Process Technology for Industry

Custom Process and Production Technology

Process and production technology from Rotte supports companies across all industries in manufacturing, processing, and testing processes. With our diverse expertise in this field, we assist with all conceivable manufacturing, processing, and testing processes upon request. Enhance the quality of your products now, increase efficiency in your production, and effectively reduce costs!

While process technology optimizes the manufacturing flow, production technology ensures that this flow is implemented efficiently and precisely. This involves the development of machines, equipment, and systems that optimally support your manufacturing processes. Ulrich Rotte stands for production technology that is not off-the-shelf but is individually planned and implemented—tailored to your specific requirements and production goals.

Our solutions are characterized by high flexibility and scalability. Whether you operate complex production lines or need specialized custom machines—we develop technologies that seamlessly integrate into your production environment. We particularly focus on optimal ergonomics, short setup times, and easy maintenance to minimize your operating costs over the long term.

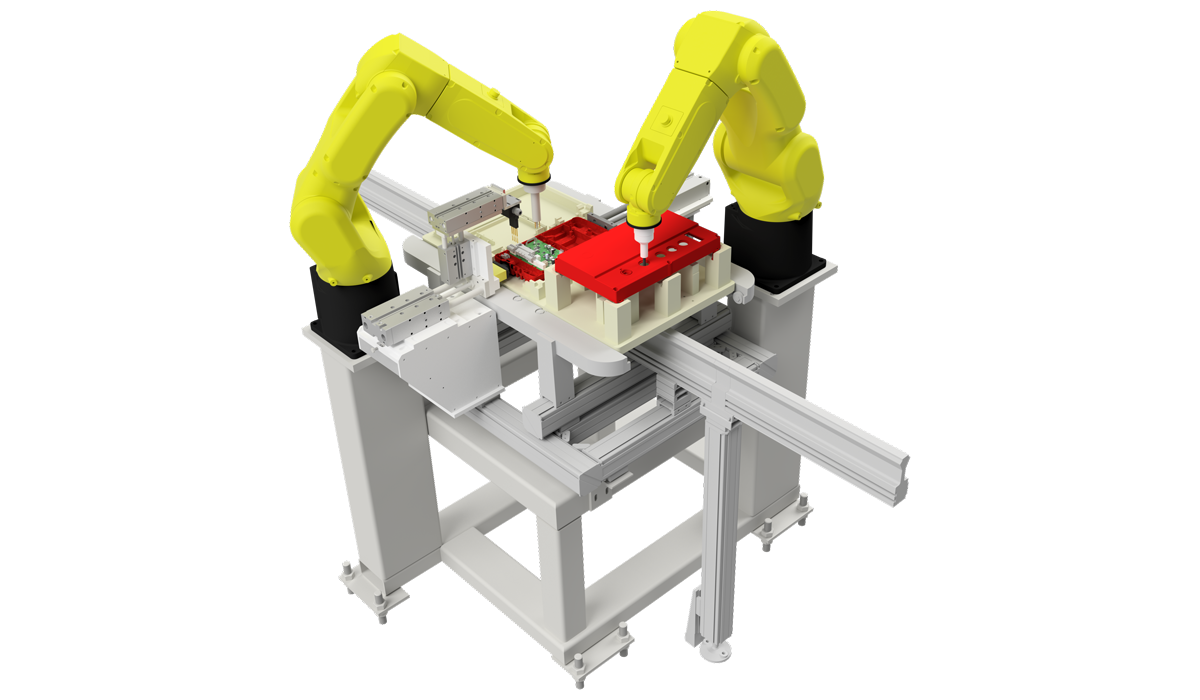

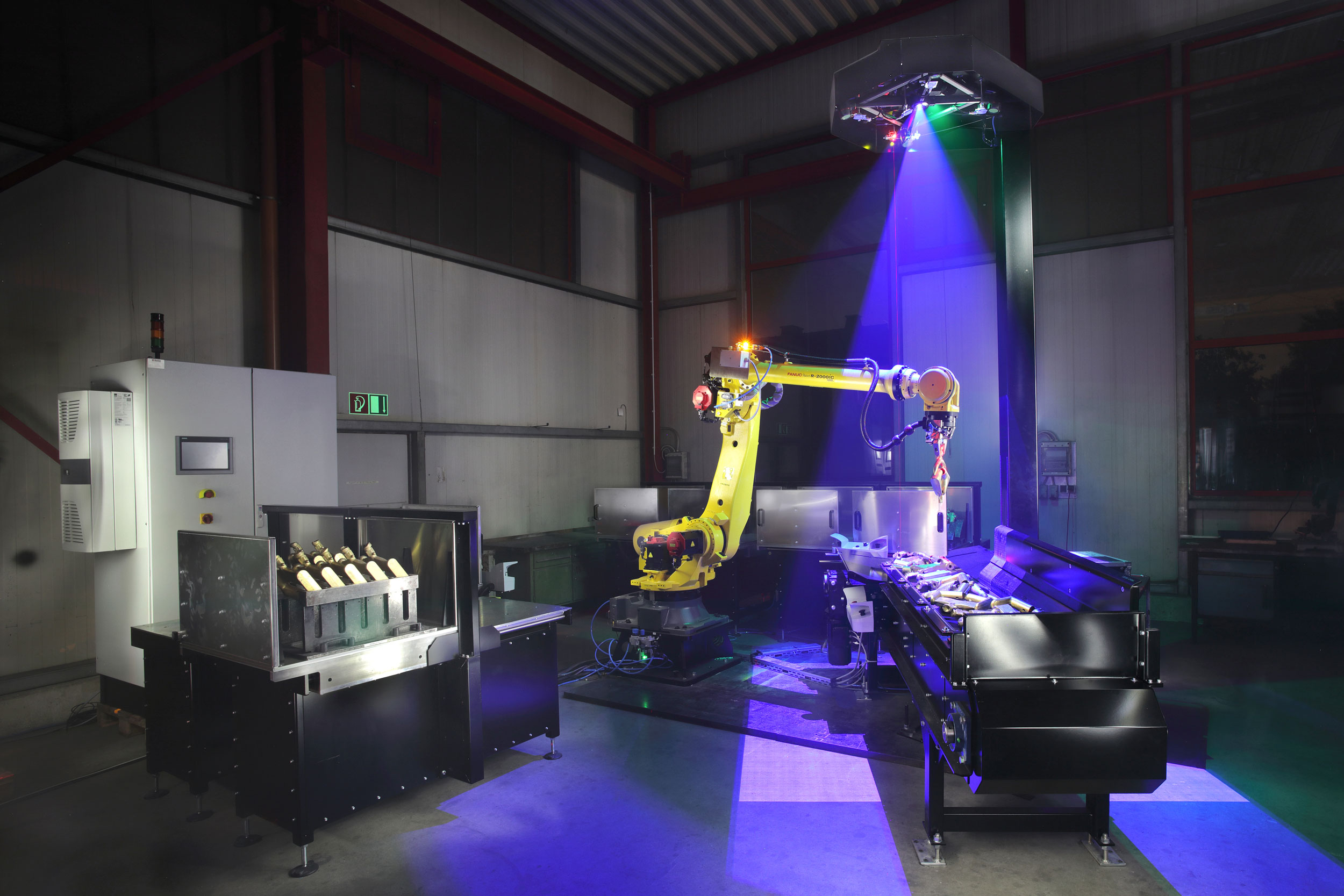

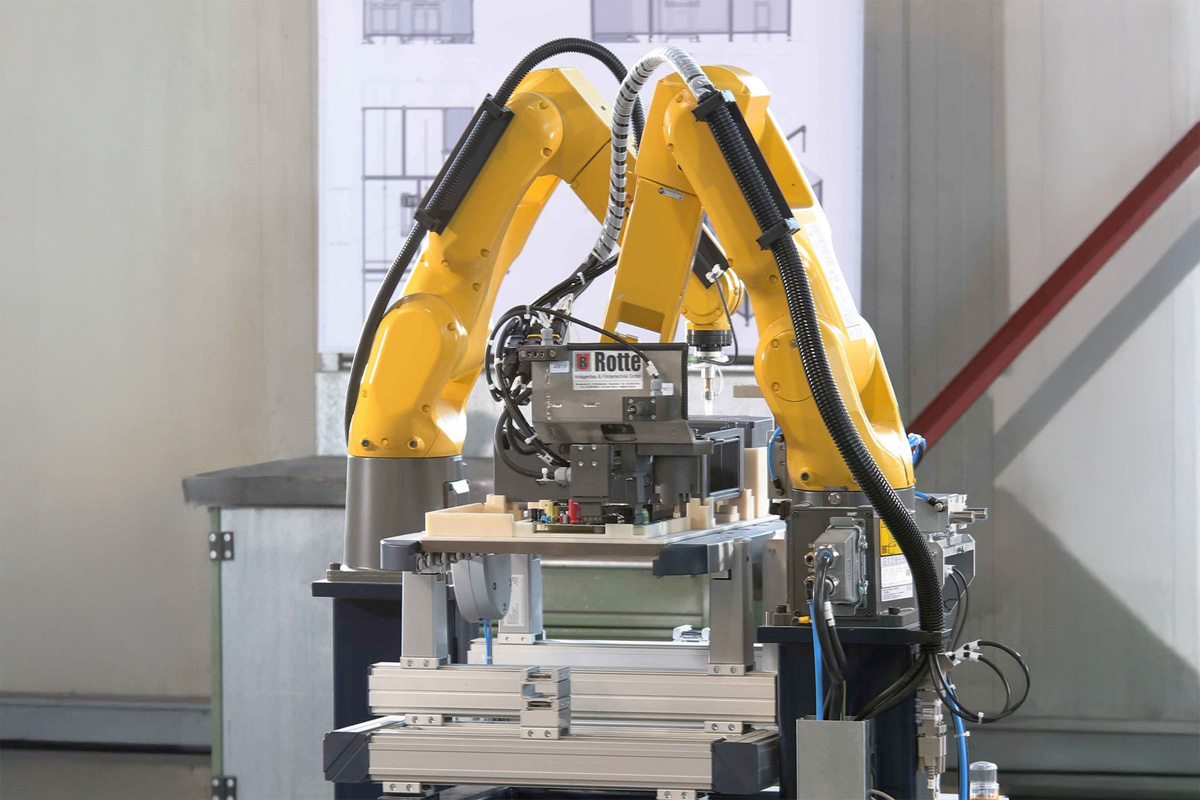

An important aspect of our production technology is the integration of automation solutions that not only increase efficiency but also ensure the quality of your products. By using robotics, sensor-based monitoring, and AI-driven control systems, we create facilities that intelligently adapt to changed production conditions, thus offering a decisive competitive advantage.

Your contact person

Daniel Bürgermeister

Technical sales & project planning

Testing the door control unit - optical and electronic

The Key to Optimized Processes – Your Custom Solution from Rotte

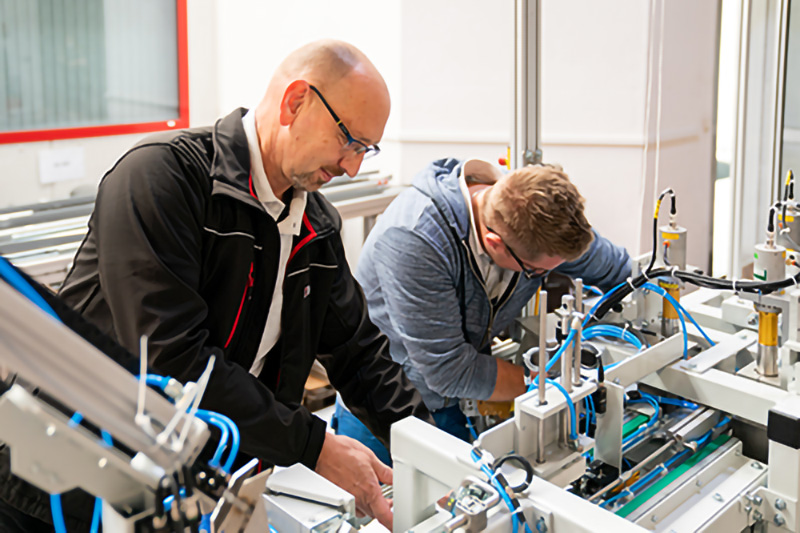

The success of a project in process and production technology depends not only on technical implementation but primarily on comprehensive planning. At Ulrich Rotte, we accompany you from the initial idea to the complete commissioning of your facility.

It begins with a detailed analysis of your existing processes and production environments. Together with you, we develop a concept that takes into account your specific requirements and simultaneously allows room for future developments. In the design phase, our experienced engineers use state-of-the-art CAD tools to create precise models and check technical feasibilities.

The subsequent manufacturing process takes place in our own production facility, where we ensure the highest quality standards. After assembly, the commissioning takes place directly at your site, including comprehensive tests to ensure a smooth production start. Of course, we also offer training for your personnel so that you can fully utilize the potential of your new facility.

