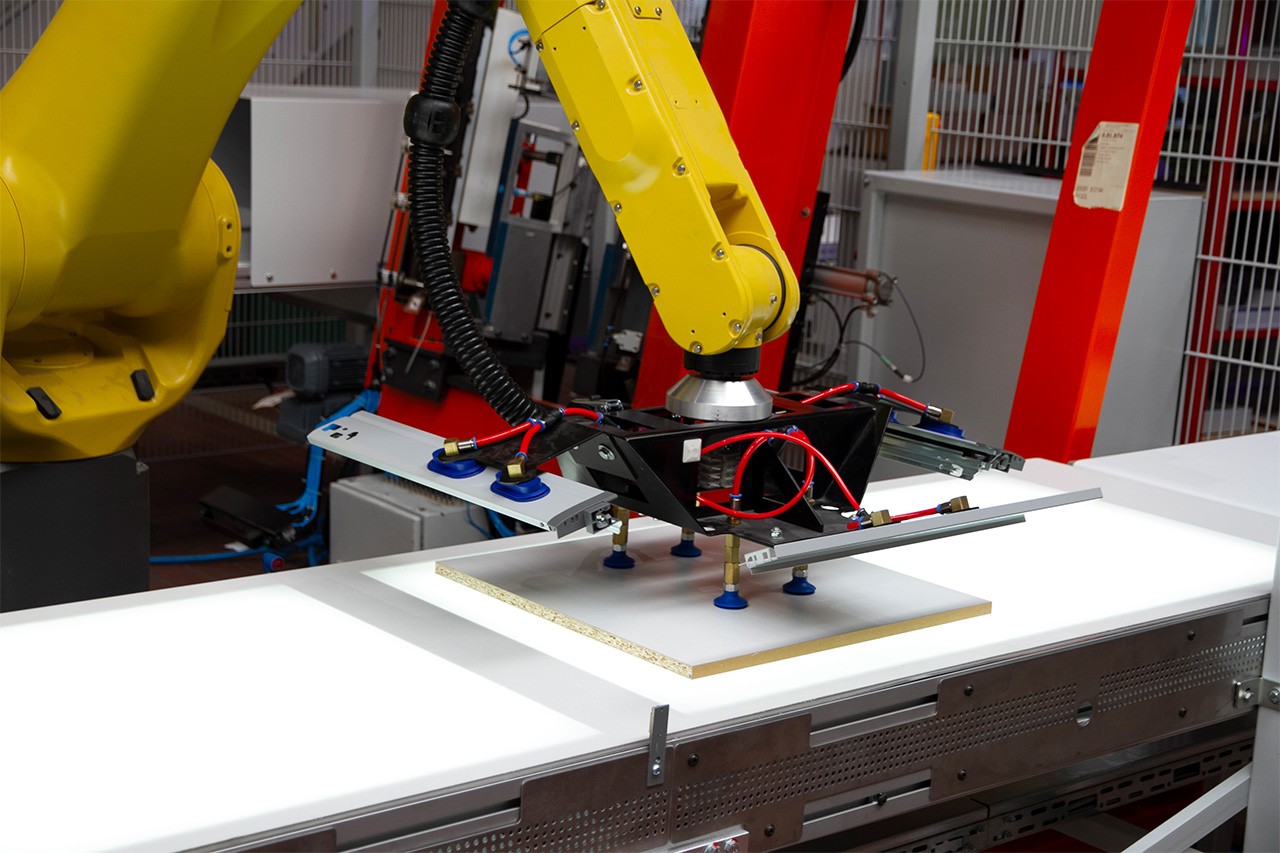

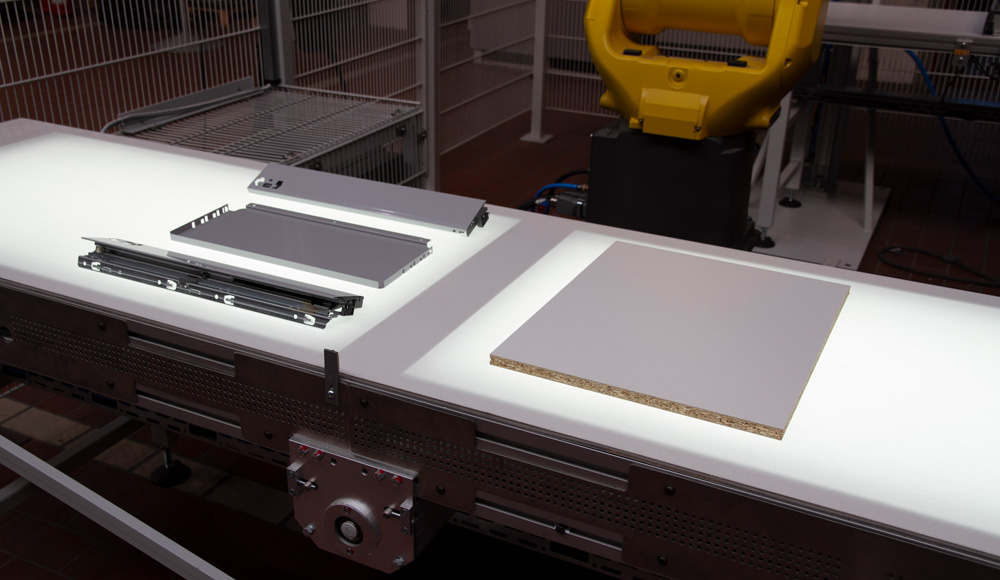

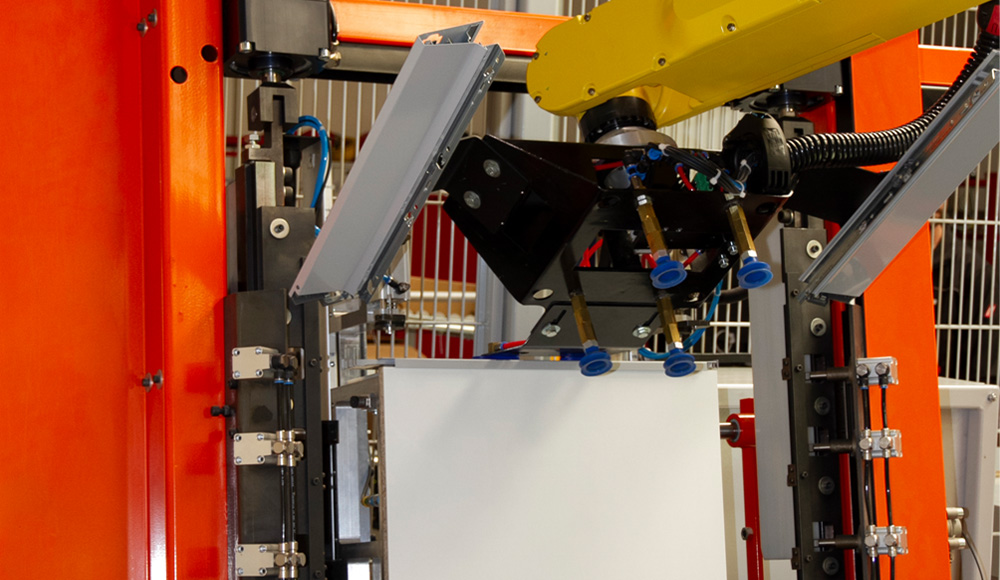

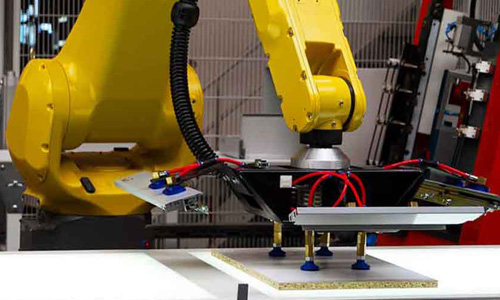

Robotic solutions for drawer assembly in the furniture industry

In furniture manufacturing, precision is key—especially in drawer assembly. As a recurring and often time-intensive step in production, it significantly impacts cycle time, product quality, and ergonomics. With Rotte’s automation solutions for drawer assembly, you can permanently optimize this process: Our systems assemble drawers quickly, with precise positioning and repeatable accuracy—adapted to your specific furniture systems. This not only increases output but also reduces error rates and noticeably eases the workload of your employees.