Assembly Automation

Custom Assembly Automation Systems

Efficient and Precise Automation Solutions for Your Production

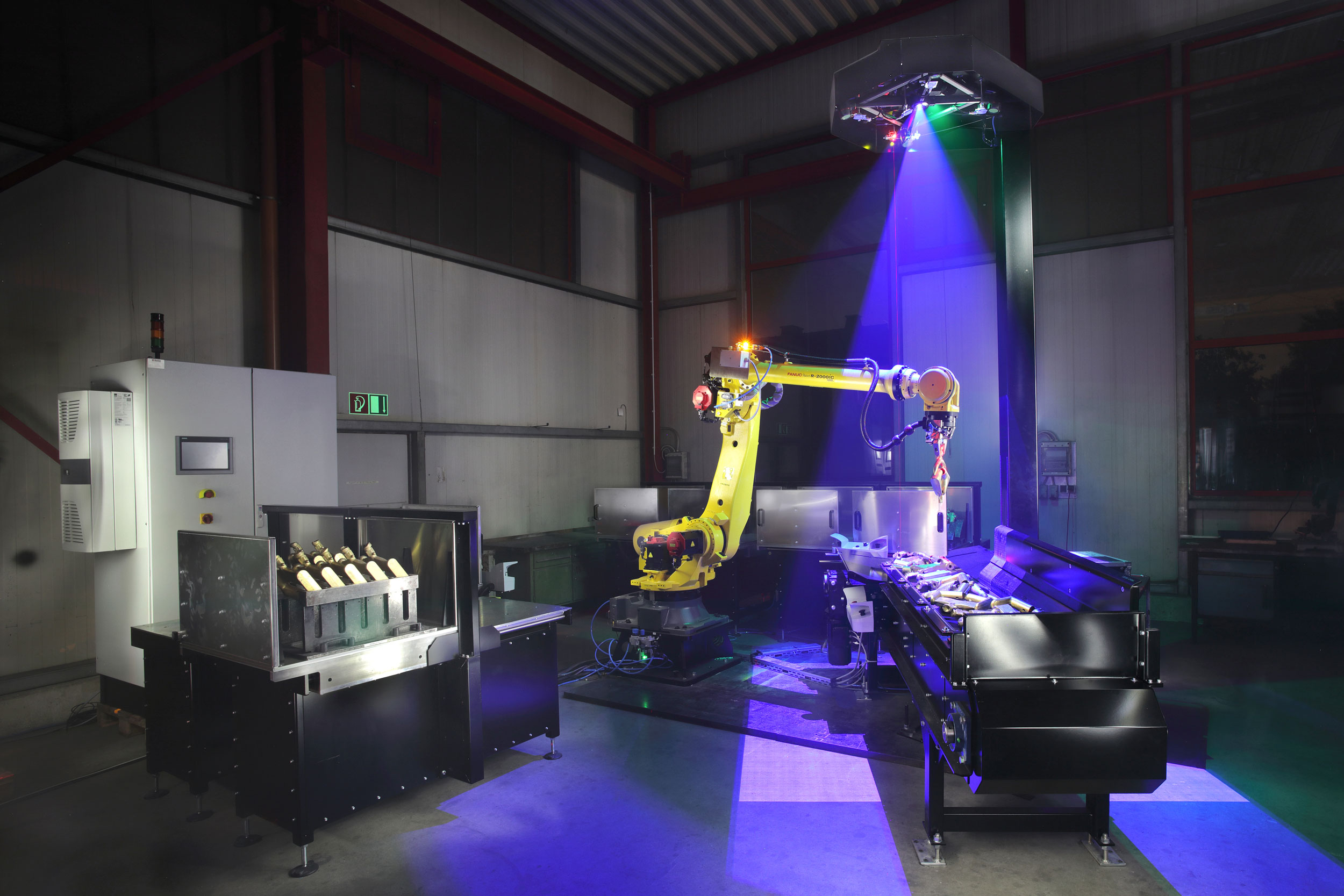

Today’s industrial manufacturing faces increasing demands for precision and efficiency—especially in the assembly of components and subassemblies. To remain competitive, more and more companies are turning to assembly automation that optimizes production processes, reduces manual intervention, and enhances product quality.

