Custom Handling Systems

Custom Handling Systems

Precision and efficiency in material flow are only possible with modern automation solutions. As production and logistics processes become increasingly complex, automation plays a vital role in maintaining competitiveness. Companies face the challenge of moving components, workpieces, and packaging units as time- and cost-efficiently as possible. Handling systems are essential in achieving this, ensuring continuous material flow while minimizing errors and downtime.

Your contact person

Daniel Bürgermeister

Technical sales & project planning

Customer-Specific Handling Technology for the Highest Demands

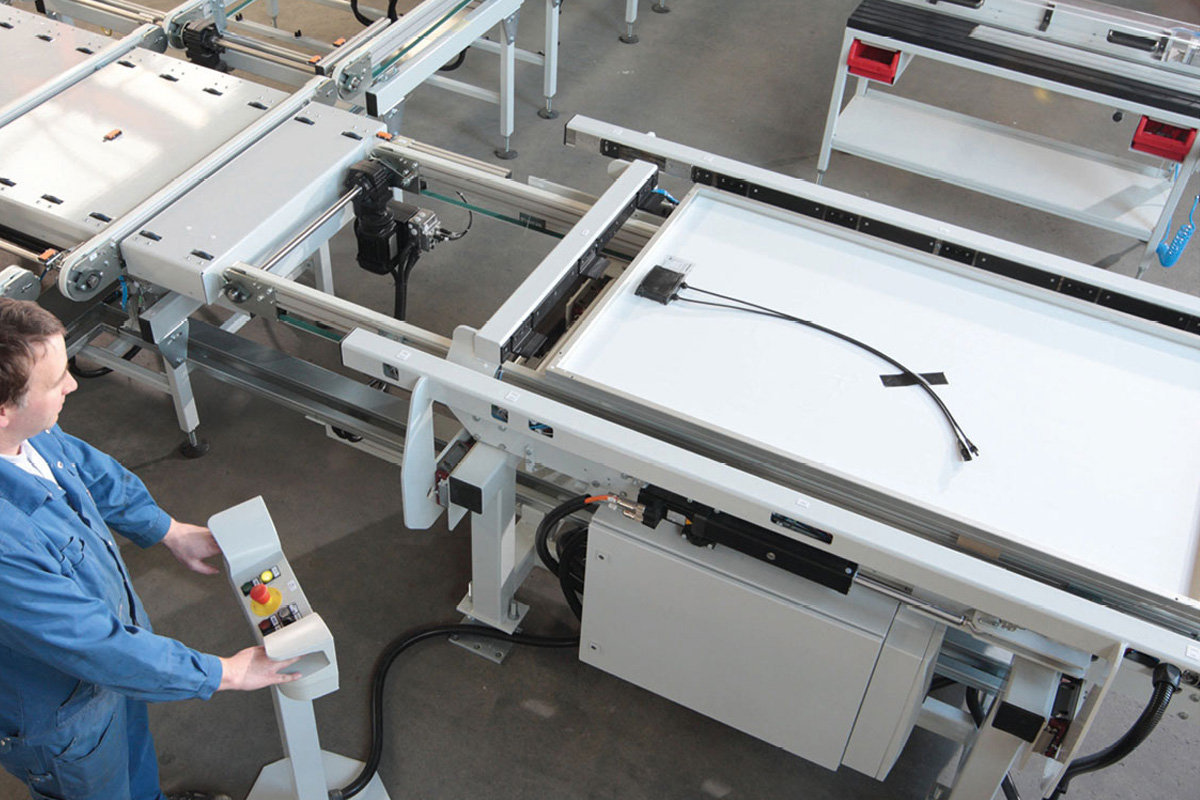

Rotte develops custom handling solutions precisely tailored to your production requirements. Whether it’s positioning individual workpieces and components, automatically stacking and unstacking parts, or feeding and sorting materials—our systems ensure reliable handling across a wide range of processes. With our deep experience in special-purpose machinery and automation technology, we seamlessly and purposefully integrate your customized handling system into existing production and logistics operations—ensuring long-term performance optimization.

Our solutions cover a wide range of applications—from separating and precisely positioning small parts, to stacking and unstacking pallets, to safely conveying, rotating, and orienting products in assembly lines. Thanks to a modular design, our systems can be expanded later or adapted to new production requirements.

