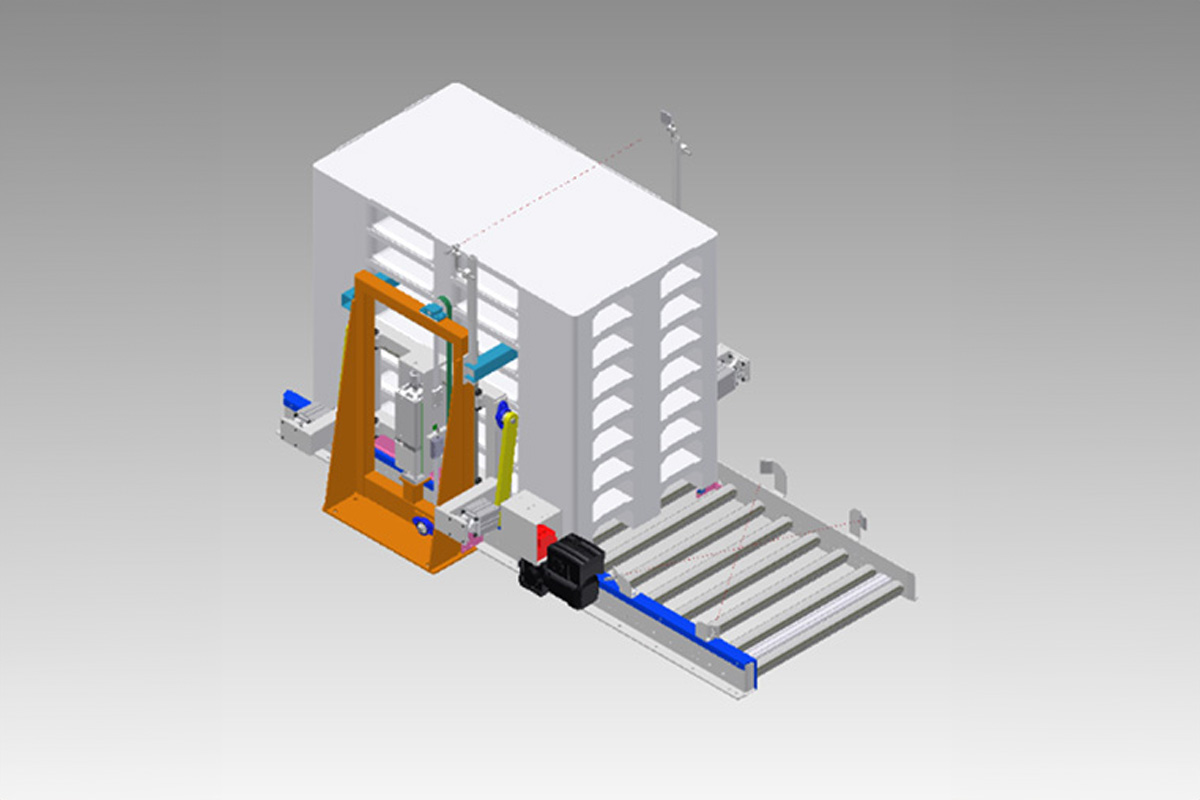

Effortless Stacking and Destacking with Variable Capacity

Efficient solutions for the automatic stacking and separation of pallets are needed across nearly all industrial sectors. Whether in the automotive industry, mechanical engineering, packaging, or food processing—wherever goods are transported, stored, or shipped, pallets play a central role. Yet special sizes and unique pallet shapes often pose challenges for automated handling. Manual pallet handling, on the other hand, is frequently inefficient, space-consuming, and prone to errors.