Material Provisioning

Efficient Feeding for Your Production

More than just a machine builder: With Rotte’s broad expertise, you benefit from the full innovation capacity and versatile solution strategies of a seasoned manufacturer of automation systems and custom production technology.

Precise and reliable material provisioning is the key to efficient production and effective value chain optimization. Workstations become more ergonomic, and even high-frequency order cycles can be fulfilled on time. Only when components, materials, and semi-finished products are available at the right time, in the right quantity, and at the right location can production processes run smoothly. Delays in provisioning lead to production stops, unnecessary costs, and quality fluctuations. With Rotte’s expertise, optimizing your material flow and logistics becomes effortless.

Your contact person

Daniel Bürgermeister

Technical sales & project planning

Optimized Material Flows for Maximum Efficiency

Traditional manual material provisioning quickly reaches its limits in modern production environments. Long search times, incorrect material assignments, or inefficient inventory management directly impact productivity. Automated provisioning systems solve these issues by intelligently managing material flows and avoiding bottlenecks.

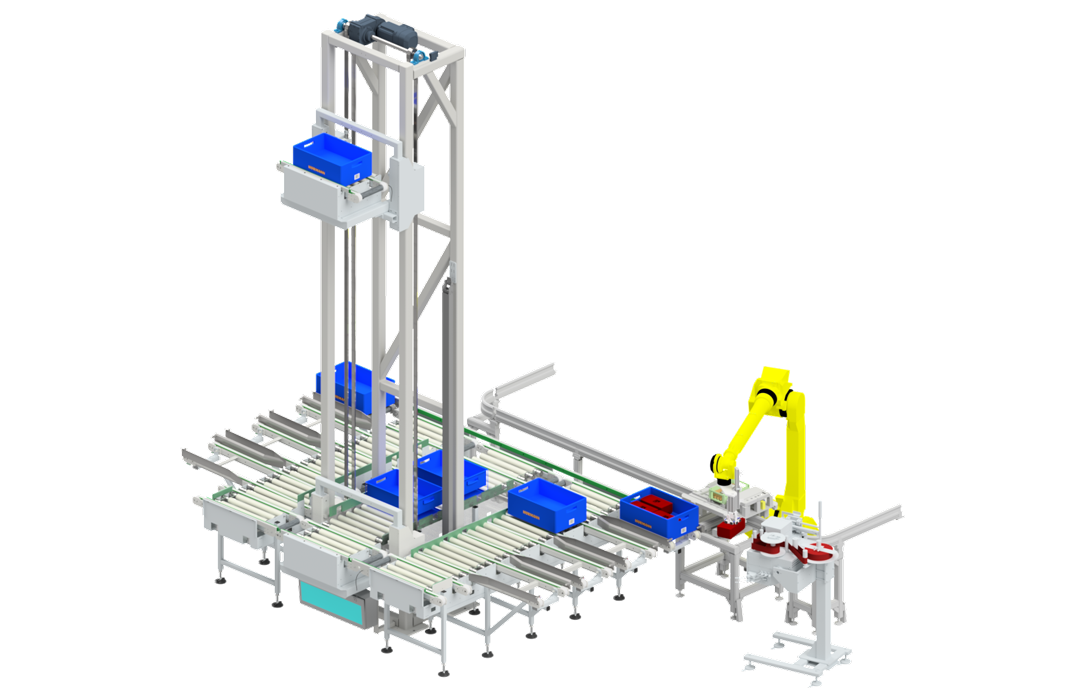

A customized feeding system from Rotte enables demand-driven and cycle-accurate provisioning—even with high material variety—ensuring reliable output planning. Whether for assembly lines, CNC machining centers, or packaging stations, we use automated conveyor systems, robotics, and sensor-based control systems to ensure that each component reaches its destination in the correct order and quantity.

An efficiently designed provisioning system not only improves production throughput, but also reduces inventory levels and internal transport costs. Thanks to flexible control concepts, our solutions can dynamically adapt to changing production requirements—resulting in increased productivity and lower operating costs.

Technology That Drives Production Forward

Rotte’s modern provisioning systems combine intelligent conveyor systems, robot-based feeding solutions, and digital control concepts.

Conveyor Systems for Precise, Timed Material Delivery

Automated material provisioning depends on conveyors that transport components, materials, or packaging units accurately and efficiently. Depending on the application, we implement belt conveyors, roller conveyors, gravity conveyors, or chain conveyors.

Our systems can be seamlessly integrated into existing production environments. Smart sensors and controllers ensure perfect synchronization with downstream production steps, delivering materials exactly when they’re needed—without delays or overstock.