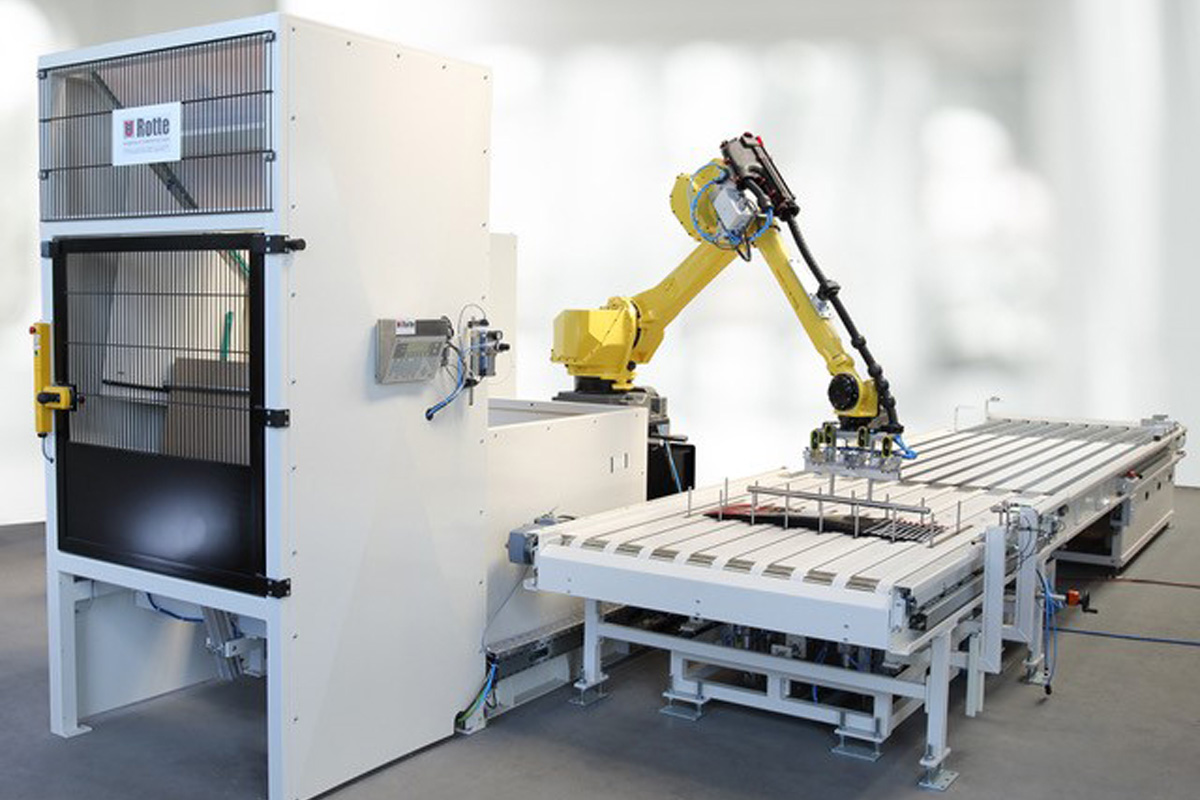

Rotte develops fully integrated assembly technology tailored precisely to the requirements of each client’s production environment. Our special-purpose machines and systems enable fast, error-free, and efficient workflows, increase reliability, and ensure high process stability as well as improved cost-effectiveness.

Your contact person

Daniel Bürgermeister

Technical sales & project planning

Daniel Bürgermeister

Technical sales & project planning

Automating Your Assembly Processes with Rotte

Automated assembly offers numerous advantages over manual processes. It increases productivity, reduces error rates, and lowers operating costs over the long term. Where repetitive tasks can be handled by machines, your employees’ expertise can be focused more effectively on value-adding activities. Rotte’s custom systems and robotic technologies cover a wide range of applications while delivering strong advantages across the board:

