Chemical Industry

Custom Systems for the Chemical Industry

Plant Engineering and Special Solutions for Demanding Processes—from Rubber Processing to Plastics Manufacturing

The chemical industry is one of the most diverse and demanding sectors—high quality standards, sensitive materials, and safety-critical processes define its working environment. With decades of experience in custom machine engineering and process automation, Rotte is your trusted partner for tailored automation solutions in the chemical industry. We provide powerful plant concepts focused on efficiency, safety, and diverse procedures.

As a specialist in customized systems, we design turnkey facilities for conveying, assembling, and manufacturing that support your processes from material handling through production to storage and logistics. Our experts guide you from the initial idea and planning phase through to the ready-to-run implementation of your custom solution. As a general contractor, our clear focus is on delivering the highest quality through maximum system availability, process stability, and individually tailored designs.

Contact us today and benefit from innovative chemical systems that boost your productivity and give you a competitive edge in the global chemical industry!

Your contact person

Daniel Bürgermeister

Technical sales & project planning

Engineering for the Rubber Industry – High-Performance, Robust, and Fully Customizable

In rubber processing, one thing matters most: precise material handling paired with exceptional system durability and reliability. Whether working with natural or synthetic rubber, our custom-engineered systems for this economically critical raw material industry enable efficient, OEM-compatible production of rubber sheets and other feedstocks for the tire industry, sealing technology, or technical molded parts.

Our systems cover the entire process chain—from bale to cooling to further processing.

Each of our systems for the chemical industry is designed for maximum operational safety, easy maintenance, and long service life—and of course customized to meet the specific demands of various manufacturing methods.

Our technology includes:

- Bale Cutters: Our automated roll-cutting method ensures clean and process-safe trimming of rubber bales—even with high volumes and varying material hardness. During customization and construction, we focus on heavy-duty performance and seamless integration into existing processes.

