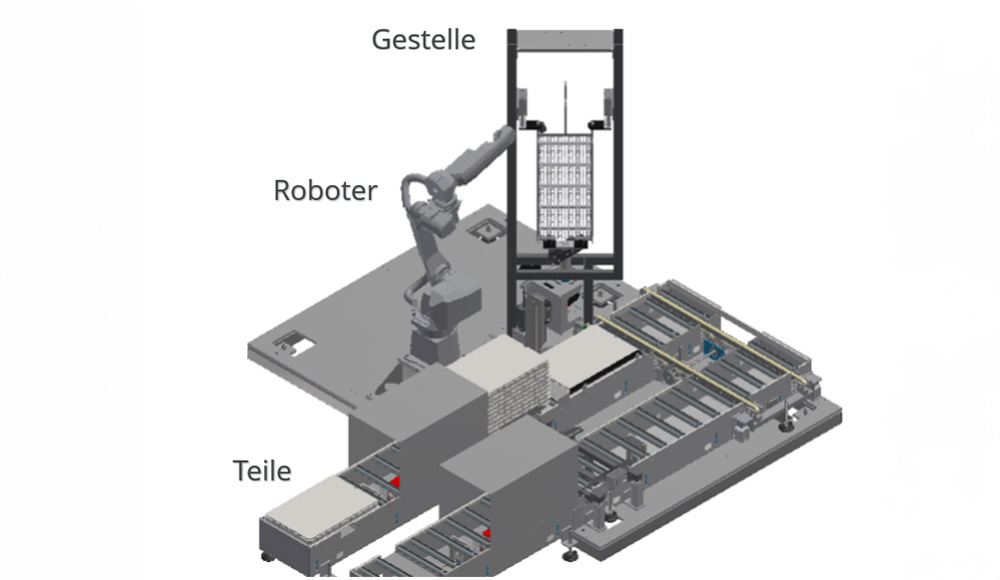

Efficient, safe, precise: Automated rack loading with system

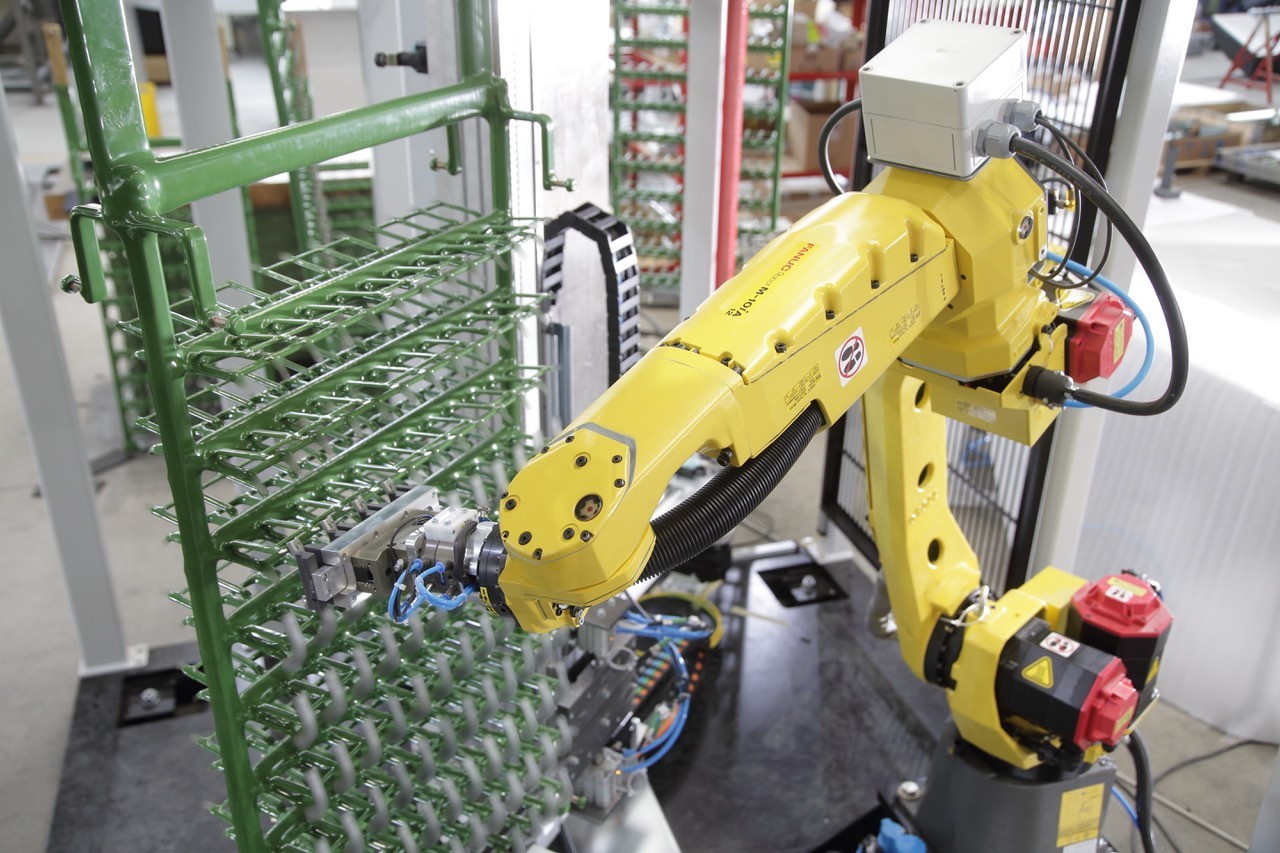

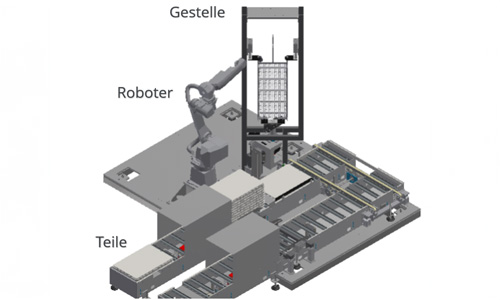

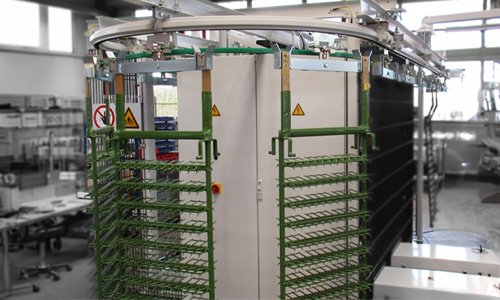

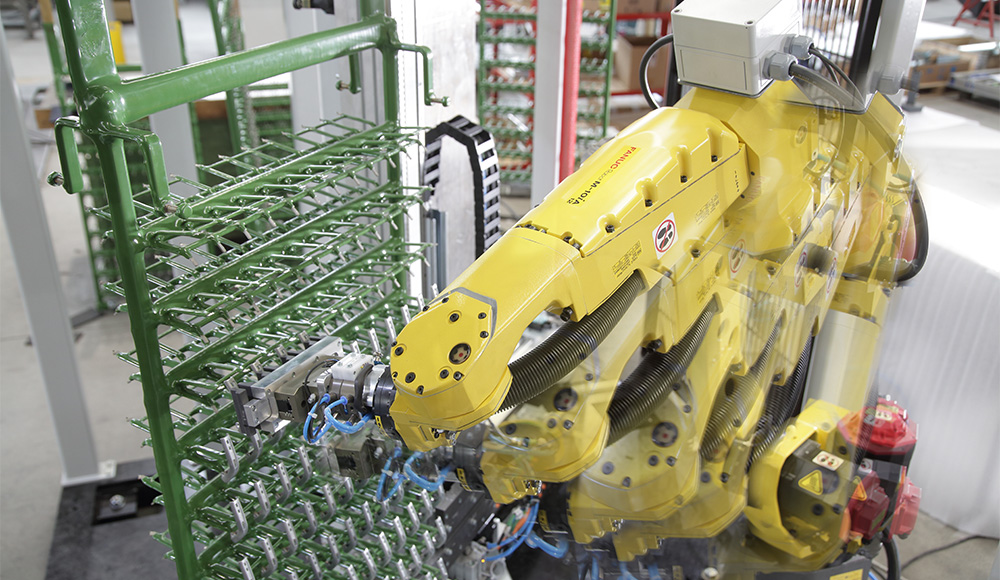

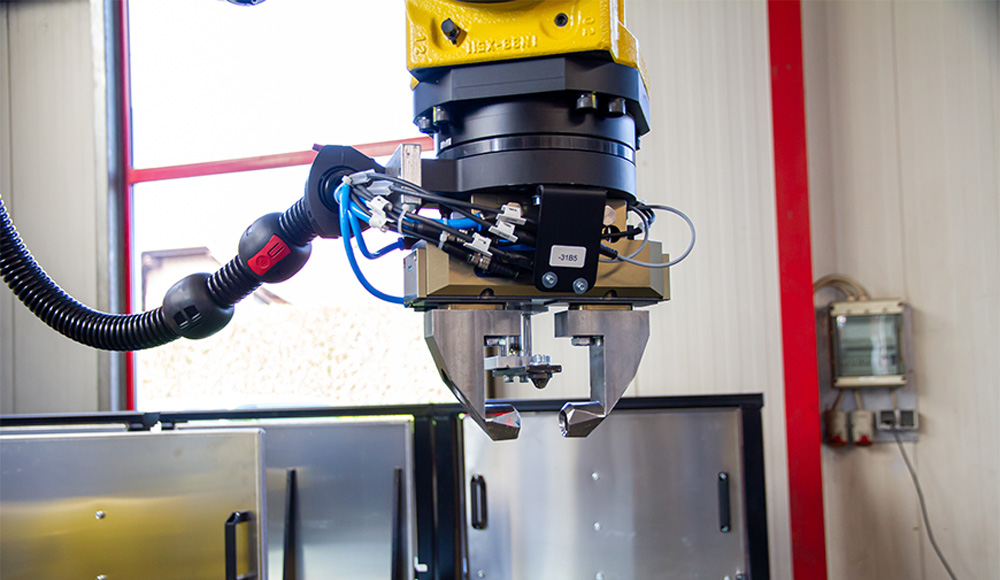

Whether powder-coated components, painted workpieces, or heat-treated parts—many industrial processes require precise, fast, and uniform rack loading. This is where Rotte comes in: We develop automated rack loading systems tailored to your production requirements. Our robotic solutions load racks with repeatable accuracy and precise positioning—for uniform part suspension, ideal process conditions, and consistent quality standards. Discover how automated rack loading can make your production more efficient, safer, and more economical.