Increased Efficiency and Faster Production Cycles

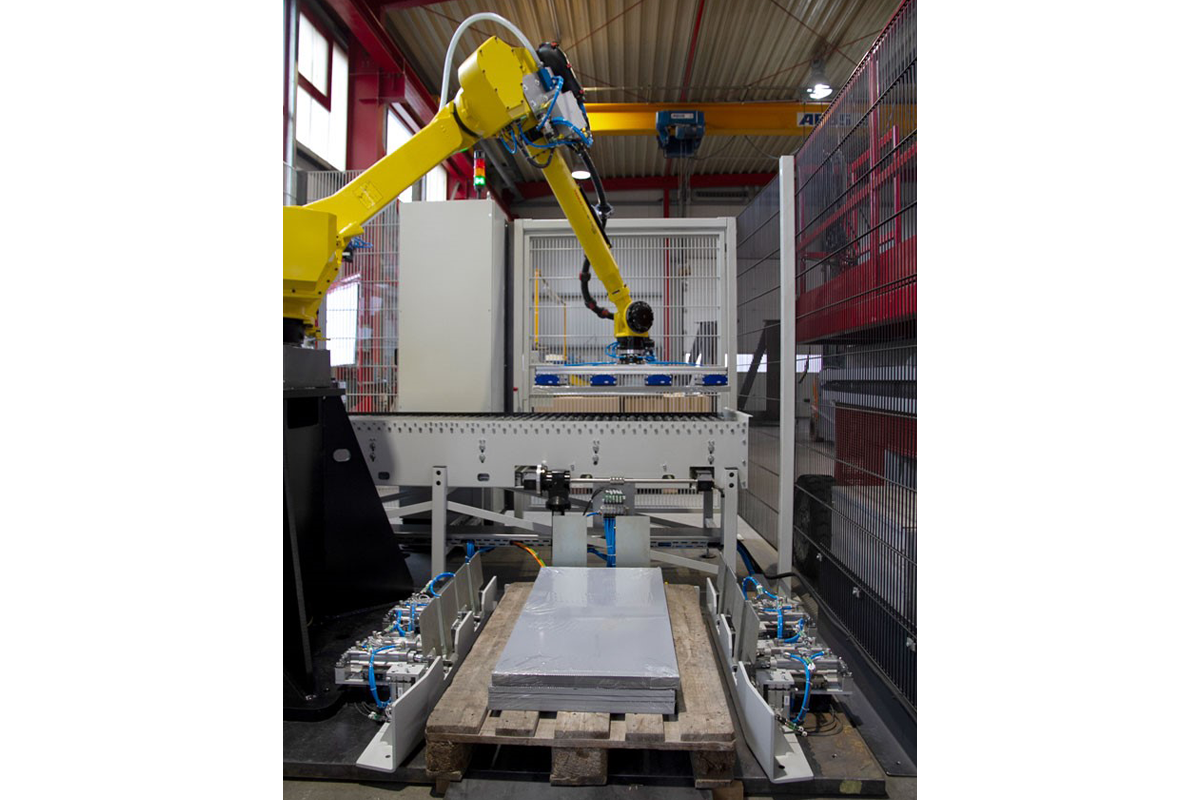

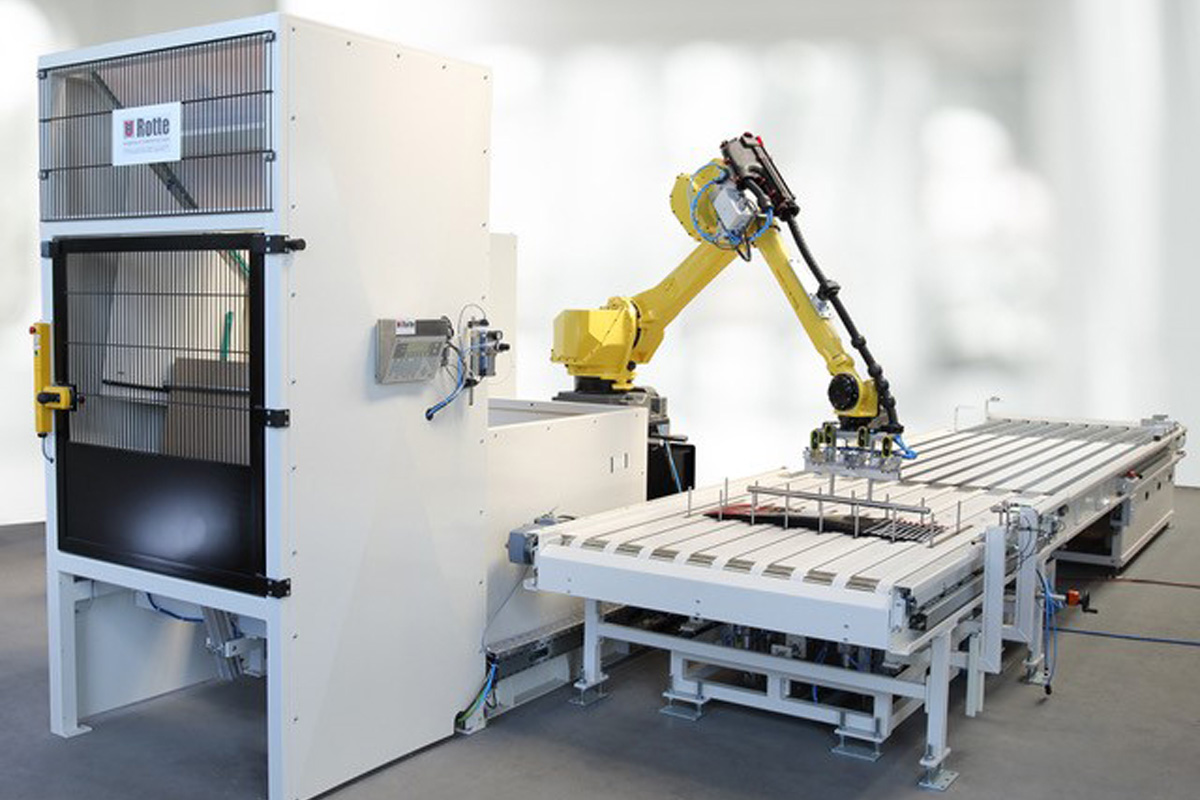

As a manufacturer of robotic assembly systems, automated screwdriving or adhesive units, and precision handling systems, we help reduce your production times significantly. Individual parts are positioned, assembled, and inspected with repeatability that manual stations can no longer achieve.

