Technical Laminates

Manufacturing Solutions for Technical Laminates, PCBs & Multilayers

We provide fully customized, automated manufacturing technologies to produce technical laminates, printed circuit boards (PCBs), and multilayers with maximum efficiency and precision.

Demands in electronics manufacturing are constantly rising. Manufacturers of technical laminates—used, for example, in PCB production—face the challenge of producing highly complex, multilayered products with the finest structures in a cost-effective and reproducible way. With automated manufacturing solutions from Rotte, you can overcome these challenges with ease. Our modular systems ensure maximum precision, process reliability, and efficiency—whether producing single-sided, double-sided PCBs, multilayers, or technical laminates for other applications.

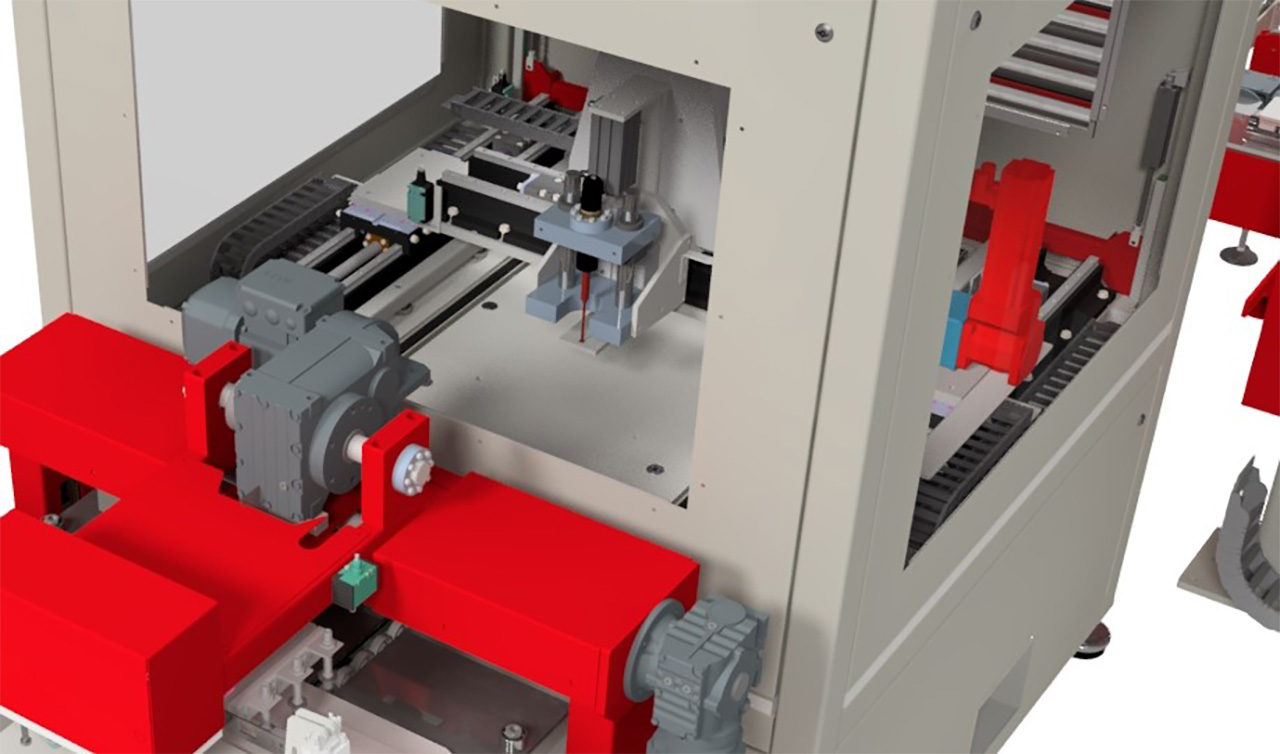

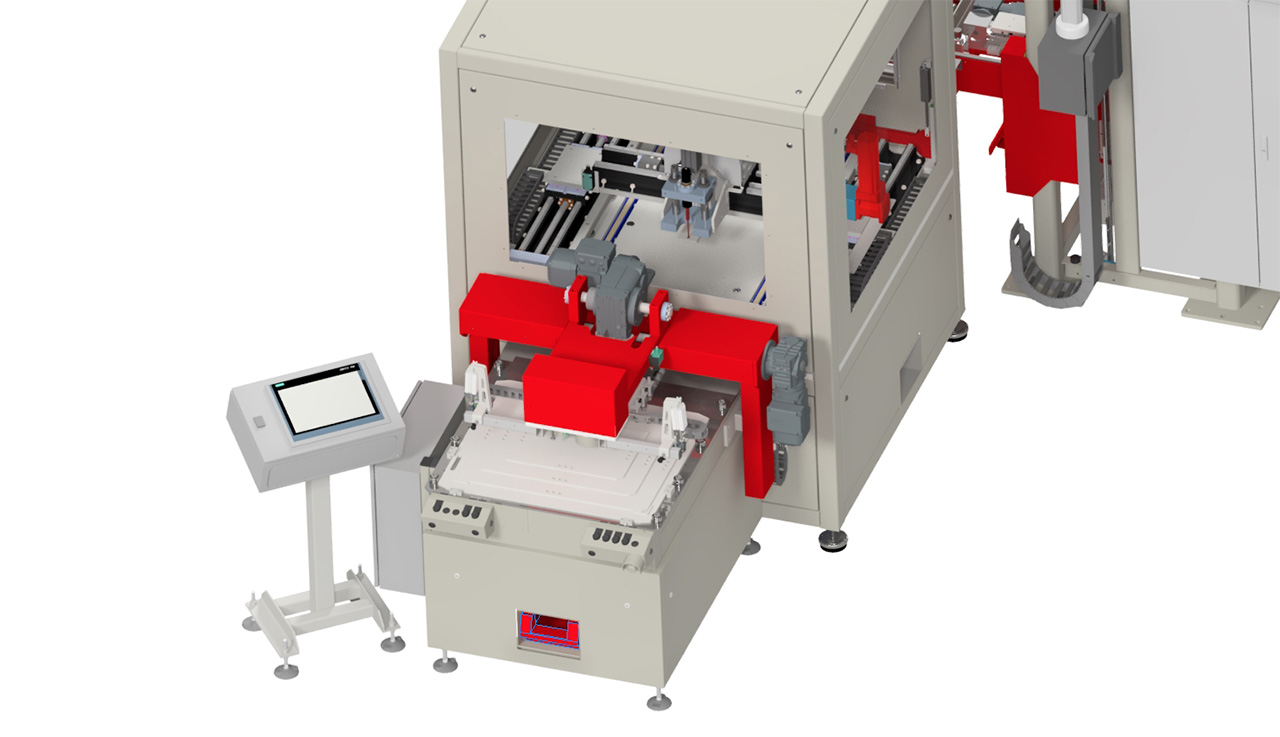

Our customer-specific systems enable full or semi-automated processing of sensitive materials—from handling, laminating, and pressing of base carriers to component placement, final trimming, and optical inspection of conductor traces. We rely on the latest technologies such as robot-assisted processing units, advanced vision systems, intelligent control systems, and real-time monitoring sensors to ensure consistent high quality and minimize waste.

Your contact person

Daniel Bürgermeister

Technical sales & project planning

Precision Manufacturing, Reliable Inspection – Increased Efficiency Through Automation

Manual processing is too error-prone and not scalable enough, especially in PCB and laminate production. Our automation solutions make it possible to position materials precisely, press them reliably and process them with repeat accuracy. This shortens cycle times, avoids quality fluctuations and reduces production costs. Thanks to the use of flexible production modules, different formats, layer structures and materials can be processed without any problems. This makes Rotte systems ideal for series production as well as for product lines with many variants – regardless of whether the end product is a printed circuit board, a carrier board or a structural component with a low-friction surface.

