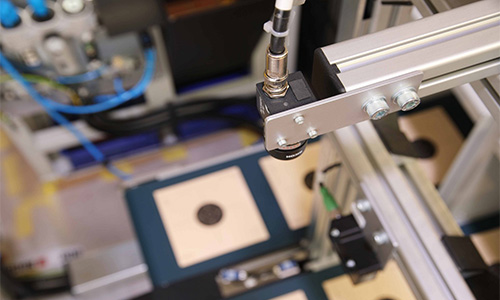

We manufacture your custom punching machine as a special solution

High-precision punching of molded parts is a crucial production step in many industries. Especially in the automotive, aerospace, construction, and packaging sectors, components must be pierced, perforated, or stamped with exact fit to meet functional or assembly-related requirements. Traditional manual processing quickly reaches its limits in terms of efficiency, precision, and reproducibility.