Consistent Quality and Lower Error Rates

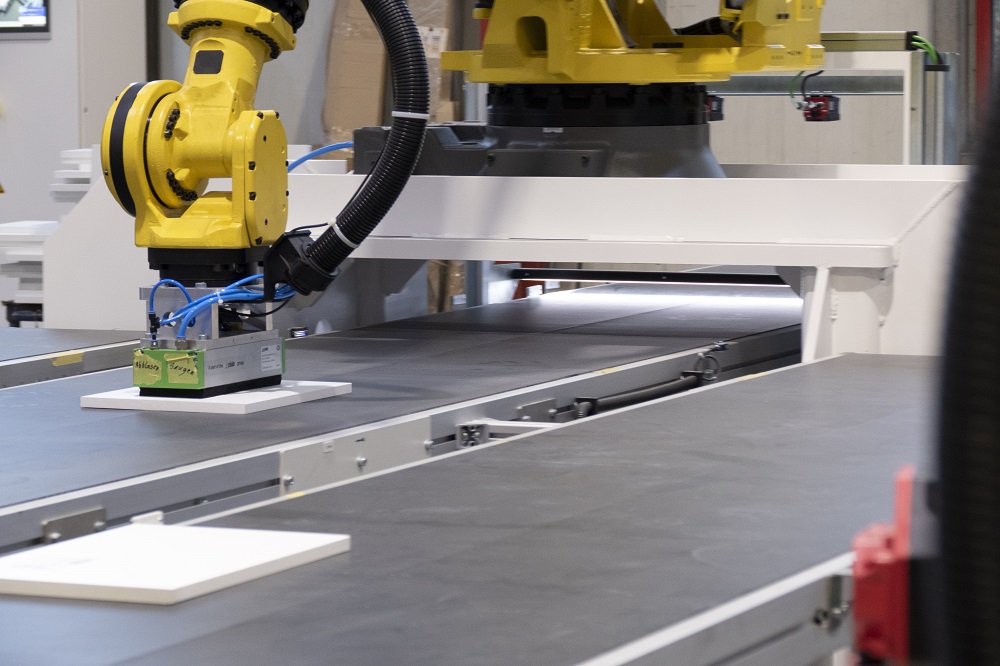

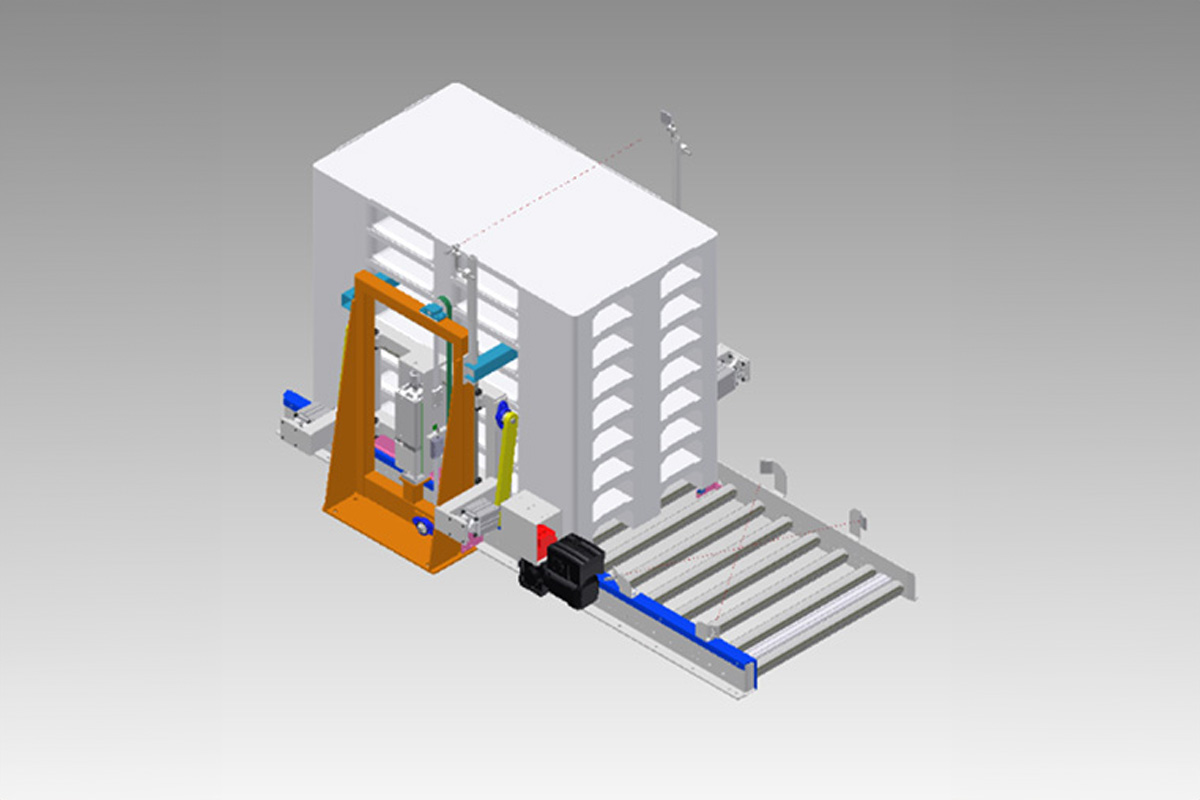

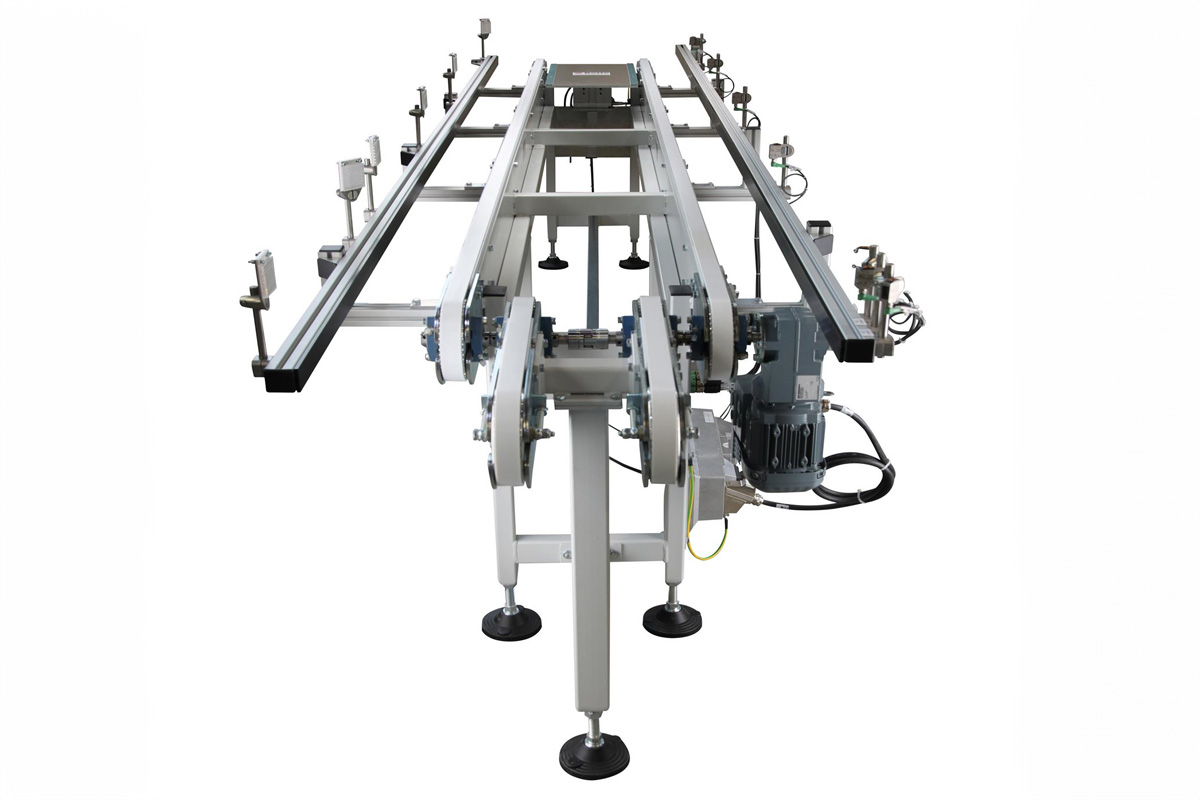

Automated assembly systems ensure consistently high assembly quality, performing more accurately and reliably than even the most experienced staff. As a result, scrap is reduced, rework minimized, and customer satisfaction increased. Once calibrated, Rotte’s fully automated solutions ensure gentle handling of all types of components—from loading and unloading, machine feeding, and part removal via modular transfer systems to customer-specific assembly processes based on your exact requirements.

Improved Working Conditions and Ergonomics

Handling heavy or complex assemblies can place physical strain on workers. Automated systems take over repetitive or physically