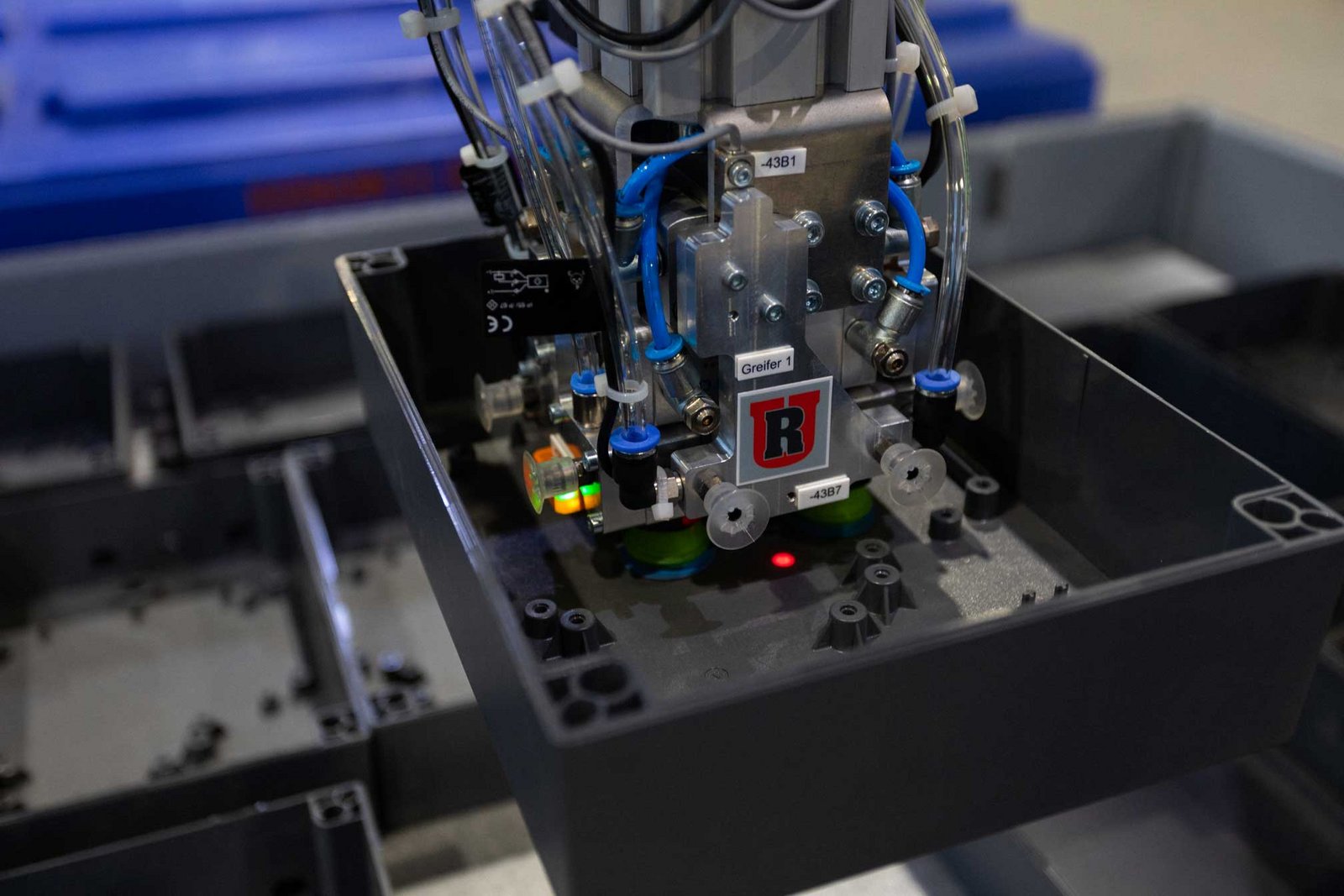

- Removal of product components from large load carriers including packaging handling

