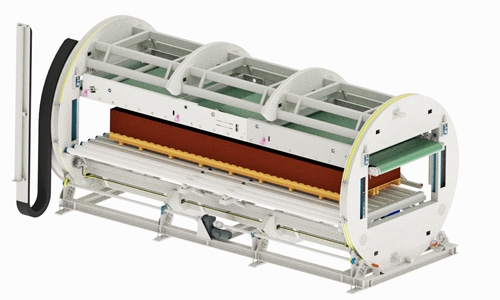

When Everything Revolves Around Your Workpieces

Turners for panels of all material types: In many industrial applications, products such as panels, pallets, and other large components must be rotated. Safe and precise turning is essential to prepare parts for downstream processing steps while avoiding material damage. Especially when dealing with large, heavy, or delicate workpieces, manual turning is often impractical or requires significant effort and time. Automated custom solutions are the key to ensuring an efficient material flow and reducing operator strain.