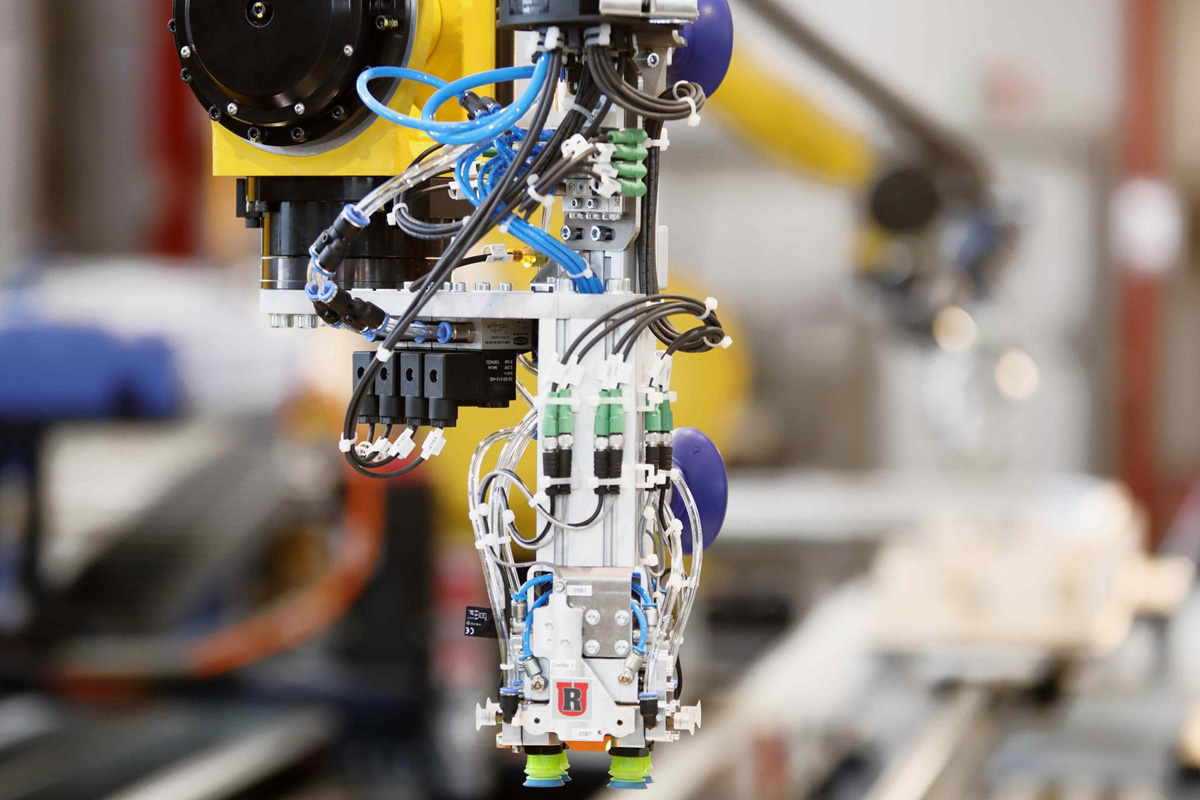

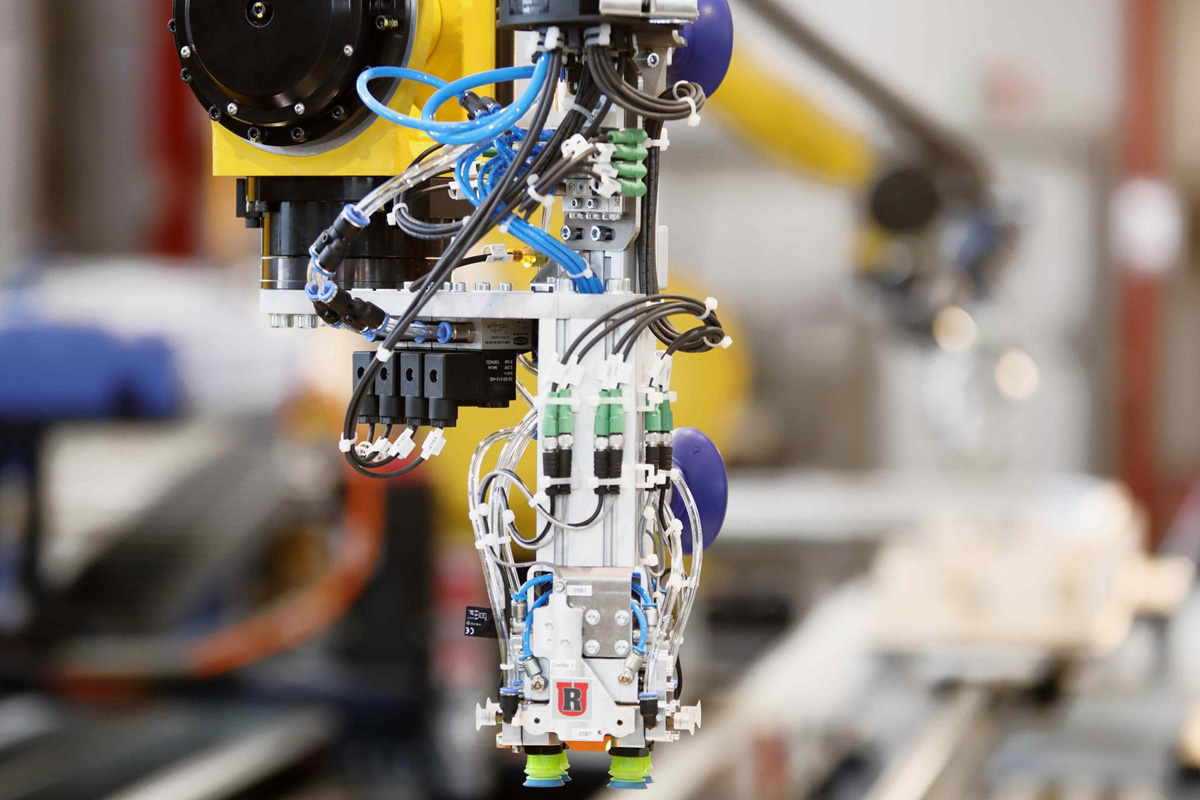

A critical element of our handling systems is the right gripping and positioning technology. Depending on your requirements, we use mechanical, pneumatic, or magnetic grippers tailored to your workpiece. Mechanical grippers provide a robust solution for heavy or irregularly shaped parts, while vacuum or magnetic grippers handle delicate products with care. We offer a wide portfolio of reliable and flexible technologies—each of which can be customized to meet your specific needs.

Our handling technology expertise enables:

- Separation and positioning of various objects

- Accurate stacking and unstacking of parts or pallets

- Sorting and staging for downstream processes with variable cycle times

- Conveying, rotating, and flipping both small parts and heavy loads

- Assembly handling for production processes across virtually all industries

- Flexible coordination with robots and other production equipment

- Low-maintenance drive technology and mechanical components

- Mechanical durability and long service life

- User-friendly operation via proven control systems

- Improved ergonomics for your employees

Automation for Maximum Precision and Process Reliability

Rotte handling systems combine precision mechanics, intelligent control systems, and state-of-the-art sensor technology. With minimal axis tolerances and highly sensitive sensors, parts can be positioned with millimeter accuracy, enabling smooth downstream processes.

We integrate various axis configurations into our systems depending on the application. Advanced linear drives enable fast and accurate material movement in one direction, while rotating axes ensure that parts are oriented optimally for further processing. In more complex applications, axis portals or industrial robots with advanced camera systems provide maximum flexibility and motion range.

All our special-purpose systems can be integrated with higher-level ERP or MES systems for real-time monitoring and material flow optimization.

Applications of Our Handling Systems

Rotte handling systems are indispensable across numerous industries and production areas.

In the automotive industry, they are used for precise handling of body components, battery modules, or engine parts. In mechanical engineering, they manage the movement of heavy castings or metal plates. The packaging industry relies on our systems for automated palletizing, depalletizing, and carton filling.

In the pharmaceutical and food industries, automated handling ensures hygienic handling of sensitive products and consistent quality in packaging and downstream processes. The electronics sector uses our handling solutions to feed and assemble delicate electrical components—where maximum accuracy is critical.

Thanks to their modular structure, our systems can always be expanded or adapted to new requirements.

