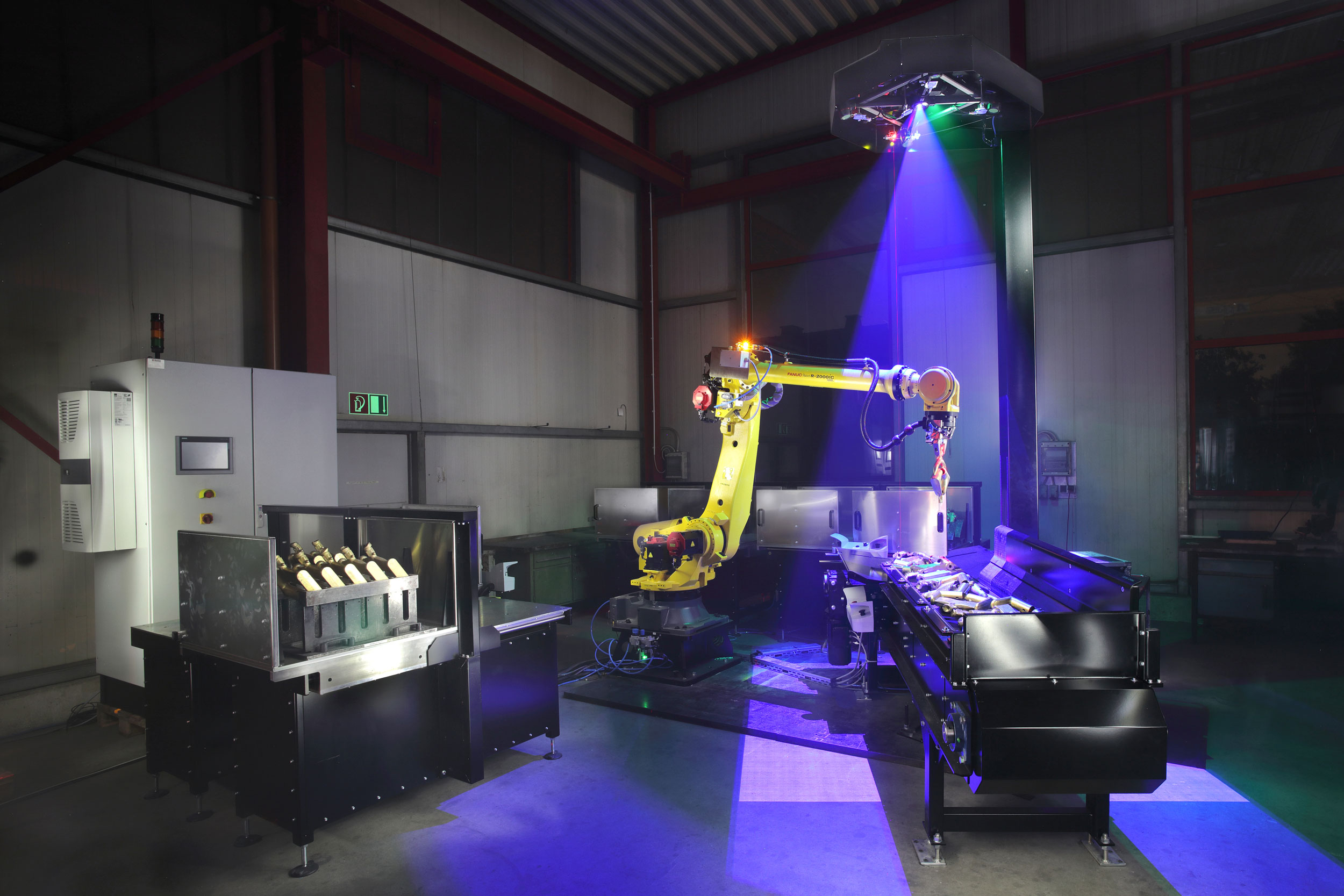

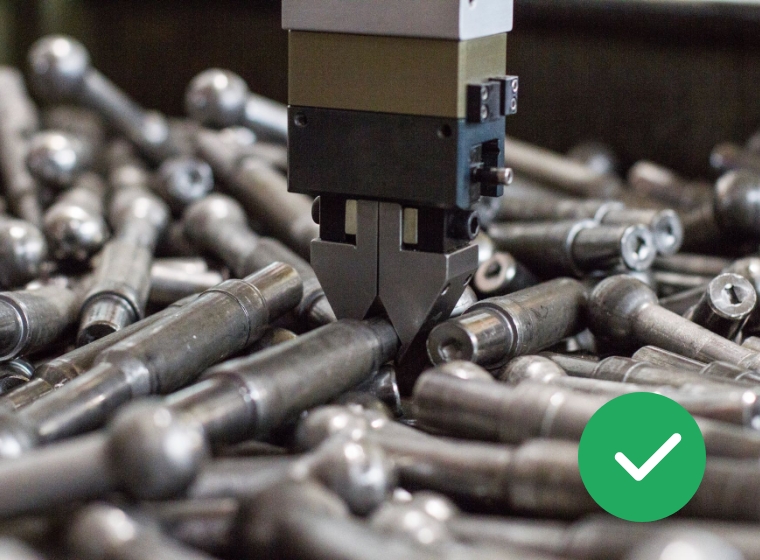

Precise and reliable Bin Picking

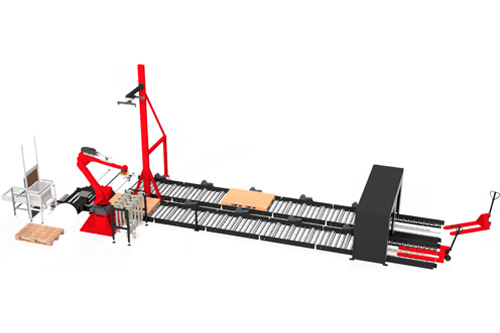

In modern industrial production, every second counts. Companies are increasingly faced with the challenge of automating processes to remain competitive and actively address the skilled labor shortage. This is exactly where Rotte’s CAMGripX-1200 Bin Picking Cell comes in. It opens a new dimension in the automated isolation of bulk material—fast, flexible, and reliable. Thanks to cutting-edge image processing with 3D camera technology, it masters even complex tasks with impressive precision and efficiency.