- Automatic production of sealing collars

- High accuracy due to camera evaluation

- Precise feed due to servo-driven linear actuator connector

- Variable heating, cooling and pressing times

Description:

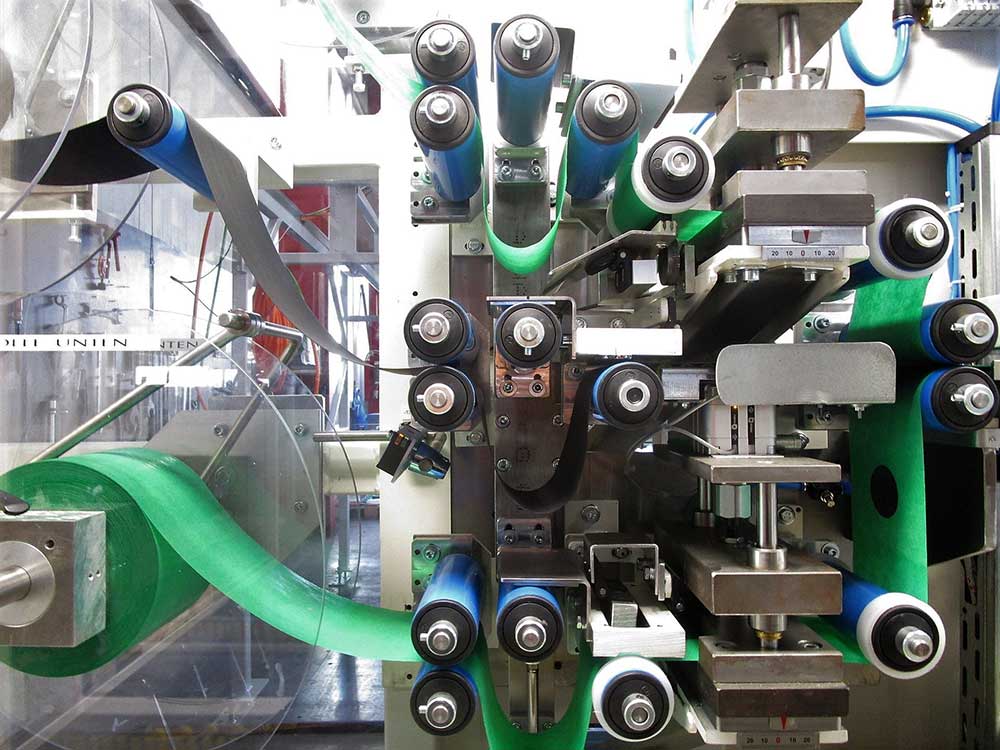

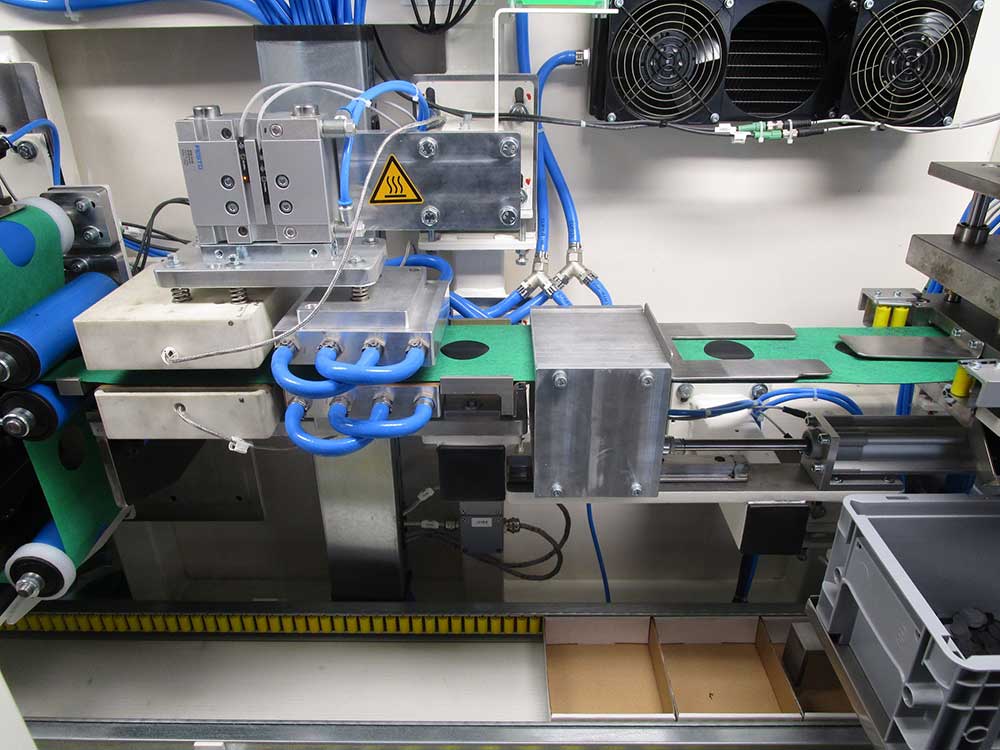

Production of sealing collars from 2 fleece layers and one EPDM layer. The sealing collar system is equipped with three pneumatically-operated hole punches and a pneumatically-operated cutting knife. A linear actuator connector driven by a servo motor serves as a feed. In connection with a built-in camera system, a high positioning accuracy can be guaranteed. The feed-in uses roller material. The 3 layers are pulled off the roll, punched individually and brought together. They are then laminated under a heating press. The extraction gripper pulls the sealing collars to the desired length and cuts them off. The finished sealing collars are picked up by a vacuum gripper and packed into cardboard boxes on a conveyor line.