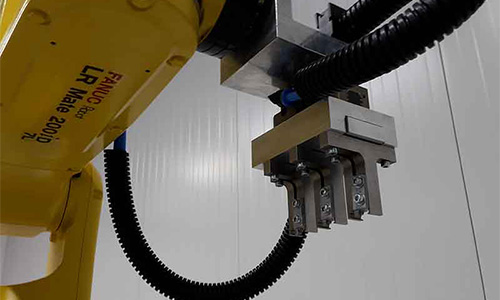

Harness the full potential of Rotte’s robotics expertise for truly efficient part handling: We develop pick-and-place robot solutions tailored precisely to the individual needs of each client. Our robots handle parts with exceptional repeatability—boosting your production capacity while reliably eliminating avoidable errors. Discover what makes material handling efficient, flexible, and cost-effective—and how we can help you achieve it.