Building Components Industry

Automated Manufacturing of Building Components – with Innovative Technologies from Rotte

Rotte develops custom automation and special-purpose machinery solutions for manufacturers of building components. Whether for PVC windows, aluminum façades, front doors, or modular construction parts—we provide the right technology to accelerate your processes, safeguard your quality, and future-proof your production.

Rotte develops custom automation and special-purpose machinery solutions for manufacturers of building components. Whether for PVC windows, aluminum façades, front doors, or modular construction parts—we provide the right technology to accelerate your processes, safeguard your quality, and future-proof your production.

Contact us now to receive expert advice on your custom machines and systems!

Your contact person

Daniel Bürgermeister

Technical sales & project planning

Special Machines for Building Components – Flexible, Efficient, Customized

Building components are as diverse as the buildings they’re installed in. Standardized manufacturing solutions often fall short. That’s why our team develops systems precisely tailored to your products, cycle times, materials, and assembly processes—fully addressing the diversity of your industry.

Our solutions are used across a wide range of applications in the manufacturing of building components and cover an extensive spectrum of high-quality products and complex processes. They are employed in the production of doors and windows made from PVC, aluminum, or composite materials, as well as for rolling and sectional garage doors, awnings, façade elements, mullion-transom systems, and a wide variety of accessories. Our technologies also efficiently support the processing of insulating glass and thermal insulation systems.

The focus is on automating core processing steps within the production chain. Our systems handle profile processing and the precise feeding of raw materials. Cutting, drilling, milling, and welding of components can be fully automated. We also integrate automated assembly processes for fittings, seals, and glass elements, combined with reliable bonding, screwing, pressing, and sealing technologies.

To ensure a smooth material flow, we provide solutions for conveying, buffering, sorting, and stacking components. Finally, our systems take over end-of-line inspection and packaging of finished elements—ensuring a continuous, efficient, and high-quality production process.

