Customized planning – perfectly aligned with your production

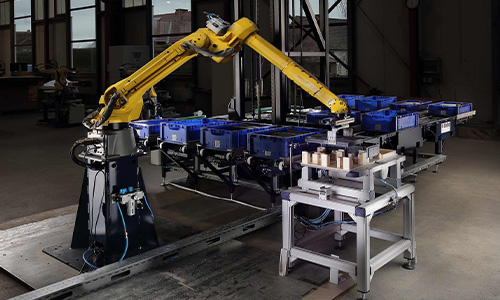

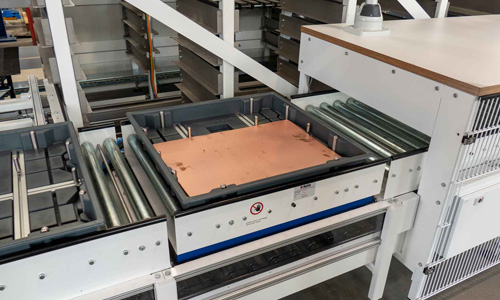

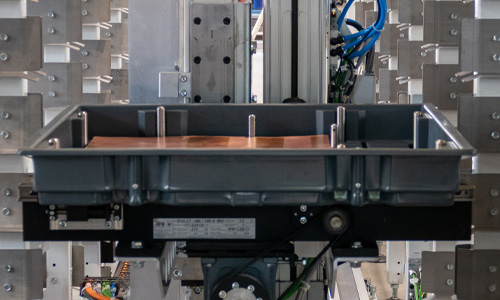

Every ROTTE solution is custom-engineered based on an in-depth analysis of your processes, material flows, and system interfaces. We consider every factor – from container geometry and takt times to autonomous material handover. The goal: fully automated, error-free storage in robot-powered systems that accelerate production, reduce manual workload, and prepare your facility for the future.