Robotic Order Picking: Efficient Automation for Precise and Flexible Logistics with Customized Picking Robots

In modern logistics and manufacturing, the automation of picking processes is becoming increasingly essential. Rotte’s picking robots can

In modern logistics and manufacturing, the automation of picking processes is becoming increasingly essential. Rotte’s picking robots can

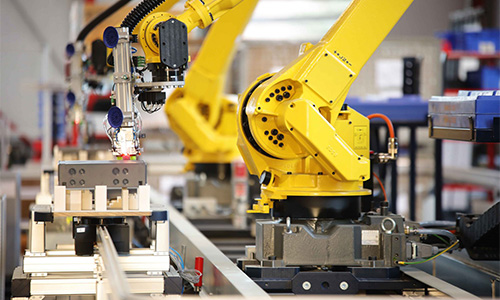

Picking is one of the most critical processes in warehouses and production halls. Whether in industrial manufacturing, e-commerce, or the automotive sector—whether stacking or pick-and-place—our robots ensure that objects of all kinds are provided in the correct quantity, at the right time, and in the proper location. Manual processes, however, often reach their limits—especially when it comes to large volumes, varying product shapes, or complex storage structures.

With next-generation robotic picking, we offer tailored automation solutions for the precise, flexible, and efficient picking of goods and components. Thanks to state-of-the-art 3D camera technology, intelligent control systems, and adaptive gripping tools, our systems can reliably detect, pick, and sort even unsorted or chaotically stored products.

Our robotic picking systems ensure faster, error-free, and resource-saving order assembly. With the integration of AI, 3D image processing, and automated grippers, our robots can:

The result: significantly higher productivity with reduced error rates and minimal manual intervention.

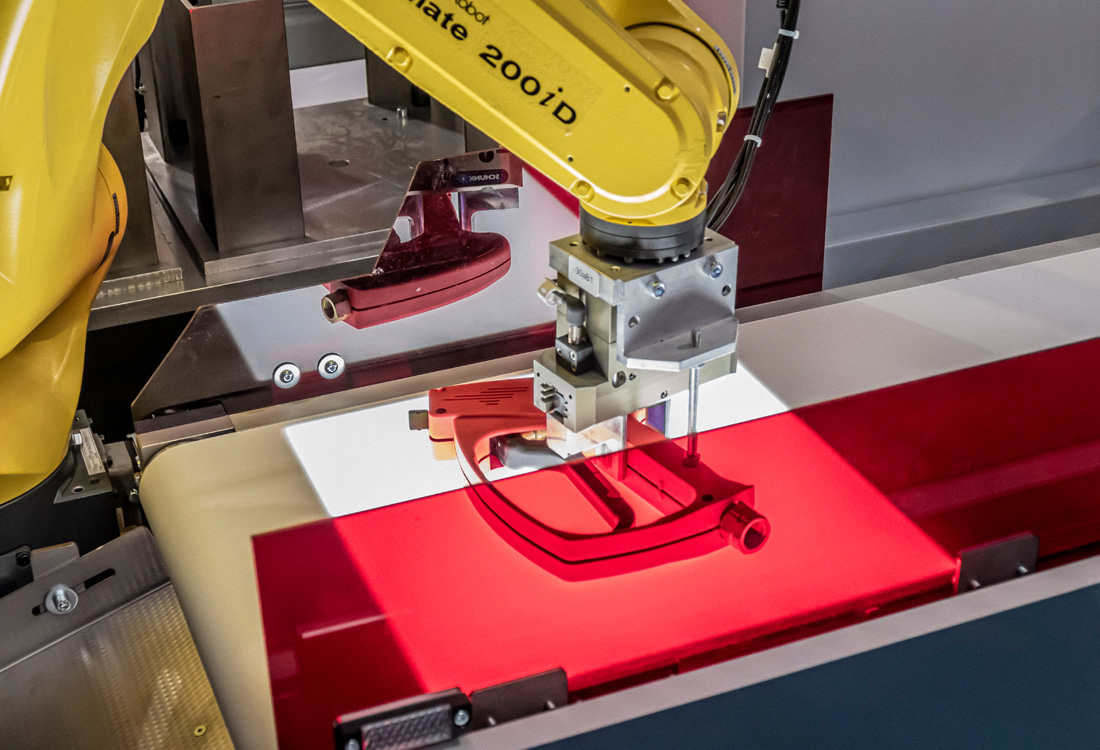

| Products | Injection moulded parts (>10 variants) |

| Product provision | 14 parking spaces with large load carriers |

| Robot | 2x Fanuc M-710C / 45 on 13 m traversing axis |

| Camera | Keyence 3D Robot Vision System RB-1200 on 15 m linear axis |

| Gripper on the robot | Universal gripper |

| Other tools | Pneumatic hole punch |

| Cycle time | less than 30 seconds (depending on product) |

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationOur robotic picking solutions integrate easily into existing warehouse, conveyor, and packaging systems. With modern interface technology, they can:

The fully automated control system adapts dynamically to changing demands—enabling greater scalability and long-term viability.

