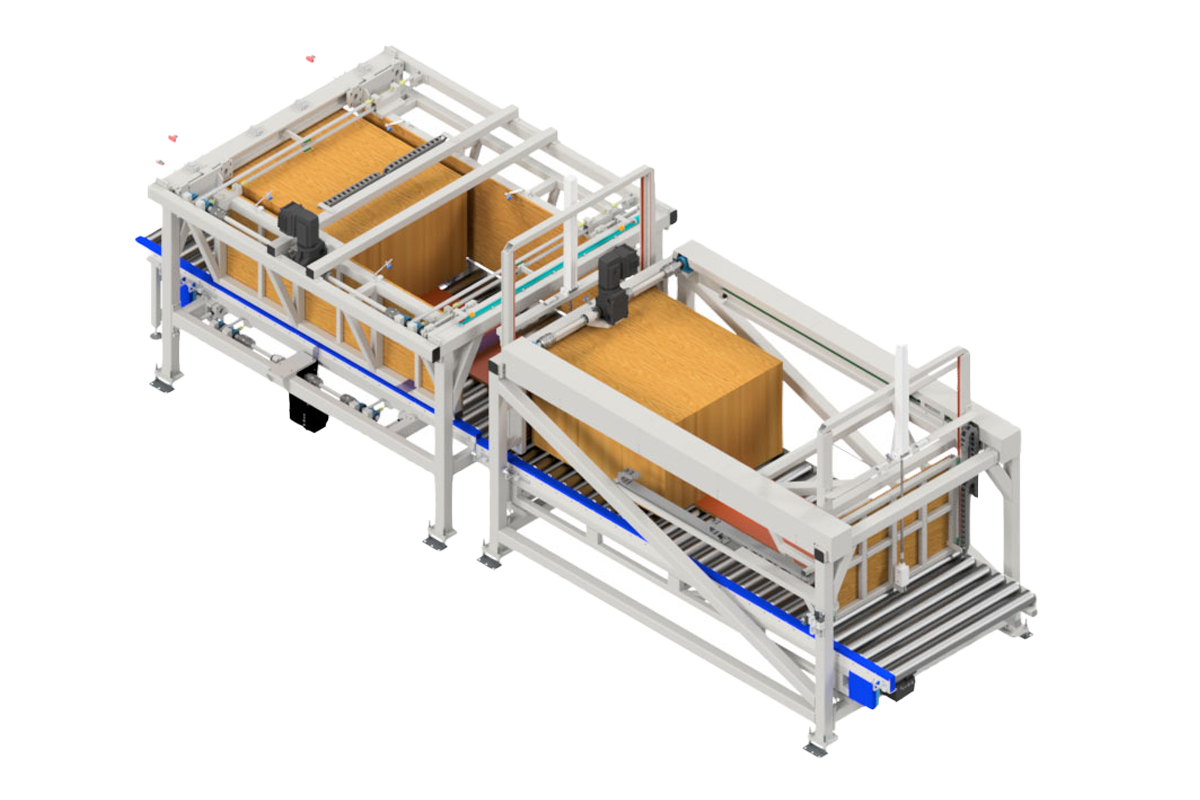

Precision in flow – the right solution for every position

Rotte alignment stations ensure exact positioning of products and components to keep downstream processes running smoothly. In many production and logistics operations, precise alignment is essential—for example, with stacked sheet materials, household appliances, or other large-format components. Defined positioning increases process reliability, reduces error rates, and enables efficient further processing.