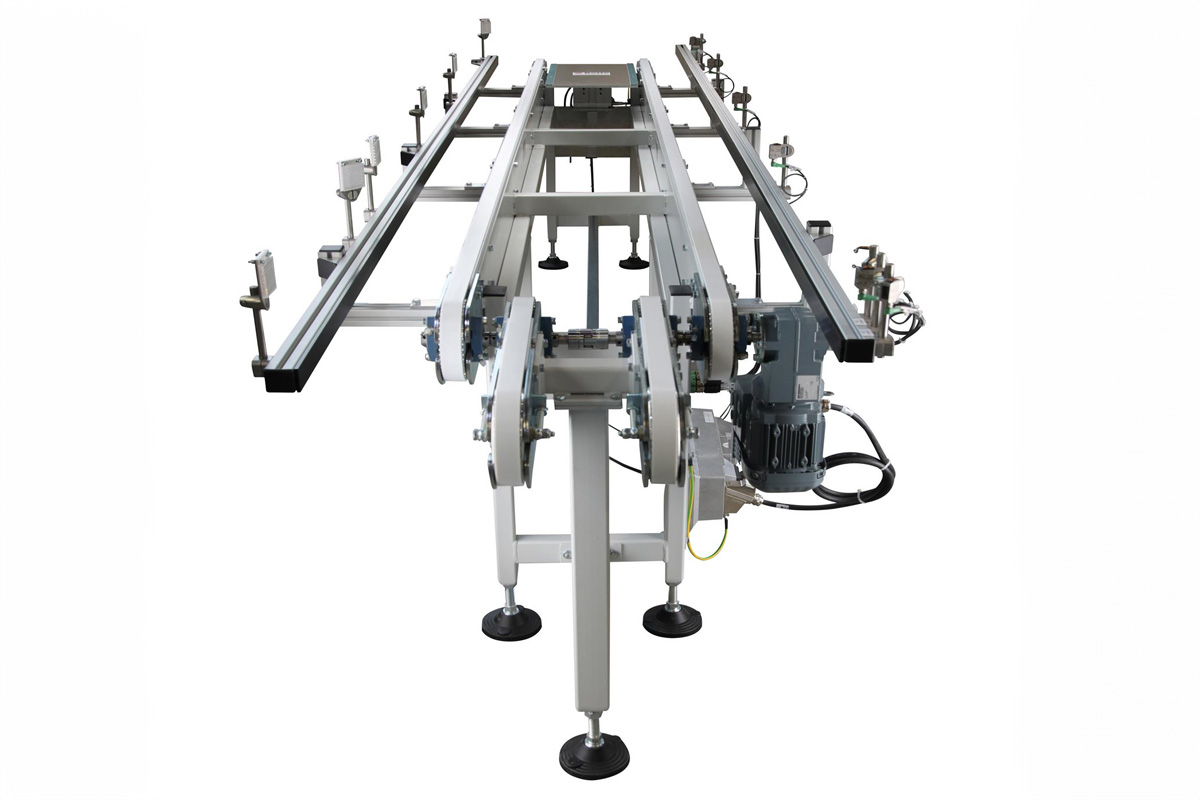

- Weighing and Feeding Conveyors: For precise dosing and delivery of rubber sheets, we use tailored conveyor belts with integrated weighing systems that operate reliably even under demanding conditions.

- Batch Feeders: Our specially developed batch feeder processes up to three rubber sheets at once—with maximum cutting precision and high cycle performance. This not only increases throughput but also improves downstream process quality.

- Sheet Cooling Systems: To optimally prepare rubber sheets for further processing, we offer cooling systems in various configurations, including cantilever and linear types, customized to your space and cycle time requirements.

- Storage and Transport Systems for Green Tires: For the continued processing of raw tires, we provide intelligent conveying and buffering systems that ensure gentle and efficient handling of sensitive products.

Tailor-Made Systems for the Plastics Industry

Whether manufacturing technical plastic parts, films, or complex assemblies—Rotte supports its customers throughout the entire value chain with custom-engineered solutions for the plastics industry. Our systems are designed to handle high volumes reliably, reduce manual tasks, and measurably improve process quality.

Our solutions cover core areas of plastic processing—from cutting and stacking to joining, measuring, and inspection.

All of our systems for the plastics industry are robust, low-maintenance, and have proven themselves in numerous custom variations under continuous industrial operation. They set new benchmarks in custom machine and plant engineering for maximum process reliability, efficiency, and future readiness.

Our solutions cover core areas of plastic processing:

- Automated Punching of Molded Parts: For process-reliable drilling, slotting, or integration of functional elements into plastic components, we develop fully automated punching systems tailored to your geometries and tolerance requirements. These systems offer high processing speeds, precise positioning, and integrated quality assurance.

