Renewable Energy

Custom Plant and Machinery Solutions for Photovoltaics and Other Renewable Energy Sources

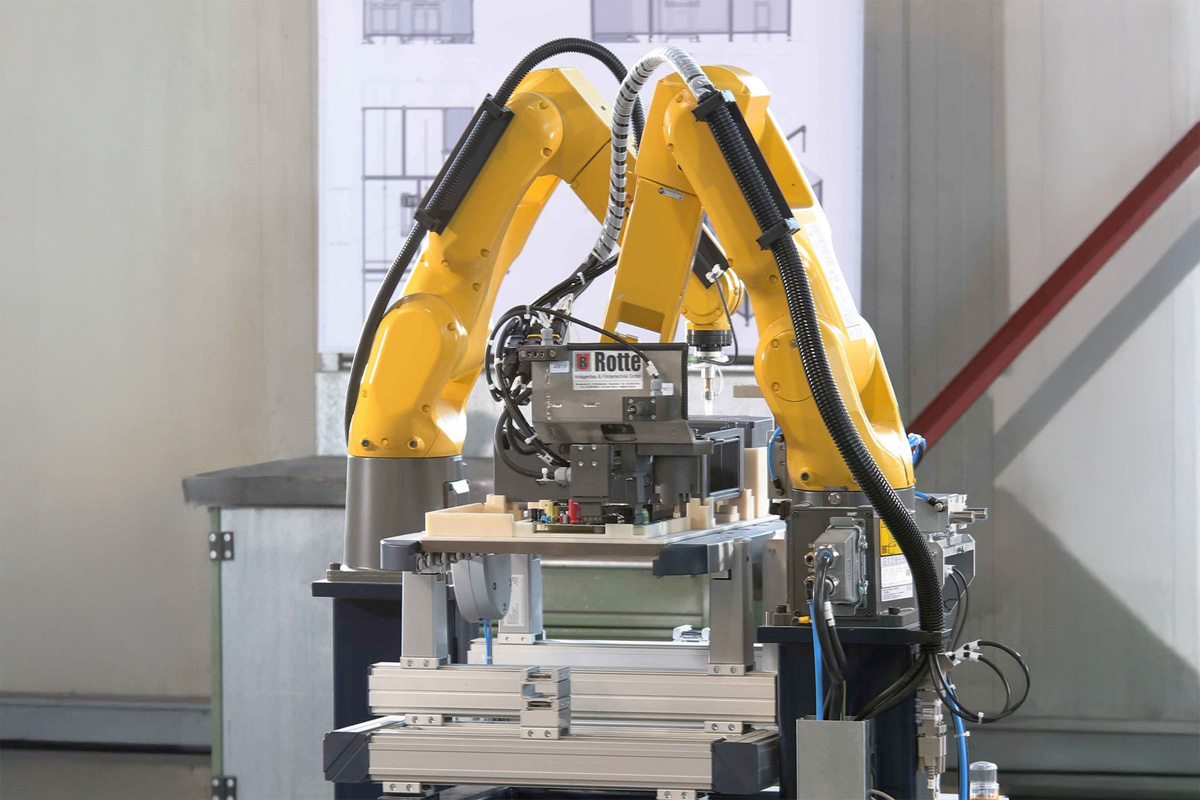

The sustainable energy supply of the future relies on renewable energy—and on powerful, efficient, and precisely coordinated production processes. As an experienced specialist in custom machine building, Rotte develops intelligent, automated solutions for the production and processing of components in photovoltaics, wind power, hydrogen technology, and energy storage. Our tailor-made systems are used by leading technology manufacturers and make a significant contribution to production reliability, increased efficiency, and ongoing technological advancement.

We see ourselves as a partner in the energy transition. With our expertise in automation and conveyor technology, as well as in the development of complex custom machinery, we support our clients in the renewable energy sector from planning to turnkey delivery. Our custom-built systems meet the highest standards for precision, repeatability, and process reliability—and they are flexible enough to remain effective in future innovation cycles.

Contact us and shape your green production of tomorrow with Rotte.