Machines and Systems for PCB Production and More

Our systems combine high-precision drives, adaptive control technology, and powerful sensors. Depending on the application, they include automatic layer feed systems, press stations with controlled pressure and temperature profiles, optical inspection units, and automated stacking and sorting units. Control is handled via modern HMIs with intuitive user interfaces, while all relevant process data can be centrally monitored and documented. This results in high-quality components for all applications where technical laminates and multilayers with tight tolerances are required.

Integration into existing production environments is easily achievable thanks to open interfaces and flexible system concepts. Whether you need a single processing station or a complete line solution—we adapt every component to your specific requirements.

Versatile Applications in Multilayer Manufacturing

Our systems are designed for a variety of tasks within the production of multilayers with different thicknesses and various mechanical properties. They enable the production and processing of FR4 standard laminates just as reliably as the processing of flexible and rigid-flexible PCBs and thermoplastic organic sheets as well as composite materials. Our solutions offer a high degree of precision and process reliability, particularly in the production of complex, multilayer layouts with a high number of layers.

All essential process steps—from automated layer build-up to precise alignment, pressing, and tempering—can be seamlessly integrated. Inline and end-of-line quality inspections ensure reliable error detection and continuous process monitoring. After manufacturing, our systems can also sort, package, and label finished laminates and PCBs—ensuring an uninterrupted and efficient production flow.

Choosing an automated production solution from Rotte offers both technical and strategic advantages: reproducible processes significantly improve product quality, while precise control systems reduce scrap rates. Relieving your staff of physically demanding or repetitive tasks enhances ergonomics and employee satisfaction. Our modular systems also provide the flexibility and scalability needed to integrate new formats quickly and handle increasing volumes efficiently. Increased output with lower quality-related costs ensures a fast return on investment.

Tailored Solutions – From Concept to Commissioning

Rotte provides custom solutions for your production needs—not just in PCB manufacturing. In close collaboration with your team, we analyze your processes, identify automation potential, and develop a well-thought-out concept tailored to your products, infrastructure, and objectives.

Following development and production, we integrate the solution into your manufacturing line—including all necessary interfaces. Our technicians provide comprehensive training for your team and remain available after commissioning with reliable service and a detailed maintenance concept—to ensure maximum availability and long-term success.

If you’re looking to modernize production, streamline processes, and maximize quality, Rotte is your partner for every automation-capable step in your operation. Talk to us today!

Our products

Lay-up station

Smart material supply for technical laminates and panels with Lay-up Stations from Rotte. In the ...

Flipping-Stations

Flipping material—without compromising quality or cycle time Whether for preparing lamination processes, two-sided processing, or ...

Automated De-Pinning

Rotte De-Pinners for technical laminates, panels, and more In the production of technical laminates, panels, ...

Breakdown Stations

Customized Breakdown Stations for your requirements Rotte designs tailored breakdown solutions precisely matched to your ...

Automated Storage Systems for Multi-Daylight Presses

Perfect handling starts with the right gripper In high-output production processes involving multi-daylight presses, efficient ...