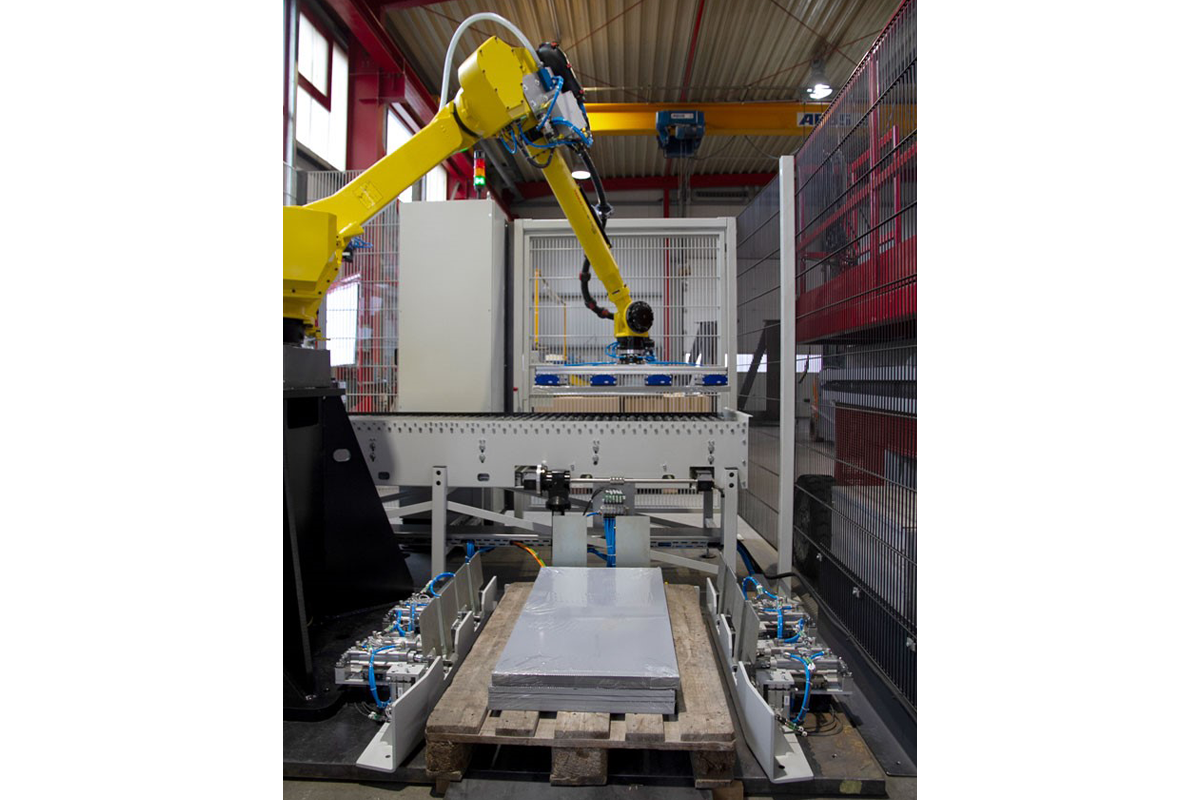

- Stacking Systems for Film Sheets: In processing thin plastic and composite films, accurate handling and stacking are essential. Our automatic stacking systems enable continuous processing and clean stacking—even at high cycle rates and with delicate materials. These modular systems integrate easily into existing cutting or packaging lines.

- Joining Systems with Force-Displacement Monitoring: For reliable joining of plastic components, we offer automated solutions with integrated force-displacement measurement. These systems document and control every joining process—such as thermal joining, pressing, or welding—and ensure complete traceability for each part.

- Measurement Automation: To reliably check the dimensional accuracy of your plastic parts, we also automate your measurement processes. Whether 2D/3D measurement, camera-based positioning, or tactile systems—our equipment handles component alignment, orientation, and transfer to the measurement station fully automatically, ensuring consistent inspection conditions, shorter cycle times, reduced staffing needs, and higher data quality.

Rotte – Your Partner for High-End Process Automation in the Chemical Industry

When you partner with Rotte, you gain an experienced expert who thoroughly understands your processes. Our interdisciplinary team of engineers, designers, and automation specialists develops solutions that are not only technically advanced but also economically sustainable in the long term.