- Provision of the product components on workpiece carriers

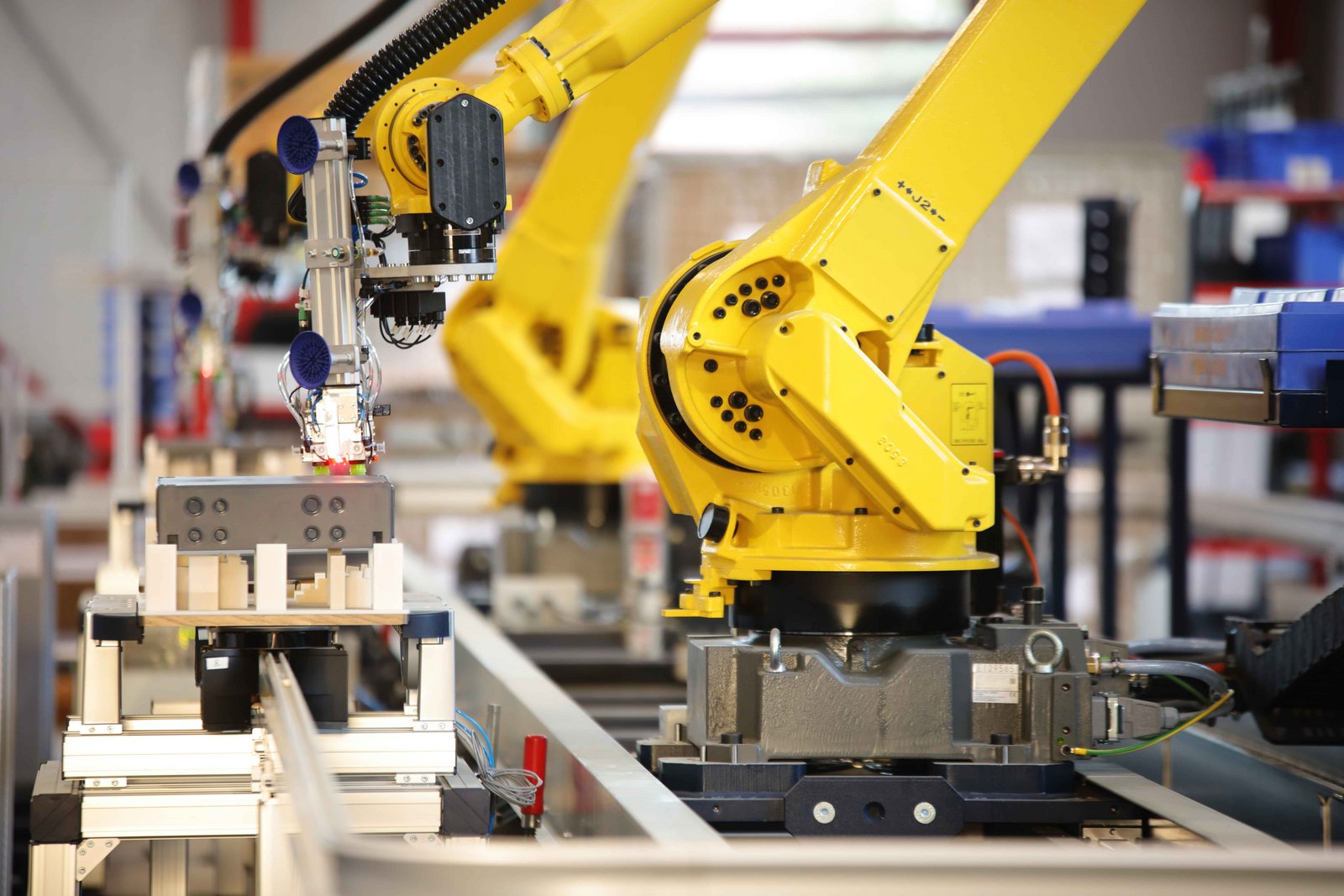

- Order parallel production with two robots with universal gripper on one traversing axis