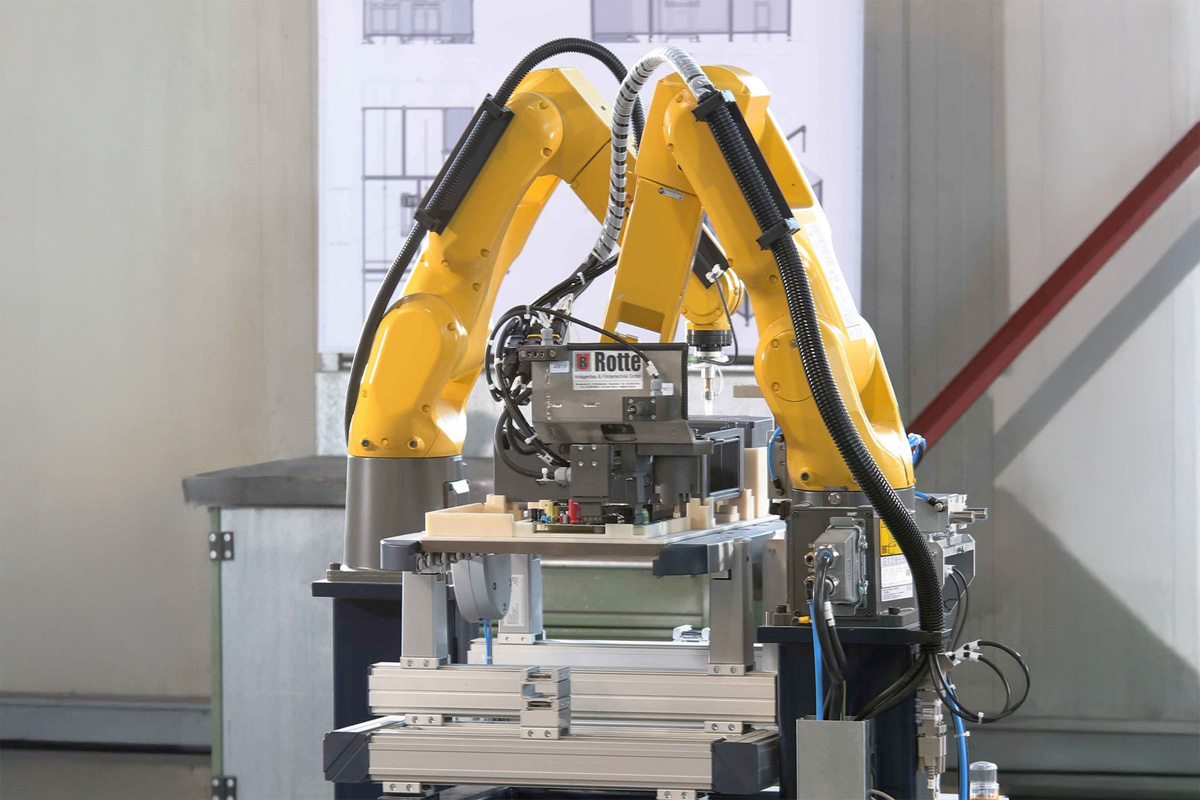

Robotics & Vision Systems for Complex Geometries and Changing Variants

Especially in the case of diverse building components within broad product portfolios, it’s essential to intelligently control automated processes and flexibly respond to varying dimensions, shapes, or equipment versions. For this, Rotte combines advanced robotics with powerful industrial vision systems to identify components, position them precisely, and process them with consistent quality.

The combination of robotics and vision technology enables highly customizable manufacturing—with no compromises on cycle times or process reliability.

Our solutions include:

- Pick-and-place robots for handling profiles, glass panels, or small parts

- Camera and sensor systems for position detection and quality control

- Flexible assembly cells for different element sizes and shapes

- Robot applications for the application of sealants, adhesives or assembly kits

Conveyor and Transport Systems for Large, Delicate Components

As a full-service provider for turnkey production lines, Rotte develops and implements holistic solutions tailored precisely to your requirements for cycle time, product variety, and process quality. We support you from the first concept well beyond commissioning—with comprehensive services from a single source.

At the core is the individual consultation and planning of a manufacturing concept that integrates seamlessly into your processes. We then handle the design and production of all mechanical and electrical components—precisely, reliably, and with the highest quality standards. Modern control technology and vision systems are integrated along with all necessary interfaces to higher-level systems.

Assembly, commissioning, and employee training take place directly on your premises to ensure a smooth production start. And even after that, we remain by your side—with long-term service, regular maintenance, and ongoing system optimization.

Whether you are building a new facility, expanding existing lines, or targeting the automation of specific tasks—with Rotte, you’re choosing industry-leading expertise and a partner who speaks your language, understands your needs, and thinks holistically about your processes. Let us advise you personally—today!

Conveyor and Transport Systems for Large, Delicate Components

Elements like window frames, façade profiles, or door panels are often bulky, fragile, and heavy. For smooth and safe material flow, we develop specialized conveyor systems that ensure optimal handling and logistical efficiency.

We ensure seamless, synchronized, and gentle movement of your products—from raw material input to final logistics units.

Our technology includes:

- Chain, roller, and belt conveyors specifically for profile and flat material transport

- Rotation stations, lift units, and transfer systems for complex production steps

- Buffer and sorting systems aligned with your production logic

- Material flow solutions for preassembled and fully finished components

- Integration with storage and shipping areas via automated interfaces

One Company, Many Advantages

Ulrich Rotte Anlagenbau & Fördertechnik GmbH is your specialist in custom machinery. In addition to our innovative solutions in special-purpose machinery and automation technology, you also benefit from a wide range of customer and after-sales services:

Your Advantages at a Glance:

- Decades of experience in special-purpose machinery

- Extensive know-how across all areas of automation technology

- High expertise in the latest technologies and applications for Industry 4.0

- All services from a single source—from development and design to manufacturing, assembly, commissioning, and regular on-site maintenance

- Optional training of your machine operators, technicians, and supervisors at your facility

- Mechanical engineering made in Germany – we design and manufacture exclusively in Germany

- Personalized customer support – you will always have a qualified contact person available

Our products

Industrial Measurement Technology & Automation

Customized Measurement Systems for Your Business Precision measurement technology is a fundamental component of modern ...

Drum Turner

When Everything Revolves Around Your Workpieces Turners for panels of all material types: In many ...

Thermoforming Machine

Precision meets innovation – thermoforming technology for demanding fibre materials For the industrial processing of ...

Picking Robots

Robotic Order Picking: Efficient Automation for Precise and Flexible Logistics with Customized Picking Robots In ...

In-Line and End-of-Line Testing

The implementation of automated End-of-Line (EOL) and In-Line testing systems enables companies to make their ...