Your contact person

Daniel Bürgermeister

Technical sales & project planning

Wind Power

Green capital goods have long been part of our portfolio—such as winding systems for wind power technology.

Hydrogen

Storing renewable energy is key to the energy transition. We deliver suitable plant concepts for this purpose.

PV Industry

Our 2D line tracking and 3D vision systems (including bin picking applications) provide reliable part detection, identification, and sorting for various component types.

Energy Storage

Whether it’s a stand-alone unit or a full production line—Rotte develops special-purpose machinery for your flexible production needs. Inventive engineering in service of our customers is our strength.

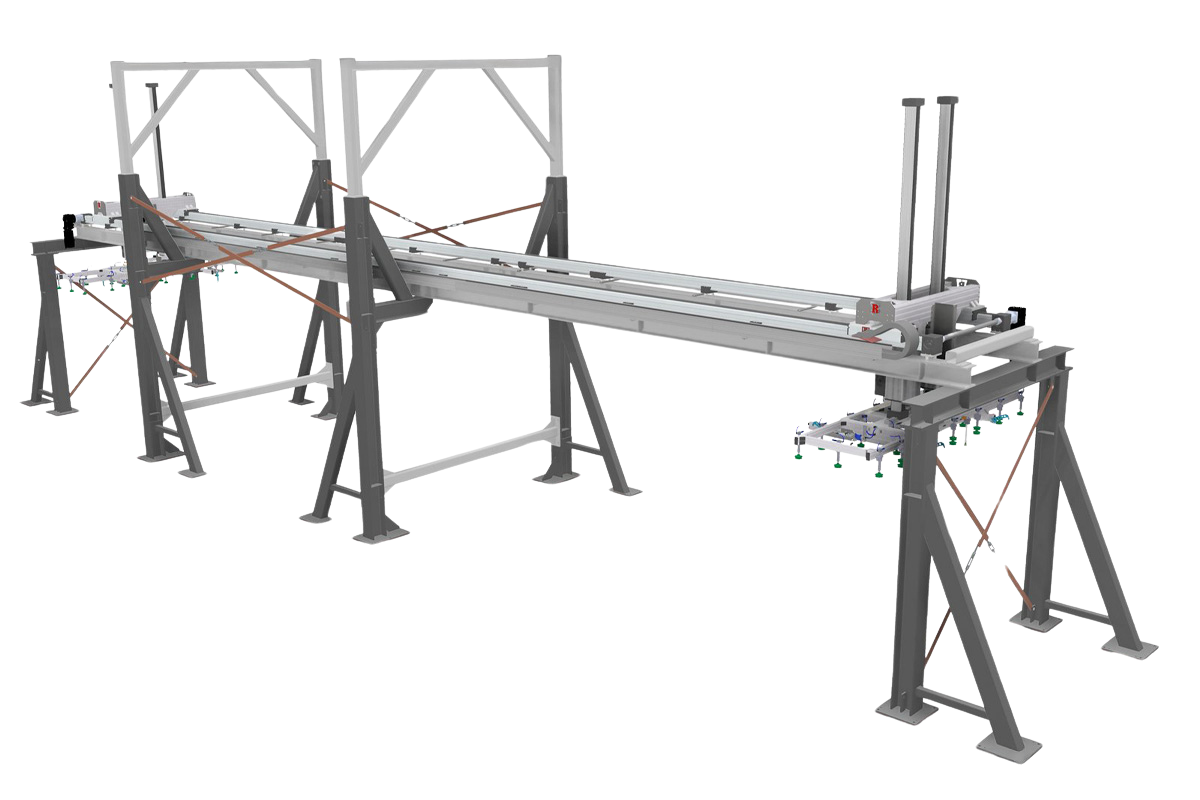

Automation Solutions for the Wind Power Industry

Wind energy is a key pillar of the energy transition—on land and at sea. With our customized special solutions, we support manufacturers of wind turbine components throughout the entire production chain. A particular focus is placed on our winding systems for rotor blade structures, which can be tailored to different geometries, materials, and component sizes.