demanding tasks, relieving staff and allowing them to focus on supervision or skilled work. With minimal human intervention, our smart automation systems can screw, press-fit, mount, bond, and perform all necessary steps in the assembly process. We take care of both hardware implementation and precise control system programming.

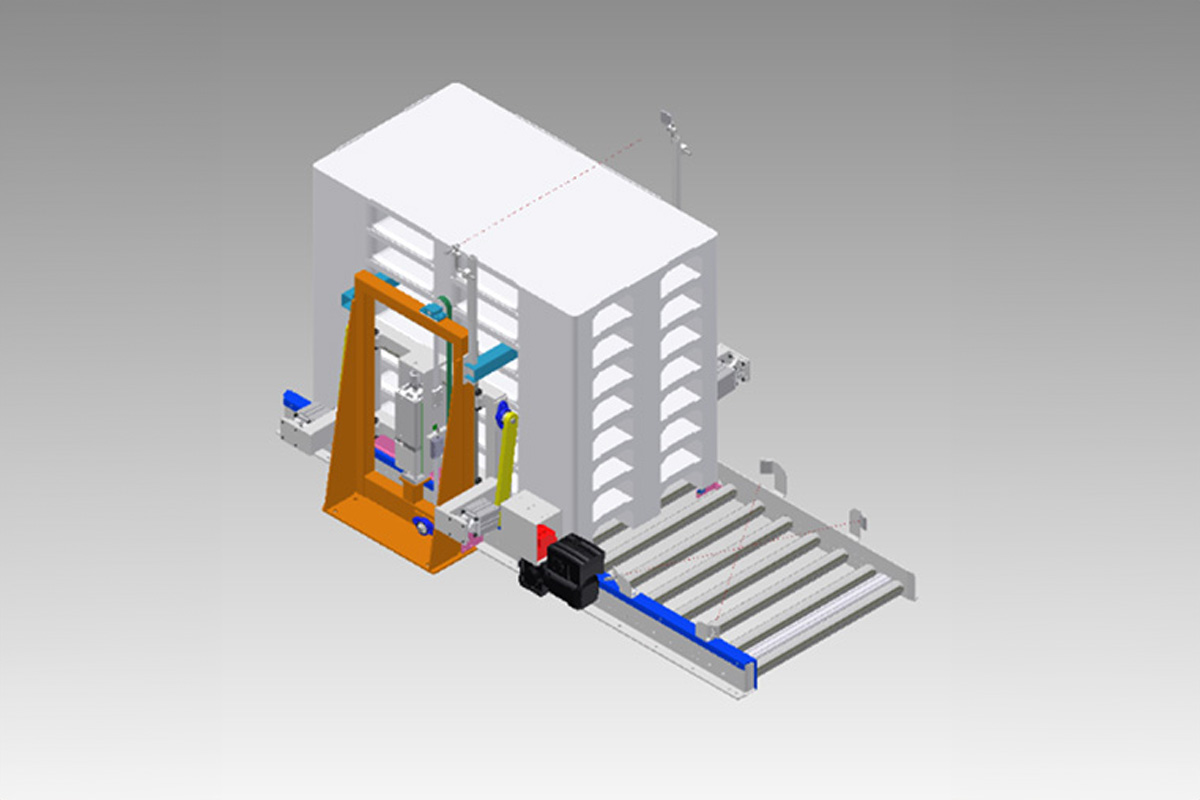

Flexibility for Handling Diverse Product Variants

Rotte’s advanced assembly automation systems offer unparalleled flexibility in a compact footprint, easily adapting to varying product types or production volumes. Thanks to intelligent control systems and custom plant designs, our systems are future-proof and can be quickly adjusted to new requirements. We can even design your assembly line to enable fast switching between highly customized and standardized processes.

