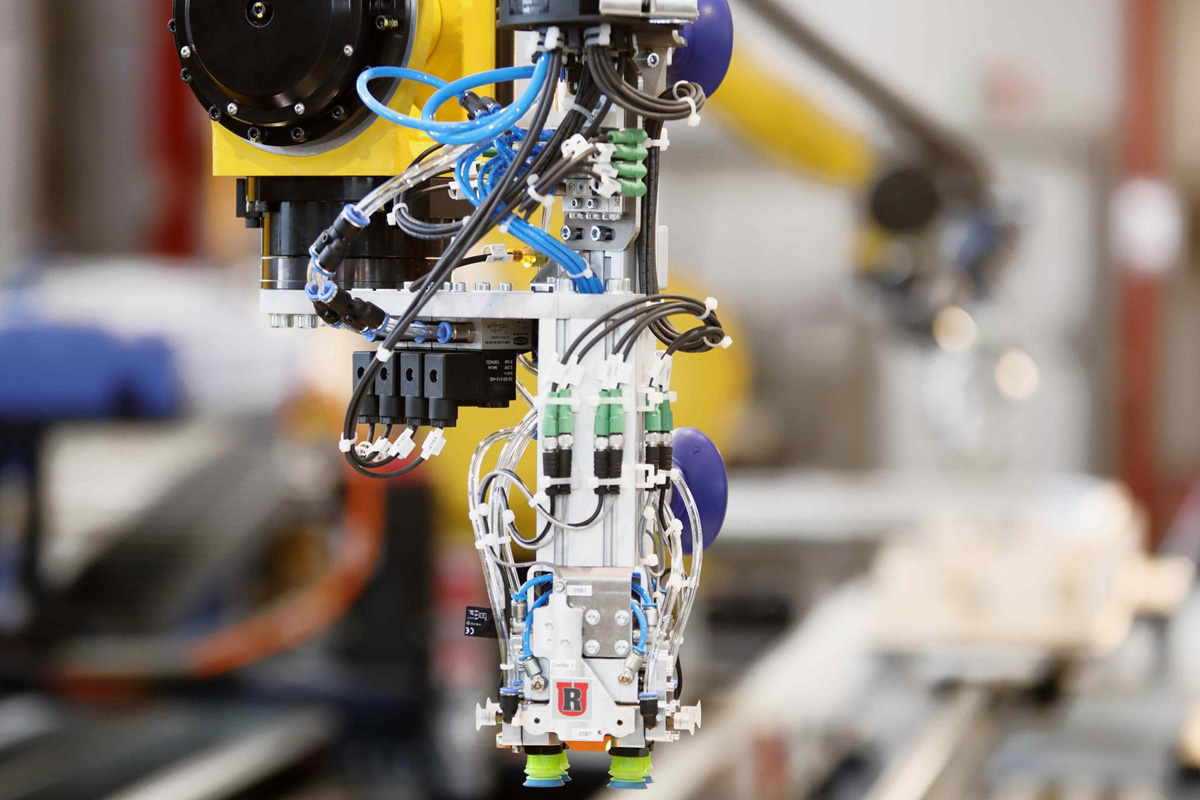

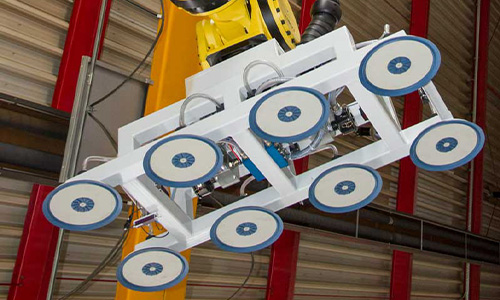

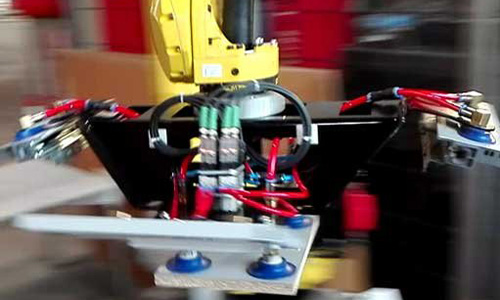

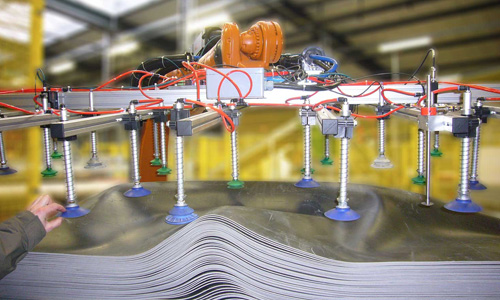

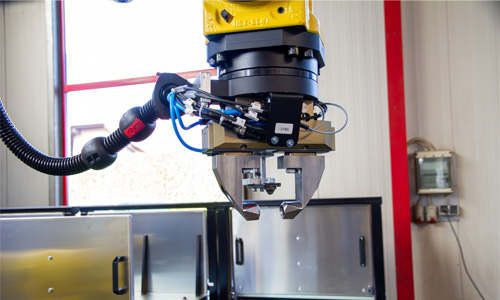

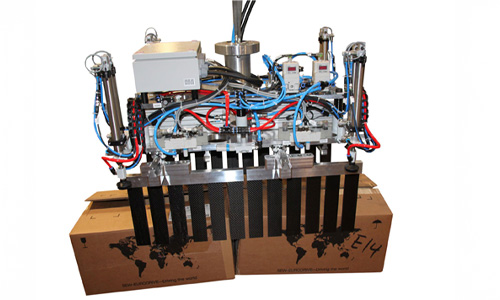

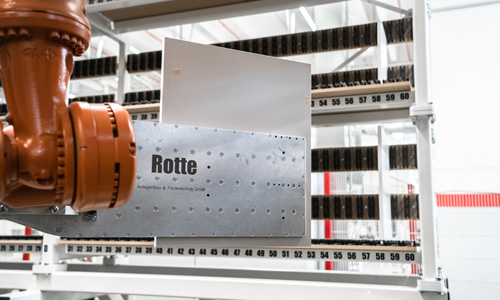

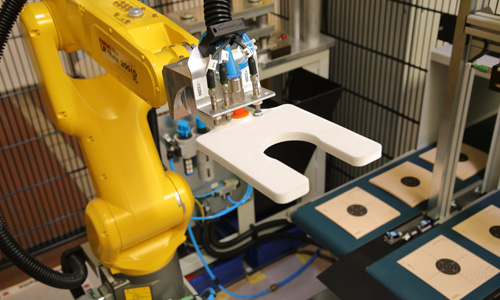

Perfect handling starts with the right gripper

We equip your robots, cobots, and robotic cells with custom solutions for precise handling of components and workpieces. A robotic system only reaches its full automation potential with the right gripper. Rotte designs and manufactures custom grippers that are tailored exactly to the individual requirements of our clients, becoming truly flexible and efficient solutions for complex handling tasks.