But our service does not end with the commissioning: We also stand by you afterwards with comprehensive after-sales service. Whether regular maintenance, quick spare parts supply, or process optimizations – we ensure that your facilities continue to operate efficiently and reliably.

Contact us today so we can support your processes!

One Company, Many Advantages

Ulrich Rotte Anlagenbau & Fördertechnik GmbH is your specialist in custom machinery. In addition to our innovative solutions in special-purpose machinery and automation technology, you also benefit from a wide range of customer and after-sales services:

Your Advantages at a Glance:

- Decades of experience in special-purpose machinery

- Extensive know-how across all areas of automation technology

- High expertise in the latest technologies and applications for Industry 4.0

- All services from a single source—from development and design to manufacturing, assembly, commissioning, and regular on-site maintenance

- Optional training of your machine operators, technicians, and supervisors at your facility

- Mechanical engineering made in Germany – we design and manufacture exclusively in Germany

- Personalized customer support – you will always have a qualified contact person available

Our products

Industrial Measurement Technology & Automation

Customized Measurement Systems for Your Business Precision measurement technology is a fundamental component of modern ...

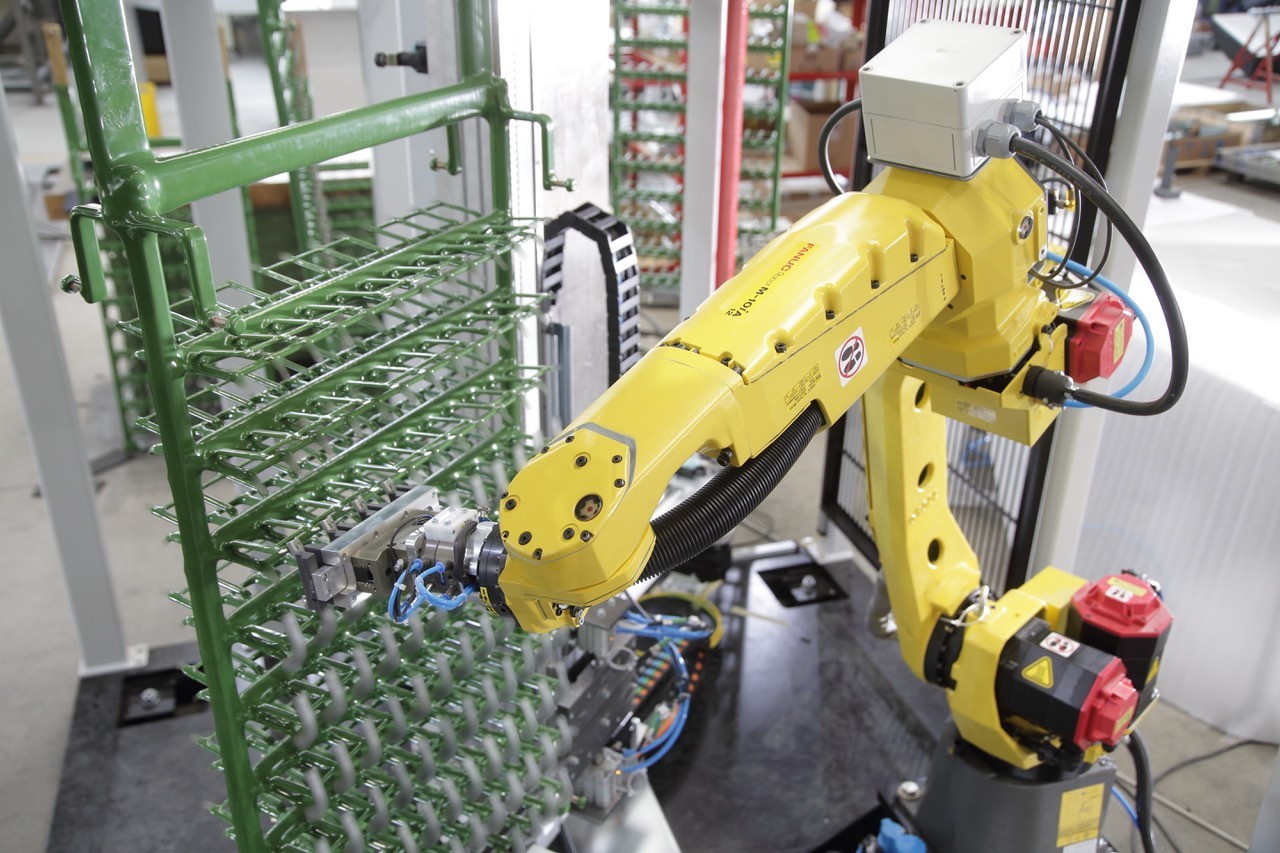

Automatic Rack Loading Systems

Efficient, safe, precise: Automated rack loading with system Whether powder-coated components, painted workpieces, or heat-treated ...