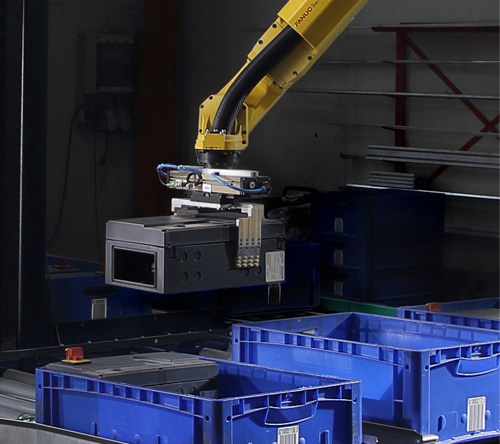

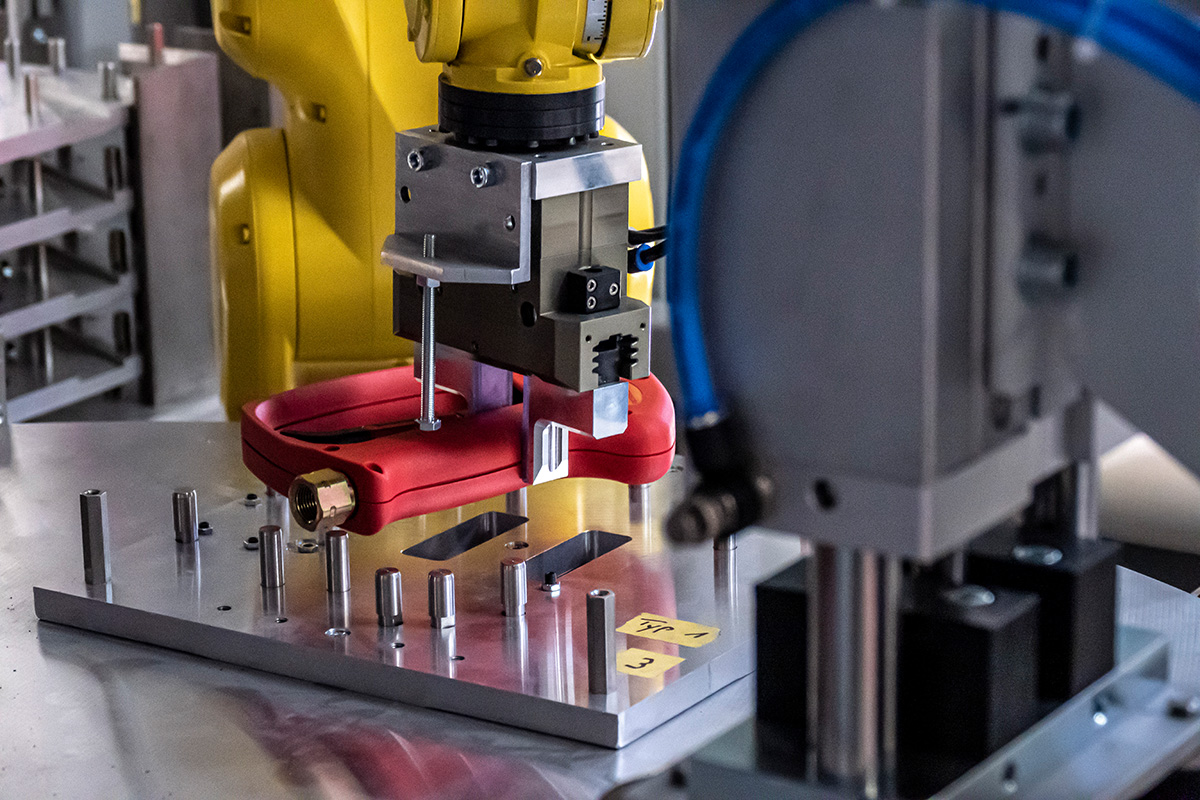

Robot-Based Feeding Systems for Precise Material Handling

In addition to conventional conveyors, robotic solutions are playing an increasingly vital role in material provisioning. Our feeding systems utilize industrial robots to securely grip, position, and insert components directly into production machinery or assembly lines.

Thanks to advanced gripping and sensor technologies, our robots can safely handle fragile, irregularly shaped, or difficult parts. The result is fewer errors in material supply and significantly enhanced process reliability.

Intelligent Control and Connectivity for Maximum Flexibility

Modern production demands intelligent control systems that monitor and optimize material flows in real time. Our provisioning systems are equipped with powerful control and IoT technologies that enable demand-driven and adaptive material supply for Industry 4.0.

By integrating with existing ERP and MES systems, material flows can be automatically aligned with current production schedules. Sensor-based monitoring tracks inventory levels and triggers restocking processes—fully automated and without manual intervention.

Applications for Our Material Provisioning Solutions

Our provisioning solutions are widely used across industries.

In the automotive sector, our feeding systems ensure that parts like body components, engine modules, or cable harnesses are delivered in the correct sequence to assembly lines—minimizing downtime and supporting efficient production cycles.

In electronics, our systems provide timed delivery of PCBs, semiconductors, and assemblies—using gentle handling technologies for sensitive components, custom-tailored to your application.

In the food industry, our systems ensure hygienic, gentle, and reliable provisioning of packaged and unpackaged goods—efficiently feeding them into processing and packaging lines.

The Advantages of Our Material Provisioning Systems

A precise and efficient material provisioning system is a critical success factor in any production environment. With Rotte’s customized solutions, you benefit from numerous advantages that make your operations more competitive long-term.