Why Choose Rotte Solutions?

Our tailor-made automation solutions offer significant advantages for companies looking to make their production more reliable and cost-effective.

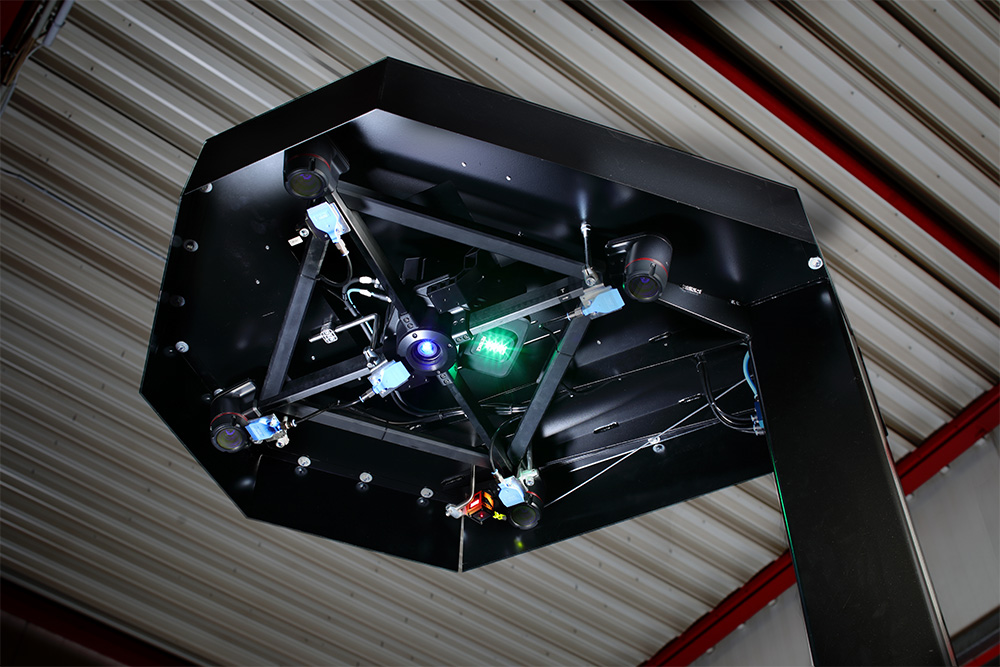

- Maximum precision: Accurate positioning and reliable assembly through cutting-edge robotics and sensor technology

- Increased productivity: Faster production cycles through automation and intelligent control systems

- Flexibility: Modular system architecture for adaptable, multi-variant manufacturing

- Cost savings: Reduced manual labor and lower operating costs through optimized processes

- Reliable quality assurance: Integrated testing and monitoring systems for error prevention

- Seamless integration: Smooth connectivity to upstream and downstream production systems