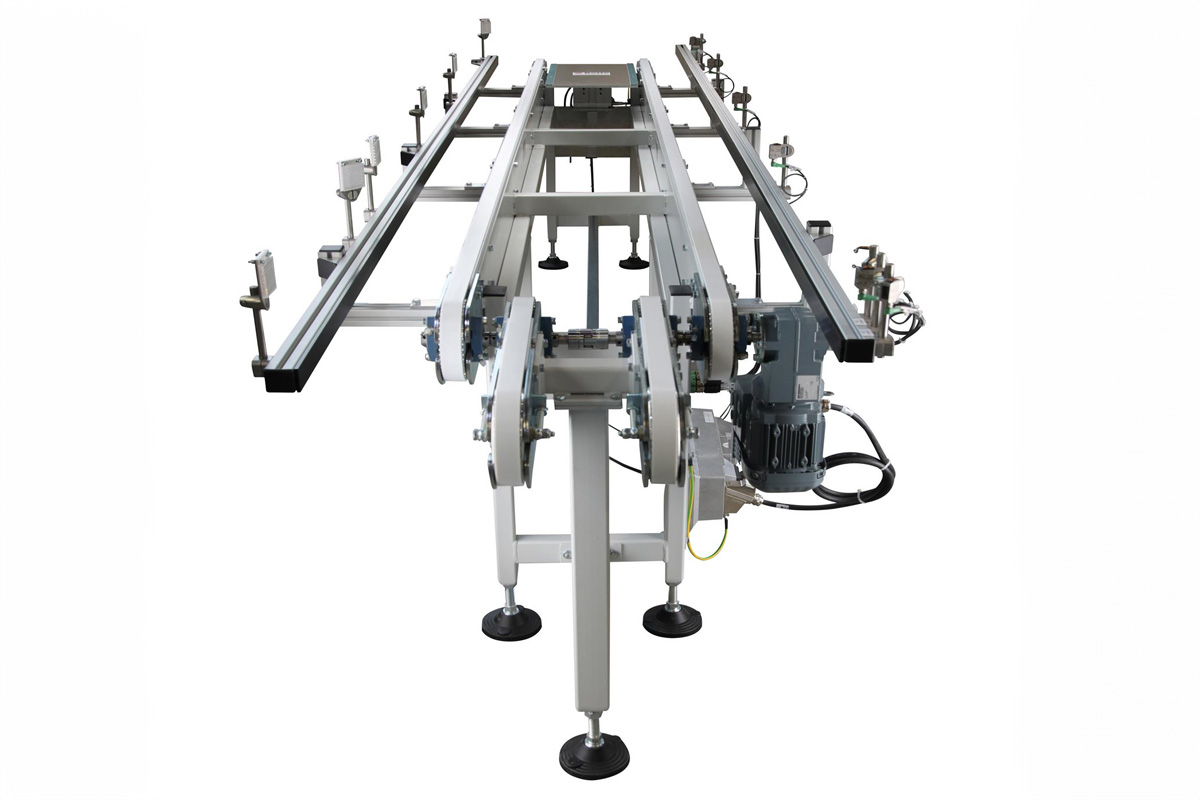

Belt Conveyors

Custom Conveyor Solutions for Your Production Efficient material flow is essential in modern production and ...

Loading and Stacking Robots

Smart Automation for Precise and Efficient Stacking In today’s industrial environments—with their complex production and ...

Picking Robots

Robotic Order Picking: Efficient Automation for Precise and Flexible Logistics with Customized Picking Robots In ...

Pick-and-Place Robots

Rethinking parts handling – efficient, error-free, automated Harness the full potential of Rotte’s robotics expertise ...

Modular Conveyor Technology with Roller Conveyors

Optimised material flow thanks to intelligent, adaptable conveyor solutions. An efficient material flow is key ...

One Company, Many Advantages

Ulrich Rotte Anlagenbau & Fördertechnik GmbH is your specialist in custom machinery. In addition to our innovative solutions in special-purpose machinery and automation technology, you also benefit from a wide range of customer and after-sales services:

Your Advantages at a Glance:

- Decades of experience in special-purpose machinery

- Extensive know-how across all areas of automation technology

- High expertise in the latest technologies and applications for Industry 4.0

- All services from a single source—from development and design to manufacturing, assembly, commissioning, and regular on-site maintenance

- Optional training of your machine operators, technicians, and supervisors at your facility

- Mechanical engineering made in Germany – we design and manufacture exclusively in Germany

- Personalized customer support – you will always have a qualified contact person available