With a high degree of automation, cycle times are reduced, scrap is minimized, and quality is standardized—all while maintaining maximum flexibility for different rotor blade designs.

Our systems handle tasks such as:

- Precise winding of fiber composite materials (e.g., GFRP or CFRP)

- Automated application of adhesives and sealants

- Handling of large-volume components with synchronized motion control

- Positioning and joining of complex geometries with real-time monitoring

Tailor-Made Machines and Systems for the Hydrogen Industry

The hydrogen economy demands high standards in automation technology—especially with regard to safety, process accuracy, and material handling. Our custom solutions for hydrogen-related production, storage, and processing offer future-ready systems for a growing technology market.

Our systems are used in the manufacturing of fuel cells, electrolyzers, and storage technologies.

Thanks to our expertise in robotics, conveyor systems, and machine vision, we provide fully integrated solutions that enhance operational efficiency across intralogistics, production, and process engineering. Our systems are scalable, modular, and easy to integrate into existing production environments. At the same time, our know-how enables you to build entire production lines as fully integrated system solutions.

Our System handle a wide range of tasks such as:

- Automated processing of bipolar plates, electrodes, and membranes

- Assembly of cell stacks with integrated sealing technology

- Processing of hydrogen-carrying components in inert or cleanroom environments

- Bonding and welding of sensitive assemblies with precise temperature and pressure control

- Robotic quality control using industrial image processing and sensor-based inspection