Technology for Precise and Reliable Assembly Automation

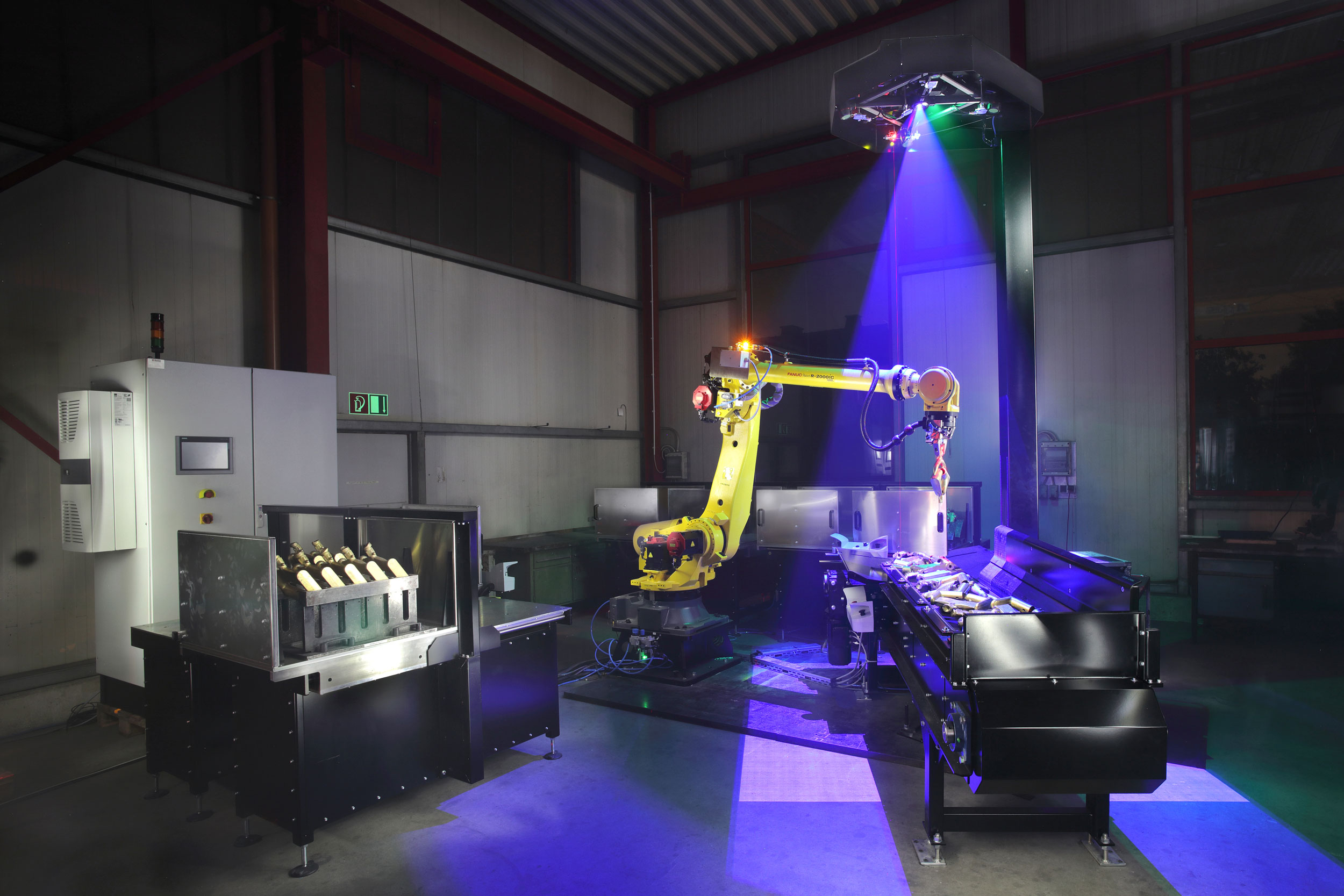

Our assembly automation solutions are based on advanced robotics, precision control, and smart sensor technology—allowing you to fully leverage the benefits of Industry 4.0.

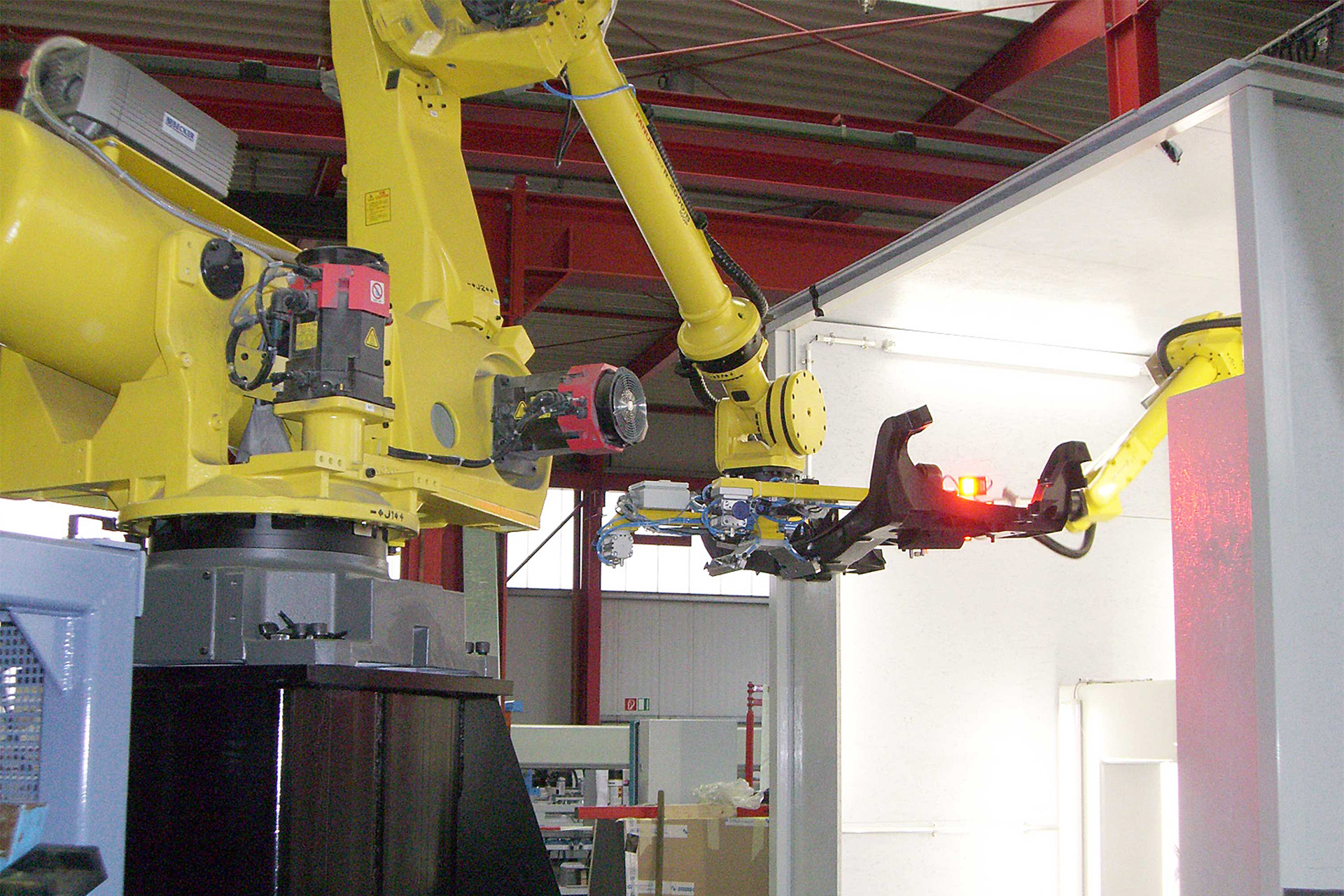

Robotic Manufacturing Processes for Maximum Precision

By using industrial robots, even complex assembly steps can be automated. Our robots are equipped with intelligent gripping and handling systems that position, assemble, and inspect each component with precision.

