- customized mixer feeding

- Design according to customer requirements

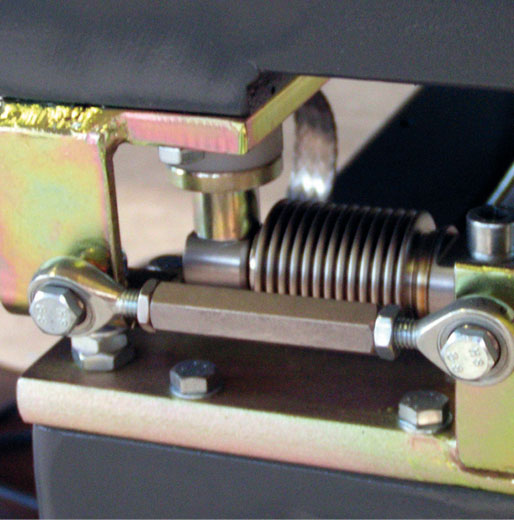

- precise weighing technology with 4 integrated load cells

- Compact drive technology with powerful drum motors

Description:

The mixing components are weighed via 4 weighing cells. When the target weight is reached, the weighing belt transfers the material to a buffer and supply belt for efficient feeding of your plant. All dimensions and belt speeds can be individually adapted to your production requirements.