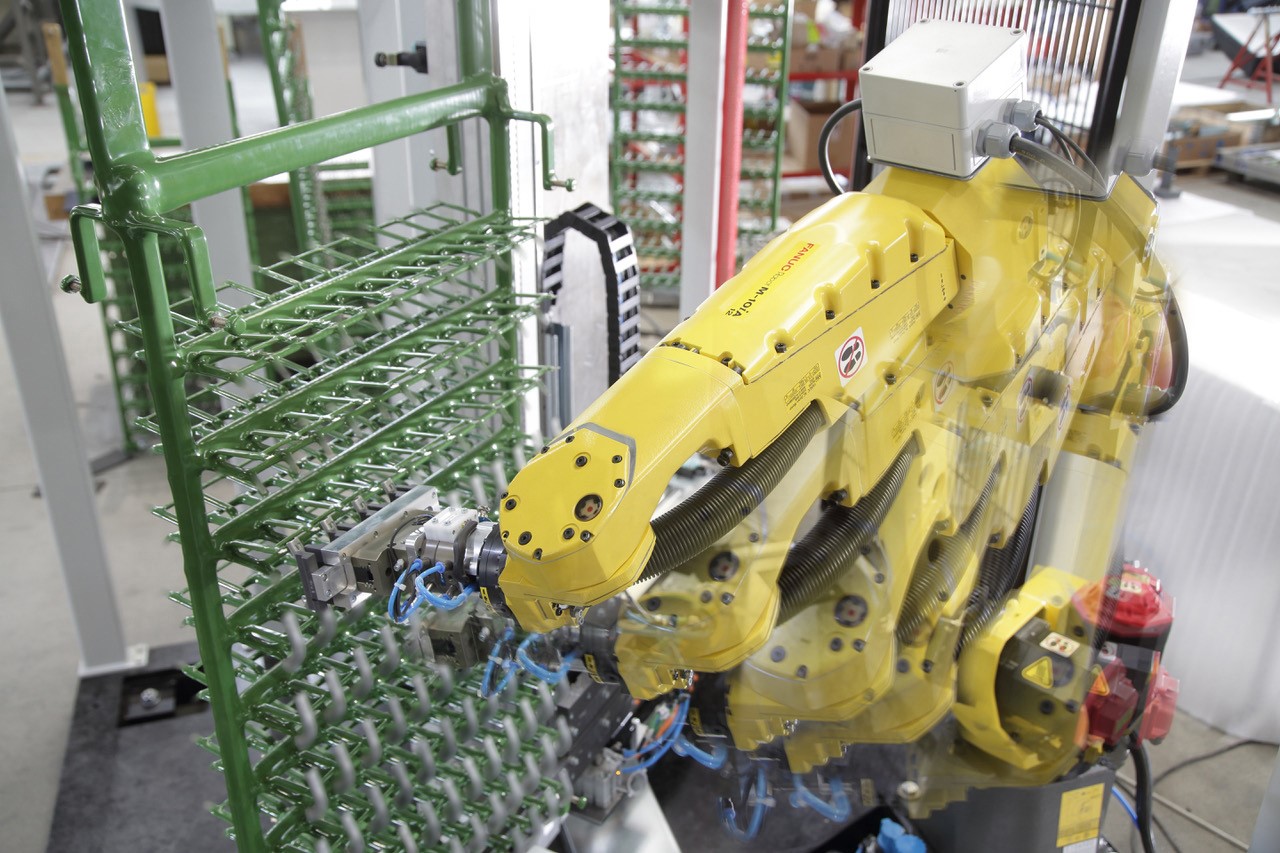

Description:

The placement system is used for the removal and placement of workpiece carriers such as electroplated,

anodized aluminum or titanium racks as well as KTL, washing, wet paint and powder racks.

The individual parts to be processed can be fed to the system as disordered bulk material or organized in trays and honeycombs.

The placement system enables unmanned work in multi-shift operation. The robots can control the removal and output of the component right up to its final packaging completely automatically. A final quality control is also possible completely automated. The system can be designed to different automation levels according to customer requirements.