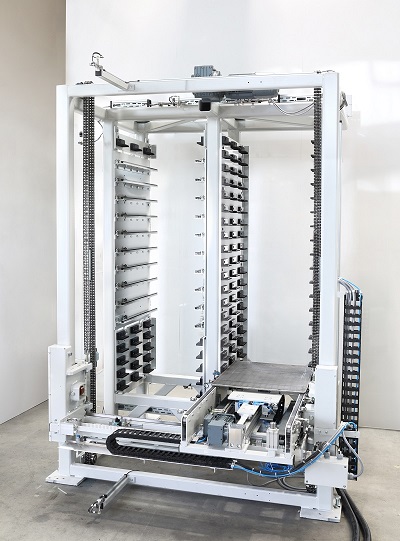

- Intermediate storage and provision of the press packs

- Lifting table for loading and unloading the storage unit

Description:

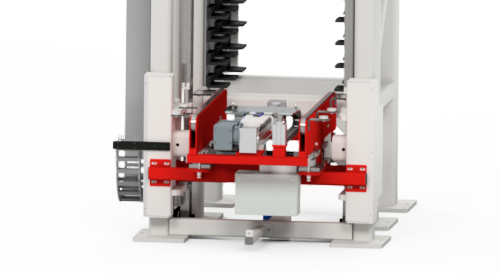

The high throughput rates of multi-daylight press technology can only be achieved with upstream and downstream storage units for the laid and pressed dies. The lifting table is equipped with a driven chain conveyor and a motor-driven insertion and extraction device.

During the pressing cycles, the subsequent order can already be pre-picked again with the lifting table. The single accumulator as well as the tandem accumulator are available for the individual tasks of the different press laminates. Dimensions, payloads and number of tiers depend on the specific task of our customers and are adapted to the requirements as needed.