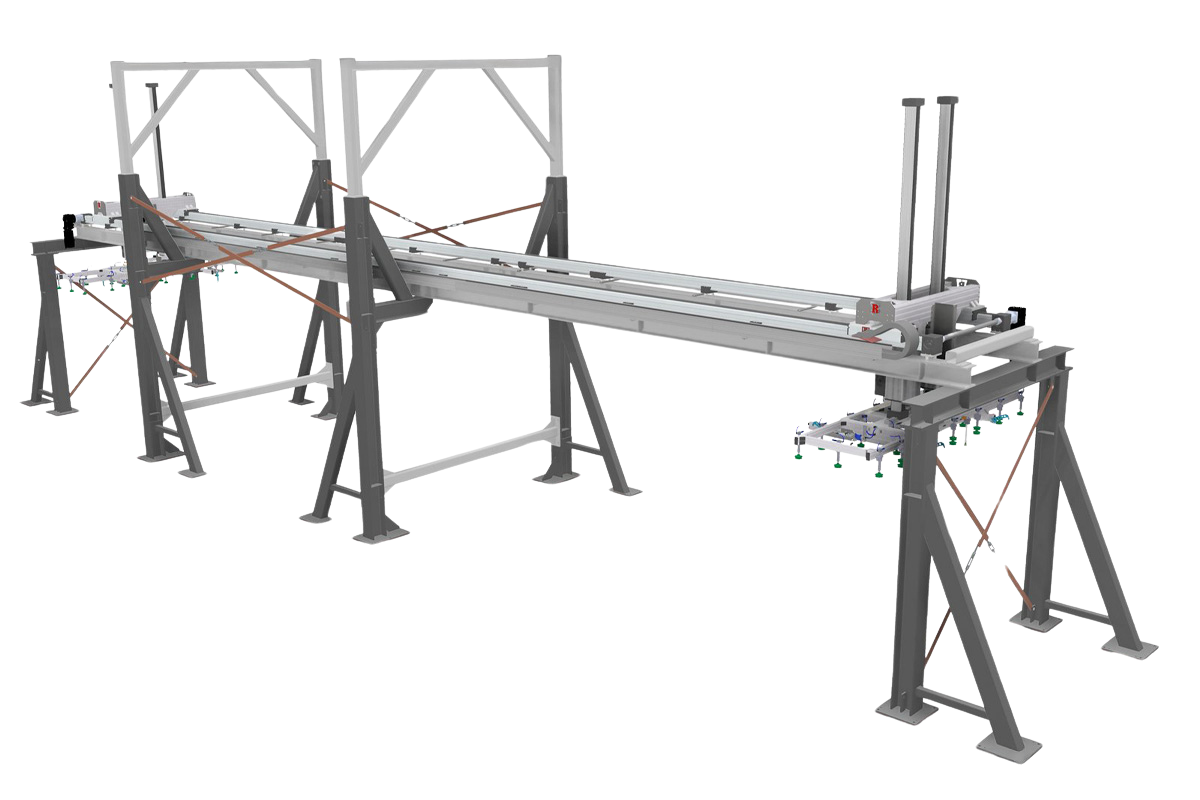

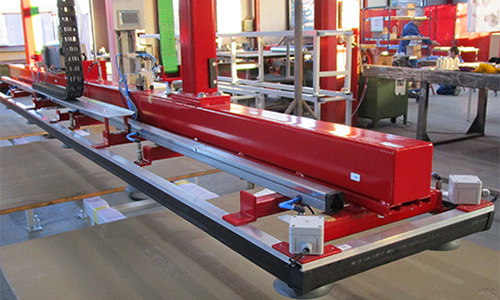

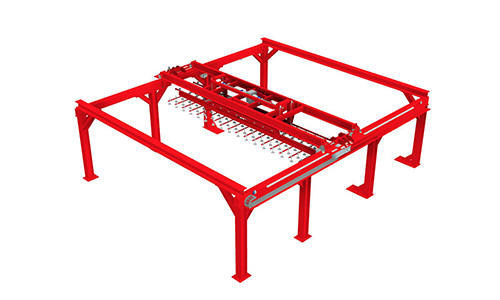

Automation makes packing and handling processes significantly more efficient. In modern manufacturing, automation significantly enhances stacking and handling processes. When it comes to the automated movement of components, workpieces, or packaging units—especially during stacking and unstacking—fast, precise, and dependable systems are essential to boost productivity and reduce manual labor.