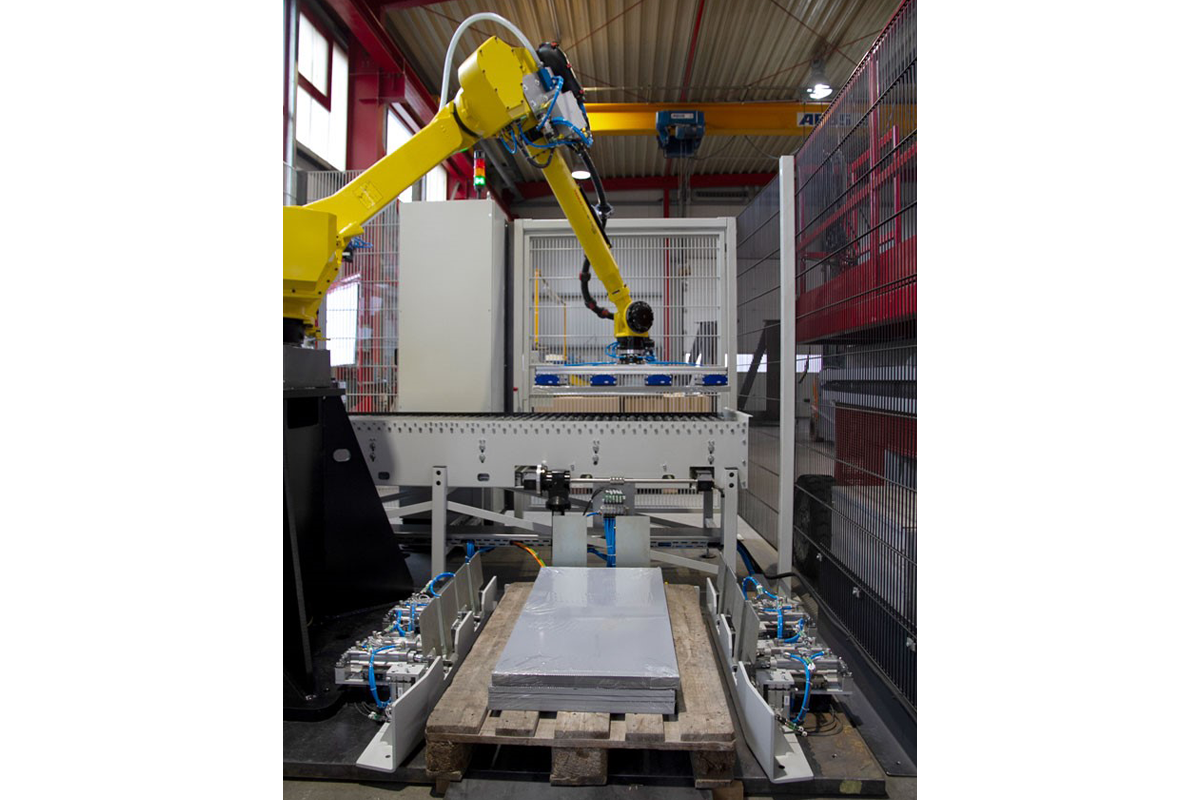

Smart Automation for Precise and Efficient Stacking

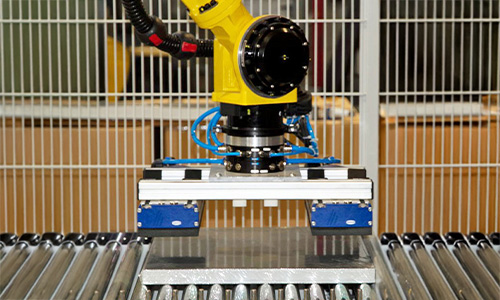

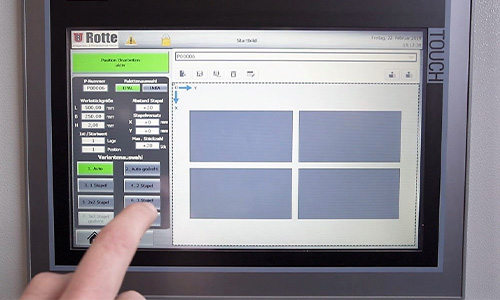

In today’s industrial environments—with their complex production and logistics workflows—automated stacking of products and components has become indispensable. By using automatic loading and stacking robots, materials can be handled efficiently and precisely. Rotte delivers the technical solutions. Our industrial robots for stacking, loading, and unloading are already optimizing production workflows in many companies, reducing error rates, and automating manual tasks. Especially in industries with high volumes or delicate components, precise stacking ensures gentle handling and secure storage.