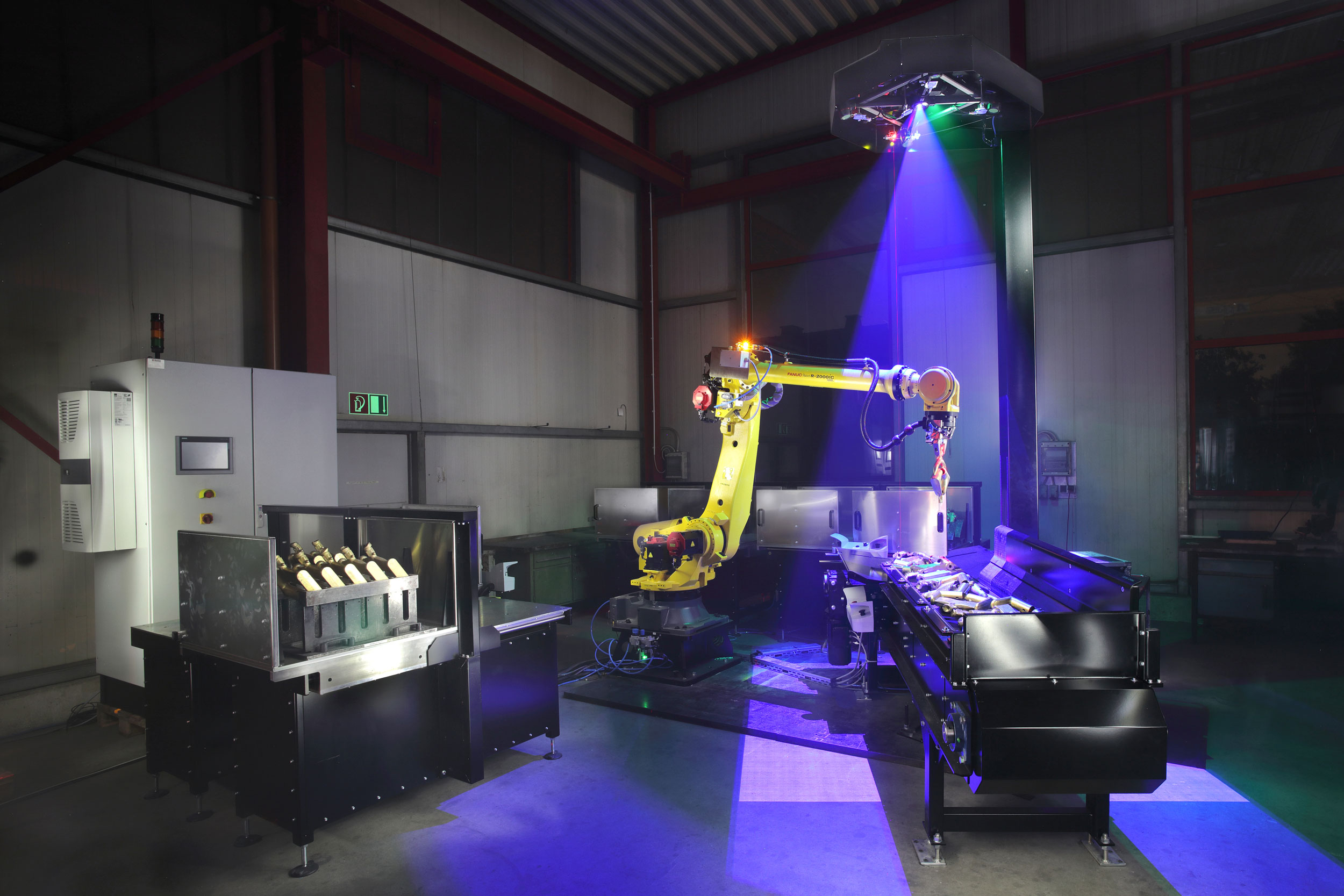

Thanks to our expertise in machine vision, robotics, intelligent control systems, and material handling, we offer complex, fully integrated special machines that help you build safe, efficient, and future-proof production systems.

One Company, Many Advantages

Ulrich Rotte Anlagenbau & Fördertechnik GmbH is your specialist in custom machinery. In addition to our innovative solutions in special-purpose machinery and automation technology, you also benefit from a wide range of customer and after-sales services:

Your Advantages at a Glance:

- Decades of experience in special-purpose machinery

- Extensive know-how across all areas of automation technology

- High expertise in the latest technologies and applications for Industry 4.0

- All services from a single source—from development and design to manufacturing, assembly, commissioning, and regular on-site maintenance

- Optional training of your machine operators, technicians, and supervisors at your facility

- Mechanical engineering made in Germany – we design and manufacture exclusively in Germany

- Personalized customer support – you will always have a qualified contact person available

Our products

Bin Picking Cell CAMPGripX-1200

Precise and reliable Bin Picking In modern industrial production, every second counts. Companies are increasingly ...