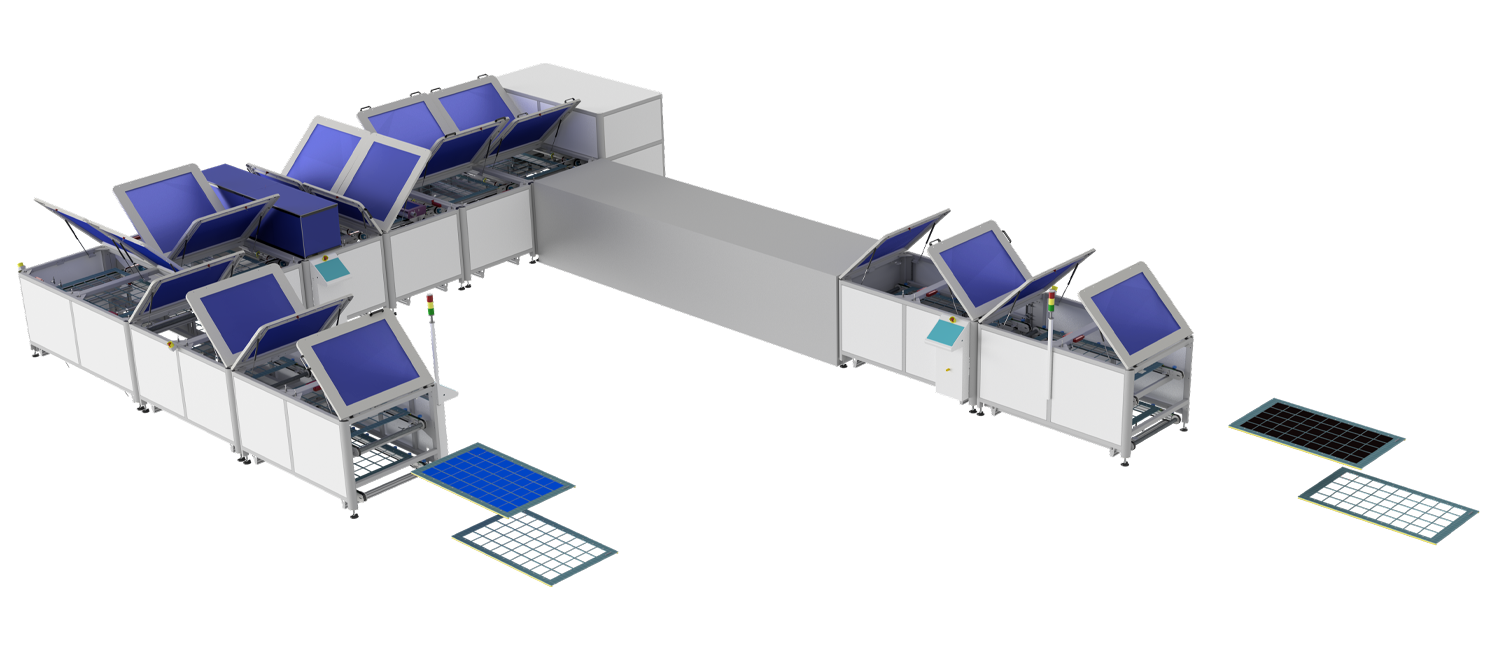

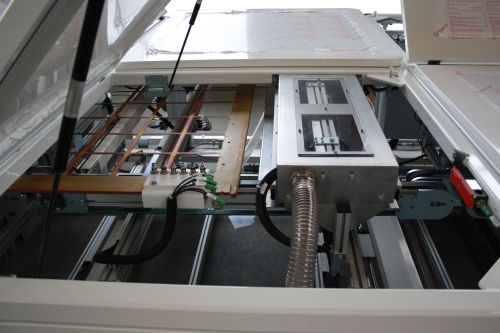

Individual solutions for the solar industry

The production of PV modules is characterized by high volumes, sensitive materials, and a need for consistently high quality. We offer fully automated systems for manufacturing solar cells and PV modules—from cell singulation and stringing to lamination and final packaging.

Where photovoltaic systems are driving greener mobility, supplying clean electricity to homes and businesses, and already accounting for nearly 20% of Germany’s electricity generation, Rotte’s custom production systems are enabling an even faster shift to a sustainable future. Our systems are tailored precisely to your product geometries and production capacities—with the goal of ensuring highly efficient, scalable, and future-proof manufacturing.

Our customers benefit from a wide range of capabilities:

- Complete solutions for line automation

- High-precision handling of fragile substrates

- Integrated image processing for quality control

- Smart robotic cells for assembly, sorting, and palletizing

- Modular systems for flexible plant expansion

Innovative solutions for energy storage

Storing renewable energy is essential to the success of the energy transition. Rotte develops automated manufacturing systems for battery storage technologies and other storage solutions designed to meet the highest demands for safety and performance.

The systems we develop can be flexibly adapted to various cell formats (e.g., pouch, cylindrical, or prismatic cells) and provide maximum process reliability with excellent scalability. Your ideas and goals are our highest priority at every stage of the project. The market demands increasingly more from available energy solutions. You should expect more from us.

Our capabilities in this field include:

- Systems for cell and module production (e.g., for lithium-ion or solid-state batteries)

- Assembly and inspection cells with integrated image processing

- Fully automated testing and sorting systems for energy storage components

- Custom production line layouts for small and large-scale manufacturing

Green Technology Needs Smart Machines – Rotte is at Your Side

The renewable energy sector is defined by rapid innovation, shifting markets, and growing international competition. Our custom-built machines and automation solutions help you future-proof your operations in this fast-paced environment. At the same time, automation paired with intelligent digital control technologies helps you maximize the potential of your workforce and use human labor more effectively.

Rotte’s strength lies in our exceptional manufacturing depth and ongoing collaboration with your team. From the initial concept to engineering, manufacturing, and commissioning, through to training, maintenance, and long-term support, we deliver everything from a single source.

Choose cutting-edge plant solutions that are precisely tailored to your specific products—and trust in the experience and innovative drive of Rotte. Reach out to us today by phone, email, or via our callback form. We’ll be happy to provide you with a no-obligation, cost-free quote.