Bin Picking Zelle CAMGripX-1200

Precise and reliable Bin Picking In modern industrial production, every second counts. Companies are increasingly ...

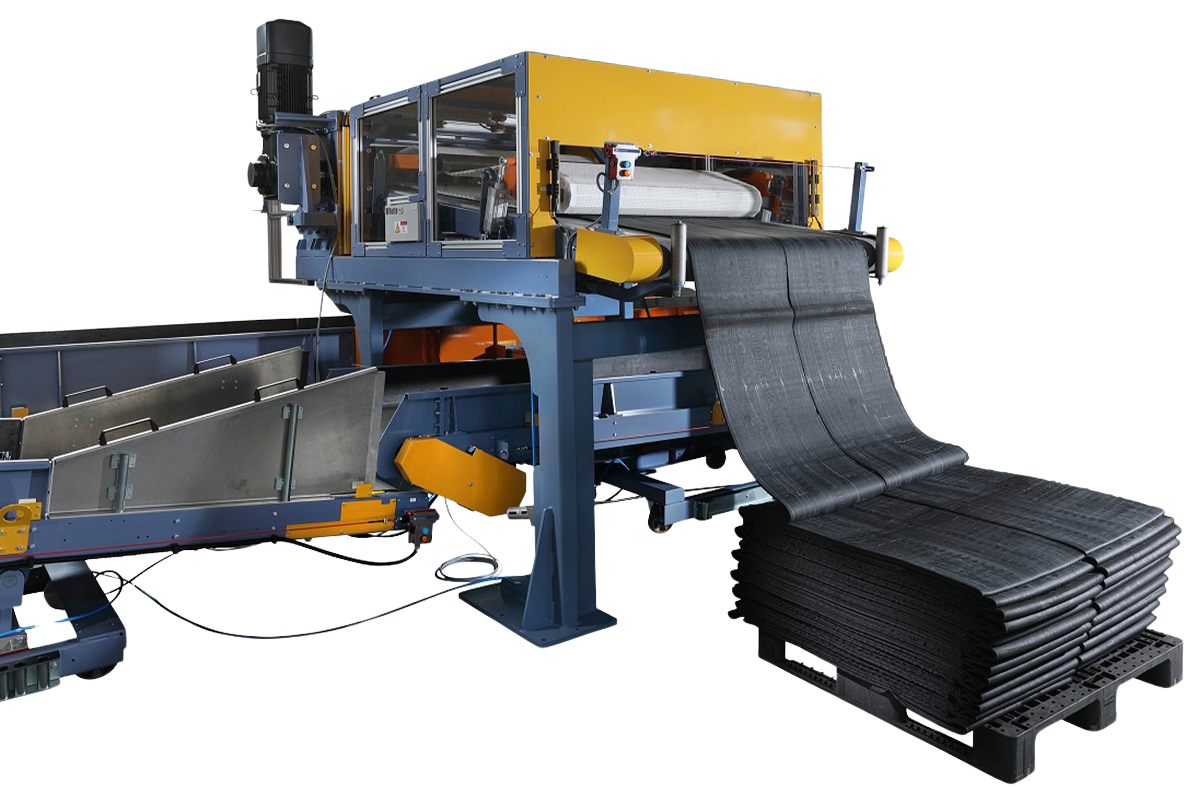

Thermoforming Machine

Precision meets innovation – thermoforming technology for demanding fibre materials For the industrial processing of ...

Batch Feeder

Flexible automation solutions for controlled material flow Our systems are fully customizable and seamlessly integrate ...

Automated Punching

We manufacture your custom punching machine as a special solution High-precision punching of molded parts ...

In-Line and End-of-Line Testing

The implementation of automated End-of-Line (EOL) and In-Line testing systems enables companies to make their ...