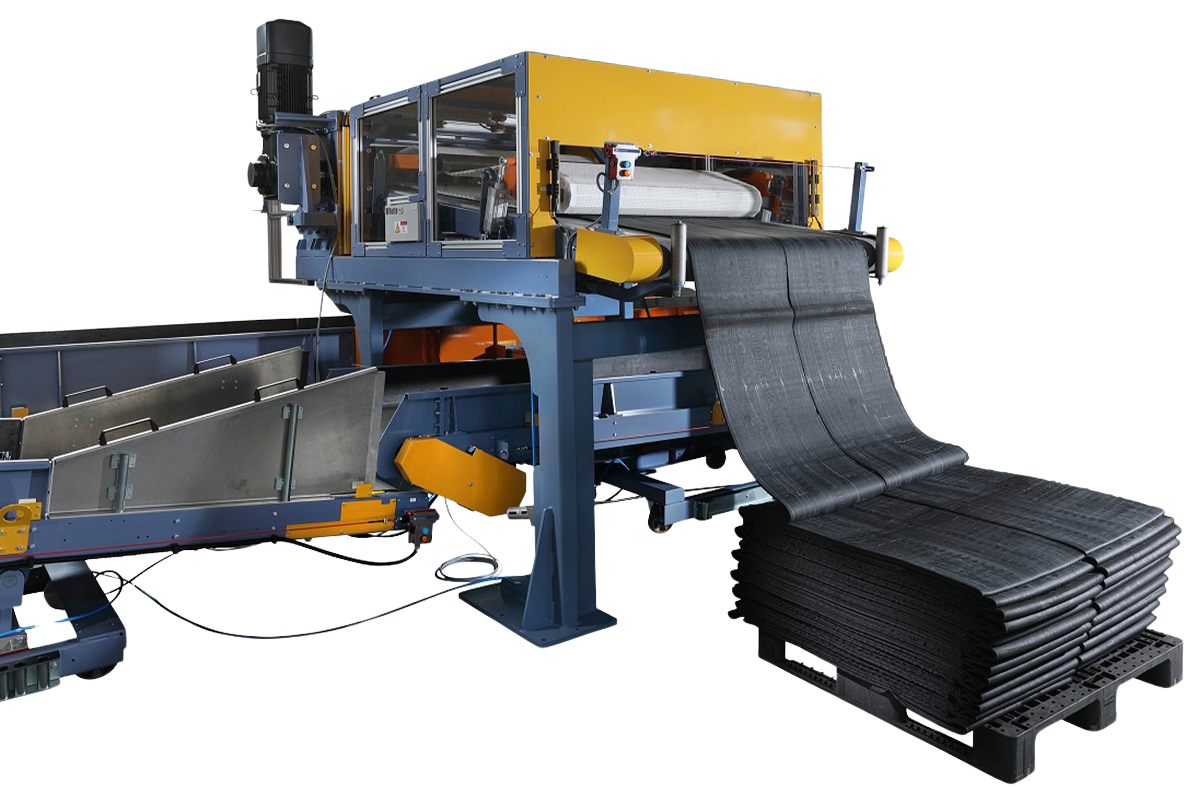

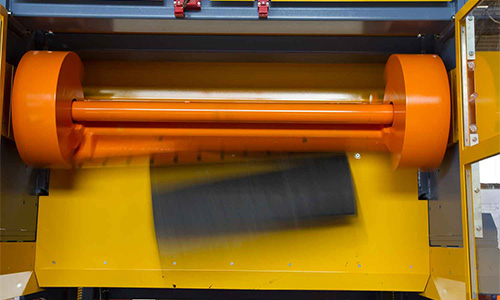

Rotte’s batch feeding solutions offer a flexible, high-precision, and automated platform for the controlled delivery of material batches in rubber and elastomer production.

Our systems are fully customizable and seamlessly integrate into existing production lines. This allows for safe, efficient, and precise material flow management—minimizing downtime, reducing scrap, and significantly improving product quality.