Maximum Efficiency with Intelligent Handling Systems

Our handling systems are designed to sustainably improve efficiency and cost-effectiveness in your production. By implementing tailored solutions, human error and manual corrections can be significantly reduced—leading to higher productivity and lower defect rates.

Another major benefit is precise process control, enabled by intelligent automation and sensor technology. Our systems offer high repeat accuracy and exact part positioning, maintaining consistent product quality.

We also place great importance on durability and ease of maintenance. Sturdy construction, premium materials, and thoughtful engineering ensure reliable performance with minimal upkeep—ultimately reducing operating costs in the long run.

Comprehensive Consultation and Custom Solutions from Rotte

From the initial consultation to design, engineering, integration, and commissioning, we’re with you every step of the way. We also provide ongoing service and maintenance to ensure your systems run smoothly.

Handling systems from Rotte ensure precise material flow, reduce manual processes, and elevate production efficiency to a new level. If you’re ready to increase profitability and competitiveness with a new handling system—or benefit from our expertise in special-purpose machine construction—we’re here for you. Contact us today for a personalized consultation!

One Company, Many Advantages

Ulrich Rotte Anlagenbau & Fördertechnik GmbH is your specialist in custom machinery. In addition to our innovative solutions in special-purpose machinery and automation technology, you also benefit from a wide range of customer and after-sales services:

Your Advantages at a Glance:

- Decades of experience in special-purpose machinery

- Extensive know-how across all areas of automation technology

- High expertise in the latest technologies and applications for Industry 4.0

- All services from a single source—from development and design to manufacturing, assembly, commissioning, and regular on-site maintenance

- Optional training of your machine operators, technicians, and supervisors at your facility

- Mechanical engineering made in Germany – we design and manufacture exclusively in Germany

- Personalized customer support – you will always have a qualified contact person available

