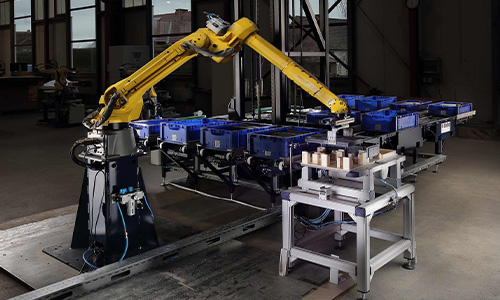

Rotte develops tailor-made automated small parts storage systems precisely aligned with your production requirements. In many industries, handling small parts is a critical step in the manufacturing process. Components such as screws, electronic parts, and delicate precision elements must be stored in predetermined containers, boxes, or trays—organized efficiently and with maximum space utilization. Manual storage and retrieval of such components can result in rising error rates as throughput increases. To streamline material flow, reduce access times, and maximize warehouse capacity, automated storage systems are the ideal solution.