One Company, Many Advantages

Ulrich Rotte Anlagenbau & Fördertechnik GmbH is your specialist in custom machinery. In addition to our innovative solutions in special-purpose machinery and automation technology, you also benefit from a wide range of customer and after-sales services:

Your Advantages at a Glance:

- Decades of experience in special-purpose machinery

- Extensive know-how across all areas of automation technology

- High expertise in the latest technologies and applications for Industry 4.0

- All services from a single source—from development and design to manufacturing, assembly, commissioning, and regular on-site maintenance

- Optional training of your machine operators, technicians, and supervisors at your facility

- Mechanical engineering made in Germany – we design and manufacture exclusively in Germany

- Personalized customer support – you will always have a qualified contact person available

Our products

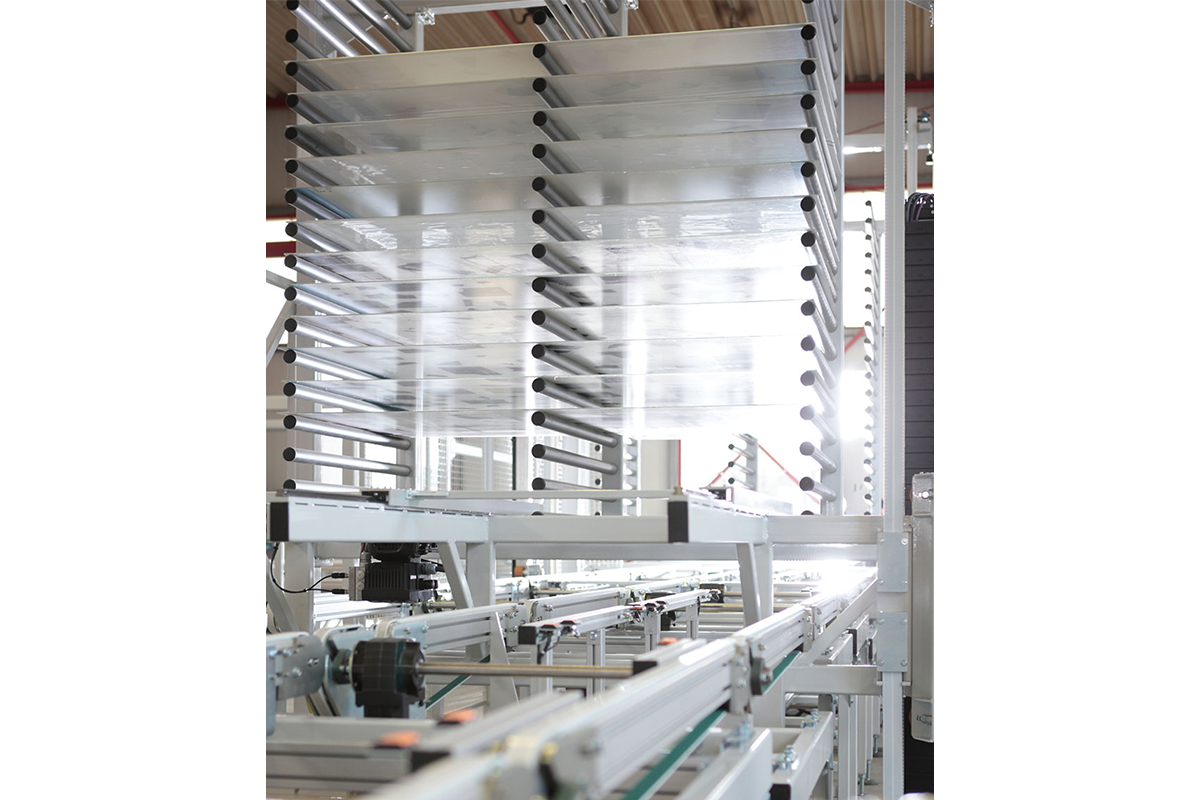

Automated Storage Systems for Multi-Daylight Presses

Perfect handling starts with the right gripper In high-output production processes involving multi-daylight presses, efficient ...

Picking Robots

Robotic Order Picking: Efficient Automation for Precise and Flexible Logistics with Customized Picking Robots In ...

FIFO Storage Systems

Intelligent material flow technology for trouble-free, automated production Rotte develops efficient material flow systems for ...

2-Axis and 3-Axis Gantries

Reliable handling technology for high cycle times and safe processes Automation makes packing and handling ...

In-Line and End-of-Line Testing

The implementation of automated End-of-Line (EOL) and In-Line testing systems enables companies to make their ...