Our products

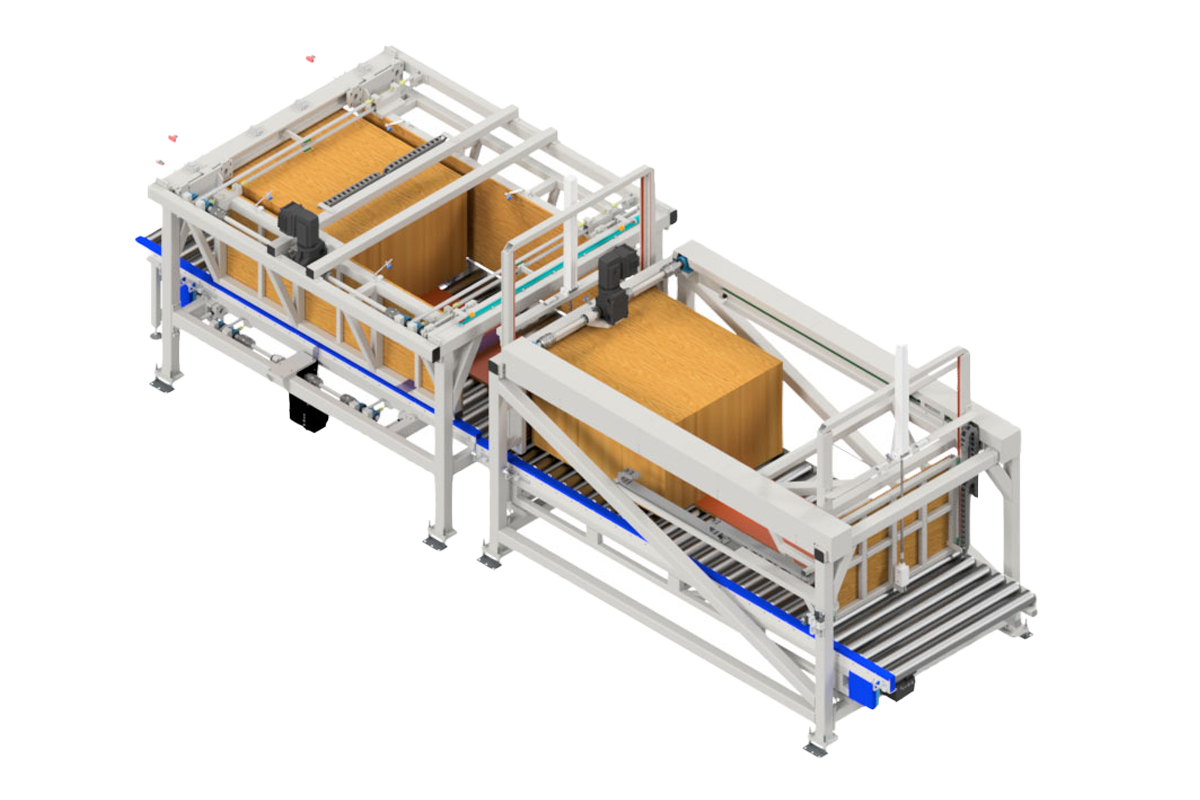

Automatic Pallet Magazine

Effortless Stacking and Destacking with Variable Capacity Efficient solutions for the automatic stacking and separation ...

Drum Turner

When Everything Revolves Around Your Workpieces Turners for panels of all material types: In many ...

Robotic Grippers

Perfect handling starts with the right gripper We equip your robots, cobots, and robotic cells ...

Alignment Stations

Precision in flow – the right solution for every position Rotte alignment stations ensure exact ...

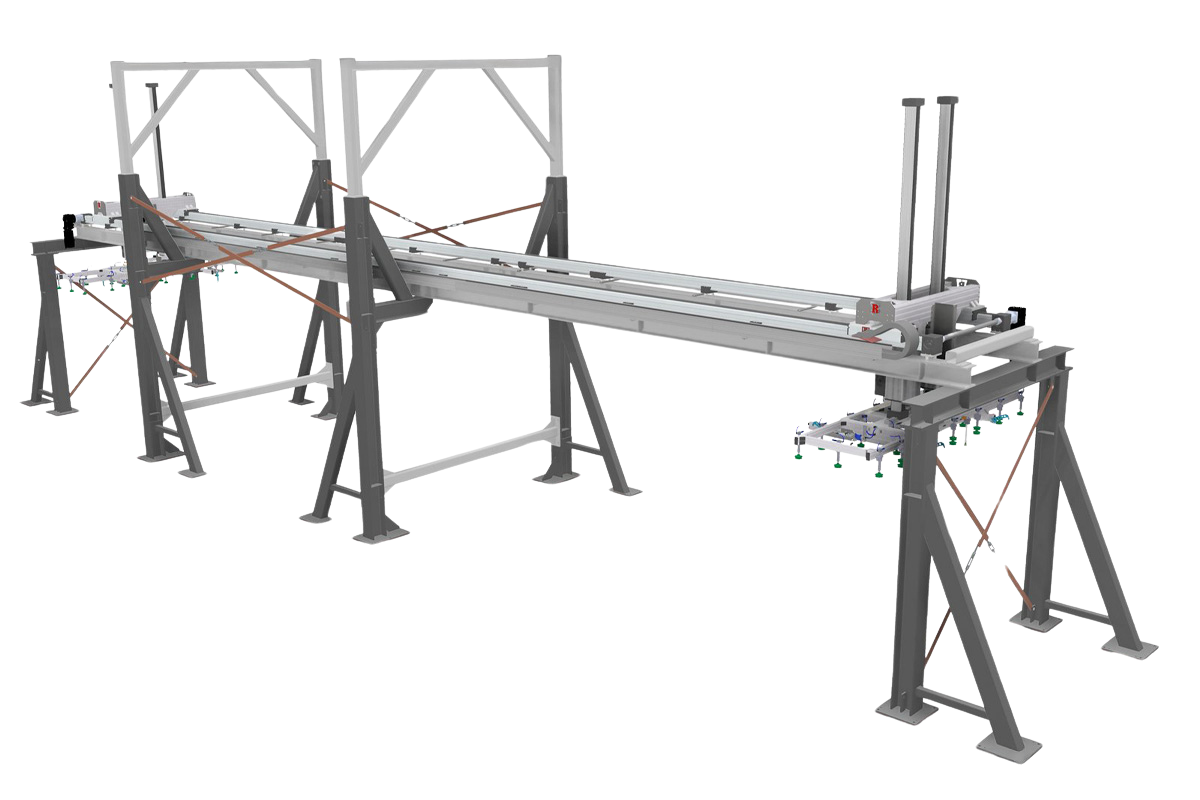

2-Axis and 3-Axis Gantries

Reliable handling technology for high cycle times and safe processes Automation makes packing and handling ...