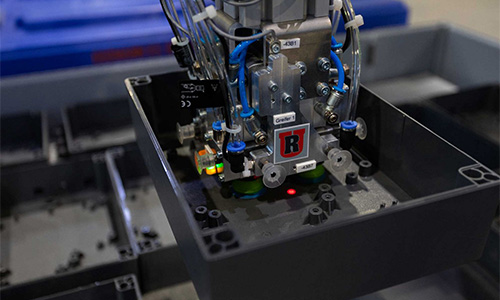

Alongside image recognition, the gripper is critical for effective picking. Our systems are equipped with flexible and customisable gripping technologies that vary depending on the product requirements. Vacuum grippers are ideal for delicate or large-area products, while mechanical grippers handle robust or heavy components safely. Magnetic grippers are used for metallic objects, and multiple grippers enable several items to be removed at the same time, thereby increasing the process speed. Thanks to automatic gripper changing, our robots can pick a wide variety of products within a single system, ensuring maximum flexibility and efficiency.

Our robotic solutions combine intelligent vision systems, precise gripping technologies, and advanced controls to enable reliable, flexible, and scalable automation.

3D Camera Systems for Precise Bin Picking

A key element of our robotic picking technology is 3D camera vision, enabling the exact identification and localization of components and products. Thanks to intelligent image processing, the system can depalletise and palletise products autonomously, identify objects regardless of their position or stacking, record depth information in order to reliably grip concealed or overlapping items and analyse shape, size and material properties in order to select the appropriate gripping mechanism. These AI-supported functions make unsorted or chaotic warehouse structures accessible to robots and enable autonomous, high-precision picking.

Automated robotic picking offers major advantages across many industries—especially for businesses dealing with high volumes, variable product forms, and demanding logistics operations.

In distribution centers and e-commerce warehouses, our robots quickly and accurately pick heterogeneous products from various zones, sort them, and prepare them for shipment—reducing delivery times and minimizing errors.

In automotive and mechanical engineering, our systems ensure the precise provision and handling of components, with small parts and assembly kits picked and fed directly into production lines.

In pharma and medical technology, our robots deliver hygienic and highly accurate picking of medications and medical products that must meet the highest quality standards.

In the electronics industry, our intelligent gripping systems and sensitive robotic arms ensure the safe handling of delicate electronic components without damage.

Automated robotic picking offers major advantages across many industries—especially for businesses dealing with high volumes, variable product forms, and demanding logistics operations.

In distribution centers and e-commerce warehouses, our robots quickly and accurately pick heterogeneous products from various zones, sort them, and prepare them for shipment—reducing delivery times and minimizing errors.

In automotive and mechanical engineering, our systems ensure the precise provision and handling of components, with small parts and assembly kits picked and fed directly into production lines.

In pharma and medical technology, our robots deliver hygienic and highly accurate picking of medications and medical products that must meet the highest quality standards.

In the electronics industry, our intelligent gripping systems and sensitive robotic arms ensure the safe handling of delicate electronic components without damage.

In intralogistics and production, robotic order picking is the most efficient, secure, and often the most economical method for automated material handling and order assembly. It increases productivity, reduces errors, and leads to long-term optimization of your logistics processes.

Contact us today to discuss your personalized, high-performance robotic picking solution!

Ulrich Rotte Anlagenbau & Fördertechnik GmbH is your specialist in custom machinery. In addition to our innovative solutions in special-purpose machinery and automation technology, you also benefit from a wide range of customer and after-sales services:

– und keine Neuigkeiten mehr verpassen! Erhalten Sie regelmäßig spannende Einblicke, aktuelle Informationen und exklusive Angebote direkt in Ihr Postfach. So bleiben Sie immer auf dem neuesten Stand.

– and never miss any news again! Receive exciting insights, the latest information and exclusive offers directly in your inbox on a regular basis. This way, you will always be up to date.

You are currently viewing a placeholder content from Vimeo. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou need to load content from reCAPTCHA to submit the form. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from Google Maps. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from Google Maps. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from Mapbox. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from OpenStreetMap. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou need to load content from reCAPTCHA to submit the form. Please note that doing so will share data with third-party providers.

More Information