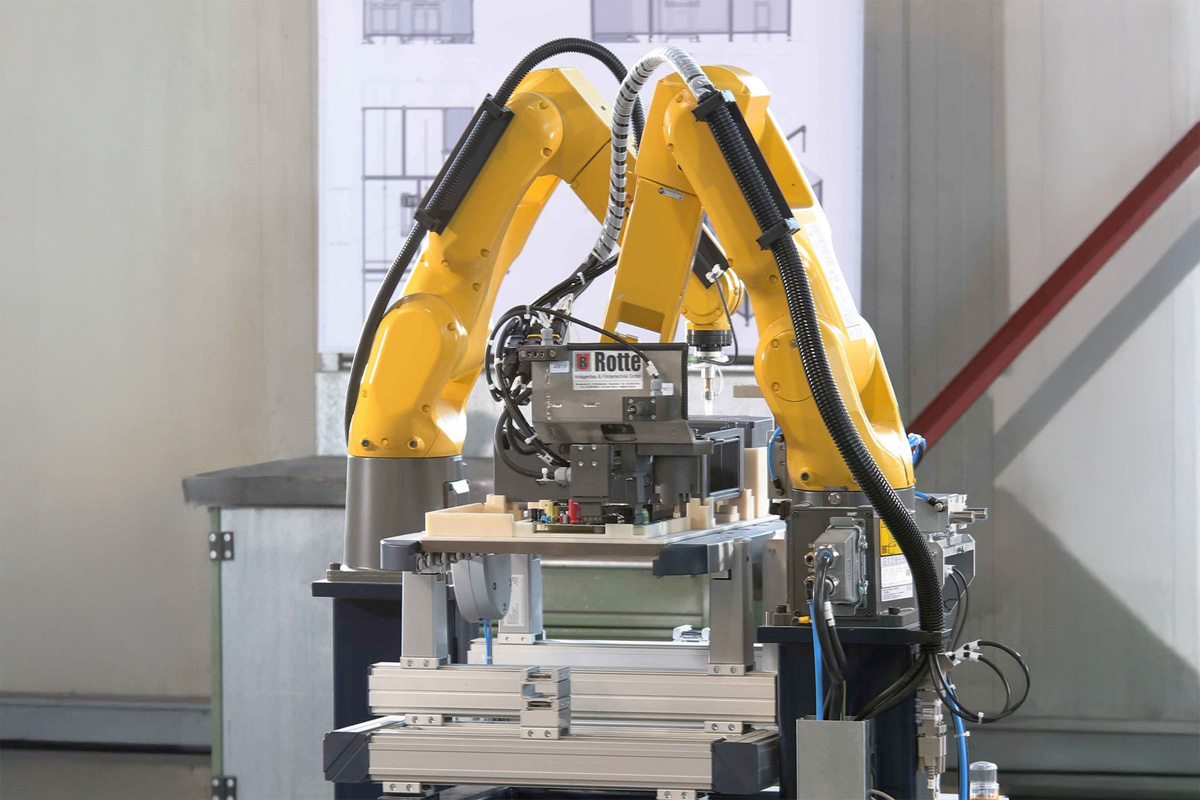

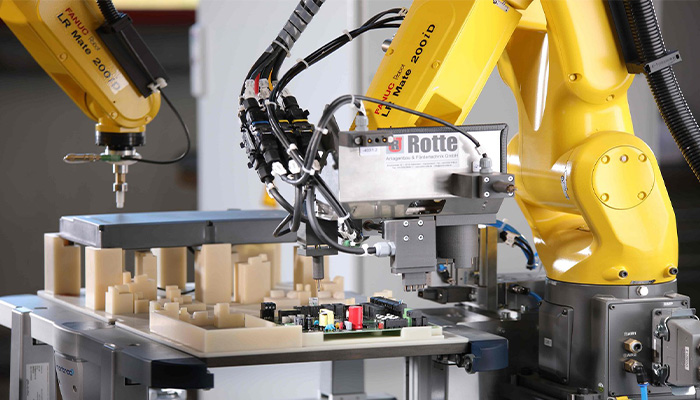

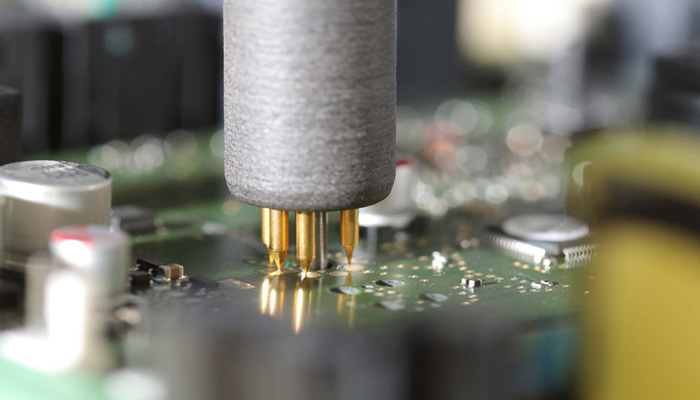

The implementation of automated End-of-Line (EOL) and In-Line testing systems enables companies to make their production processes not only more efficient but also more sustainable. By combining improved quality, reduced costs, and increased flexibility, you too can gain a clear competitive advantage in an increasingly dynamic market environment.