Flexible Handling of Different Components

Our assembly solutions are designed to handle a wide variety of parts and materials. Depending on your application, we implement various gripping technologies, screwdriving systems, welding, or adhesive units—allowing you to standardize tasks that previously required manual customization.

Integrated Quality Assurance and Process Monitoring

Our robotic systems feature built-in testing and monitoring tools to ensure that every component is correctly assembled. Using cameras, sensors, and force-torque monitoring, each process step is tracked in real time to detect and prevent errors early.

Application Areas of Our Technical Platforms

Our automation solutions are used across a wide range of industries where precise, fast, and reliable component assembly is required.

Automotive Industry

In automotive production, numerous components must be assembled with precision—from body parts and engines to electronic modules. Our robotic assembly systems ensure high-speed production and consistent quality.

Electrical and Electronics Industry

In the manufacturing of circuit boards, sensors, microchips, and full systems for e-mobility and consumer electronics, maximum precision and cleanliness are essential. Our fully automated assembly systems enable contamination-free, error-free processing and, if desired, complete traceability of individual parts.

Mechanical and Plant Engineering

Assembling machines and complex systems requires the accurate fitting of many parts. Our intelligent handling solutions ensure secure and error-free component assembly, even in variable production scenarios.

Medical and Pharmaceutical Industry

The production of medical devices demands extreme care and process safety. Our automation solutions ensure precise and hygienic assembly of sensitive products in a sector that combines standard components with many custom-designed parts.

Furniture and Woodworking Industry

In furniture manufacturing, many assembly steps are increasingly automated. Our systems handle tasks such as connecting cabinet parts, attaching hinges, packaging finished products, and gentle part handling—even at high cycle speeds.

Optimize Your Production Now – Modular Assembly Automation by Rotte

Our smart assembly systems enable future-proof, efficient, and error-free production of a wide range of products. They reduce error rates and sustainably optimize process efficiency. Designed with cost-effectiveness in mind, they’re precisely tailored to your needs and can be combined with supporting technologies to cover both upstream and downstream steps.

Benefit from our experience and let us advise you—professionally and without obligation. Get in touch with your personal contact at Rotte and learn more about custom automation solutions for your company!

One Company, Many Advantages

Ulrich Rotte Anlagenbau & Fördertechnik GmbH is your specialist in custom machinery. In addition to our innovative solutions in special-purpose machinery and automation technology, you also benefit from a wide range of customer and after-sales services:

Your Advantages at a Glance:

- Decades of experience in special-purpose machinery

- Extensive know-how across all areas of automation technology

- High expertise in the latest technologies and applications for Industry 4.0

- All services from a single source—from development and design to manufacturing, assembly, commissioning, and regular on-site maintenance

- Optional training of your machine operators, technicians, and supervisors at your facility

- Mechanical engineering made in Germany – we design and manufacture exclusively in Germany

- Personalized customer support – you will always have a qualified contact person available

Our products

Automated Storage Systems for Multi-Daylight Presses

In high-output production processes involving multi-daylight presses, efficient storage and automation solutions are essential for ...

Heavy-Duty Roller Conveyors

Heavy-duty roller conveyors from Rotte are an optional yet integral component of our complete solutions ...

Picking Robots

Robotic Order Picking: Efficient Automation for Precise and Flexible Logistics with Customized Picking Robots In ...

Bin Picking Cell CAMPGripX-1200

Precise and reliable Bin Picking In modern industrial production, every second counts. Companies are increasingly ...

Bag and Pouch Packaging Machine

Efficient and Flexible Packaging Solutions Rotte develops fully customized packaging machines for pre-made bags and ...

Automatic Pallet Magazine

Effortless Stacking and Destacking with Variable Capacity Efficient solutions for the automatic stacking and separation ...

Belt Conveyors

Custom Conveyor Solutions for Your Production Efficient material flow is essential in modern production and ...

Drum Turner

When Everything Revolves Around Your Workpieces Turners for panels of all material types: In many ...

Thermoforming Machine

For the industrial processing of sealing fleece, filters, and technical fiber materials, Rotte offers high-precision ...

Loading and Stacking Robots

Smart Automation for Precise and Efficient Stacking In today’s industrial environments—with their complex production and ...

Automated Storage Systems for Multi-Daylight Presses

In high-output production processes involving multi-daylight presses, efficient storage and automation solutions are essential for ...

Heavy-Duty Roller Conveyors

Heavy-duty roller conveyors from Rotte are an optional yet integral component of our complete solutions ...

Picking Robots

Robotic Order Picking: Efficient Automation for Precise and Flexible Logistics with Customized Picking Robots In ...

Bin Picking Cell CAMPGripX-1200

Precise and reliable Bin Picking In modern industrial production, every second counts. Companies are increasingly ...

Bag and Pouch Packaging Machine

Efficient and Flexible Packaging Solutions Rotte develops fully customized packaging machines for pre-made bags and ...

Automatic Pallet Magazine

Effortless Stacking and Destacking with Variable Capacity Efficient solutions for the automatic stacking and separation ...