Bag and Pouch Packaging Machine

Efficient and Flexible Packaging Solutions Rotte develops fully customized packaging machines for pre-made bags and ...

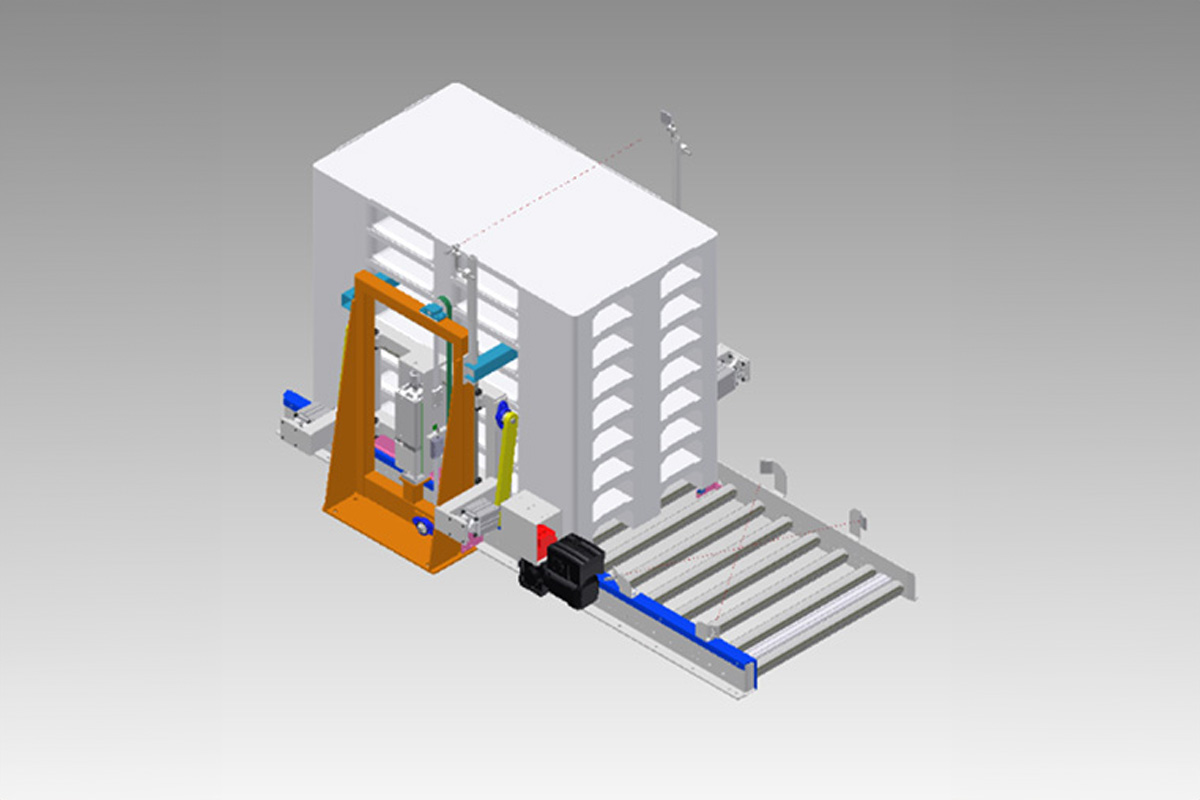

Automatic Pallet Magazine

Effortless Stacking and Destacking with Variable Capacity Efficient solutions for the automatic stacking and separation ...

Belt Conveyors

Custom Conveyor Solutions for Your Production Efficient material flow is essential in modern production and ...