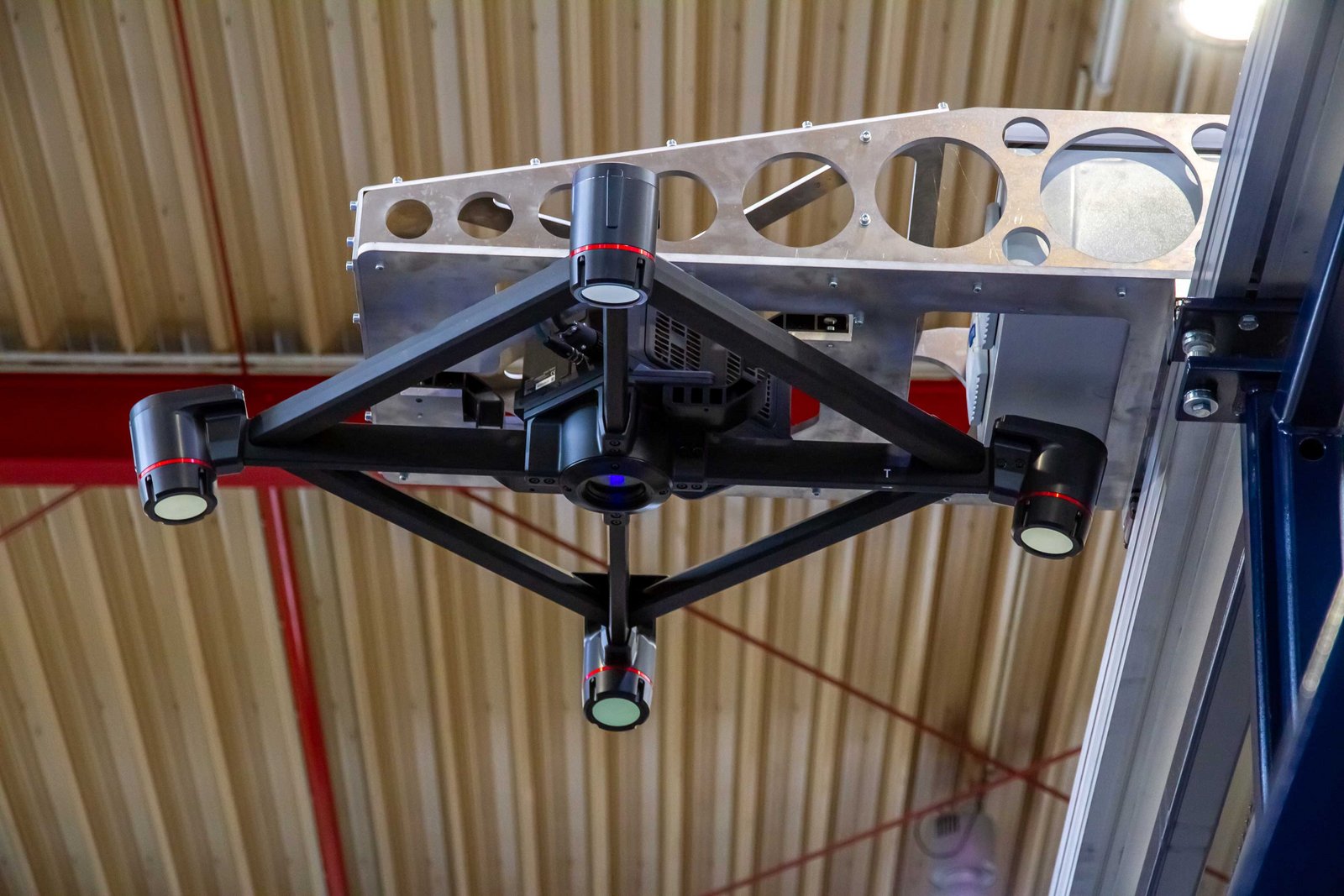

- Cycle time advantage through robot-independent 3D camera system on separate linear axis

- Communication with host computer

Description:

In the system for fully automatic order picking, product components are provided on workpiece carriers according to order, thus laying the foundation for subsequent assembly processes.

Ideally, the robotic cell is located at the beginning of an automated assembly line. This enables an optimal material flow and ensures a continuous supply to production. The system control communicates with the host computer and directs the robots and the camera system. Positioned above the load carriers, the 3D camera system supplies both robots with pick data. The two robots pick in parallel and usually process the picking orders together. For this purpose, they have identical universal grippers to handle all product components as well as covers of the load carriers and layer pads. Depending on the order, preparatory production steps, such as punching holes for downstream assembly work, can also be integrated into the cell.

The system is designed as a closed cell (aluminium profile system with protective screens) with several access doors and a safety light curtain for fast material supply. The material supply of the large load carriers is carried out either manually with industrial trucks or automatically with driverless transport systems (AGV).