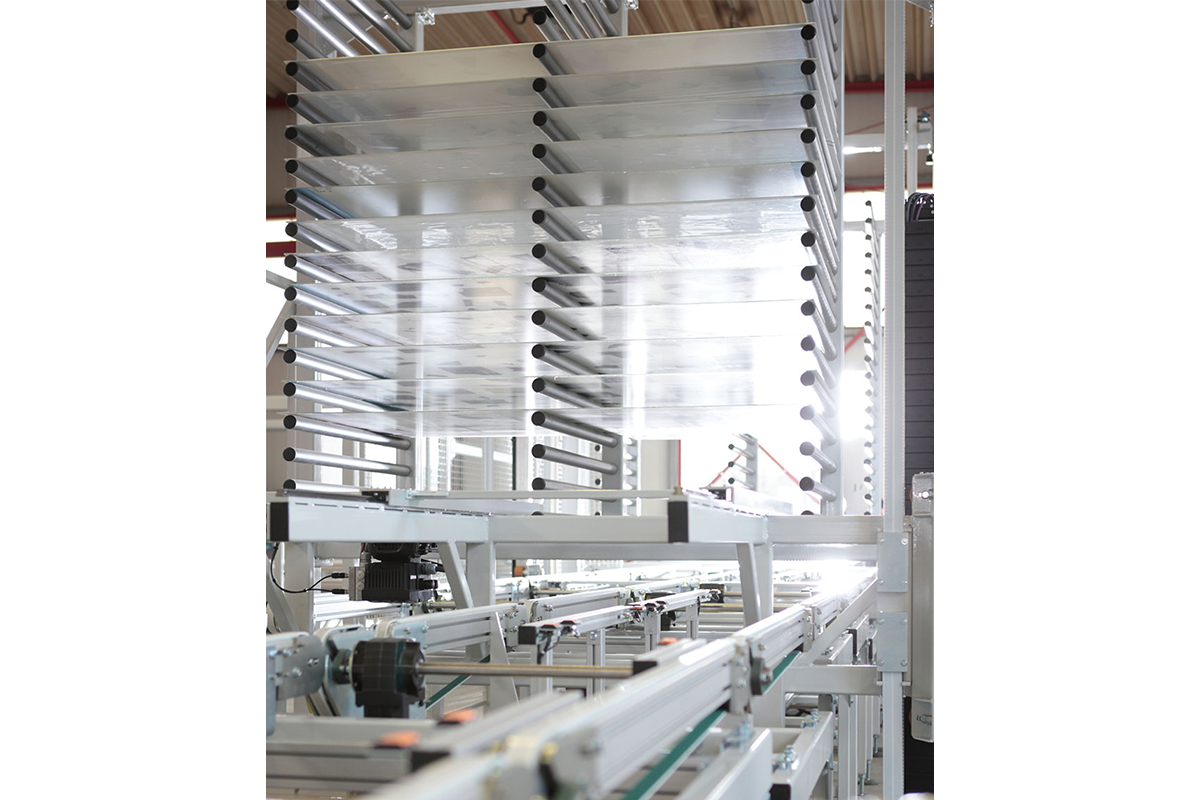

Rotte develops efficient material flow systems for optimized production to increase output and prevent disruptions. Especially in automated manufacturing and logistics, the continuous availability of components, semi-finished products, or perishable goods is critical. Rotte’s FIFO storage systems (First In, First Out) ensure that materials are supplied in a defined sequence through demand-oriented shelving systems, keeping production processes perfectly synchronized.