Drum Turner

When Everything Revolves Around Your Workpieces Turners for panels of all material types: In many ...

Thermoforming Machine

For the industrial processing of sealing fleece, filters, and technical fiber materials, Rotte offers high-precision ...

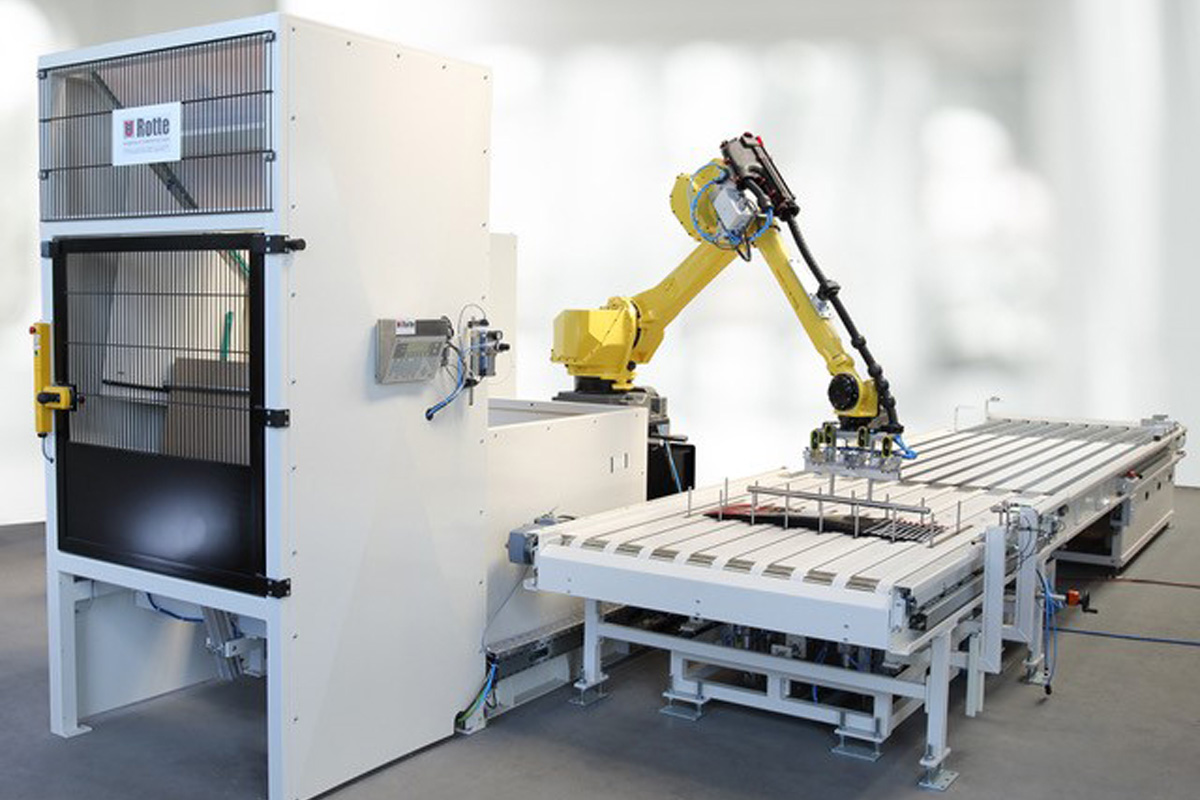

Loading and Stacking Robots

Smart Automation for Precise and Efficient Stacking In today’s industrial environments—with their complex production and ...

Automated Storage Systems for Multi-Daylight Presses

In high-output production processes involving multi-daylight presses, efficient storage and automation solutions are essential for ...

Heavy-Duty Roller Conveyors

Heavy-duty roller conveyors from Rotte are an optional yet integral component of our complete solutions ...

Picking Robots

Robotic Order Picking: Efficient Automation for Precise and Flexible Logistics with Customized Picking Robots In ...