Optimize Your Production with Material Provisioning Systems by Rotte

Automated and precise material provisioning gives you a decisive edge. With Rotte’s tailored solutions, you increase efficiency, cut costs, and enhance process reliability

Contact us today for a personalized consultation—our experts are ready to support you!

- Increased productivity: Materials are delivered in the right quantity, at the right time.

- Reduced downtime: Automated systems minimize waiting times and manual input.

- Lower costs: Optimized provisioning reduces inventory and transport expenses.

- Less waste: Tailored material supply minimizes scrap.

- Higher process reliability: Automation prevents errors and ensures consistent flow.

- Better ergonomics: Physically demanding tasks are handled by smart conveyors and robots.

- Improved employee satisfaction: Staff can focus on more valuable tasks.

One Company, Many Advantages

Ulrich Rotte Anlagenbau & Fördertechnik GmbH is your specialist in custom machinery. In addition to our innovative solutions in special-purpose machinery and automation technology, you also benefit from a wide range of customer and after-sales services:

Your Advantages at a Glance:

- Decades of experience in special-purpose machinery

- Extensive know-how across all areas of automation technology

- High expertise in the latest technologies and applications for Industry 4.0

- All services from a single source—from development and design to manufacturing, assembly, commissioning, and regular on-site maintenance

- Optional training of your machine operators, technicians, and supervisors at your facility

- Mechanical engineering made in Germany – we design and manufacture exclusively in Germany

- Personalized customer support – you will always have a qualified contact person available

Our products

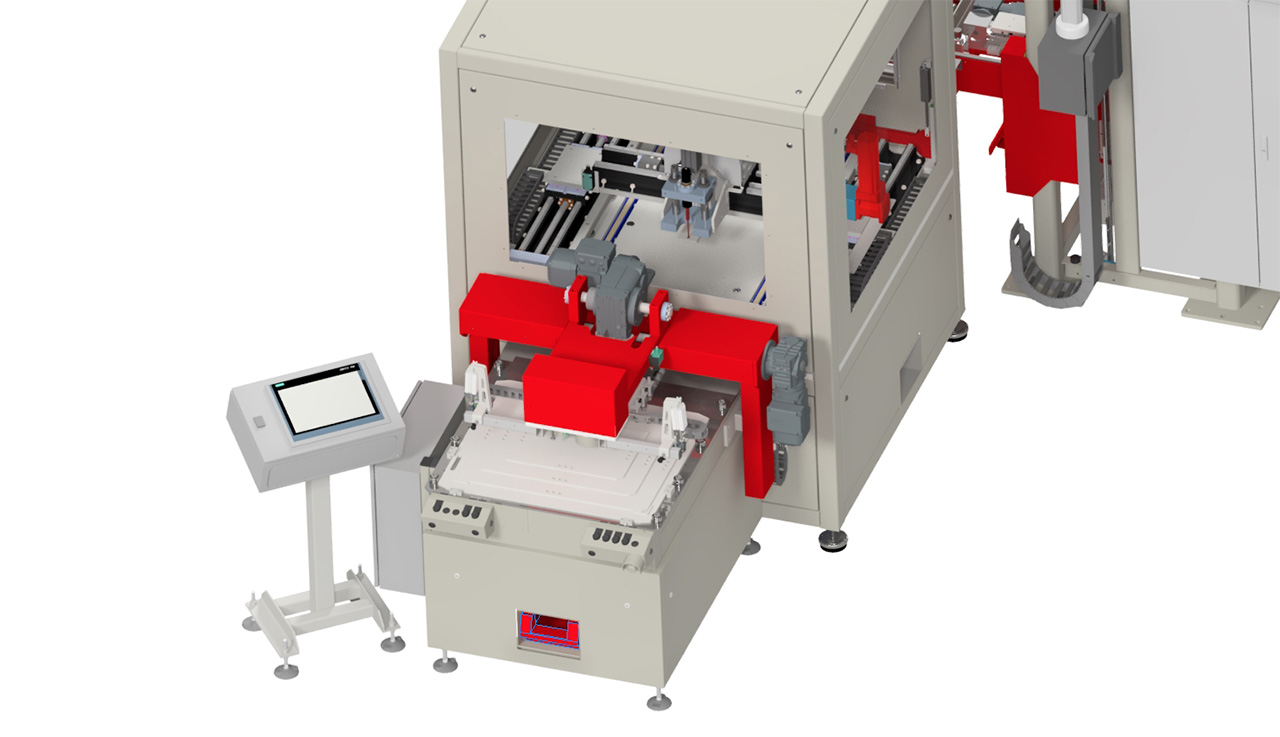

Lay-up station

Smart material supply for technical laminates and panels with Lay-up Stations from Rotte. In the ...

Flipping-Stations

Flipping material—without compromising quality or cycle time Whether for preparing lamination processes, two-sided processing, or ...

Breakdown Stations

Customized Breakdown Stations for your requirements Rotte designs tailored breakdown solutions precisely matched to your ...

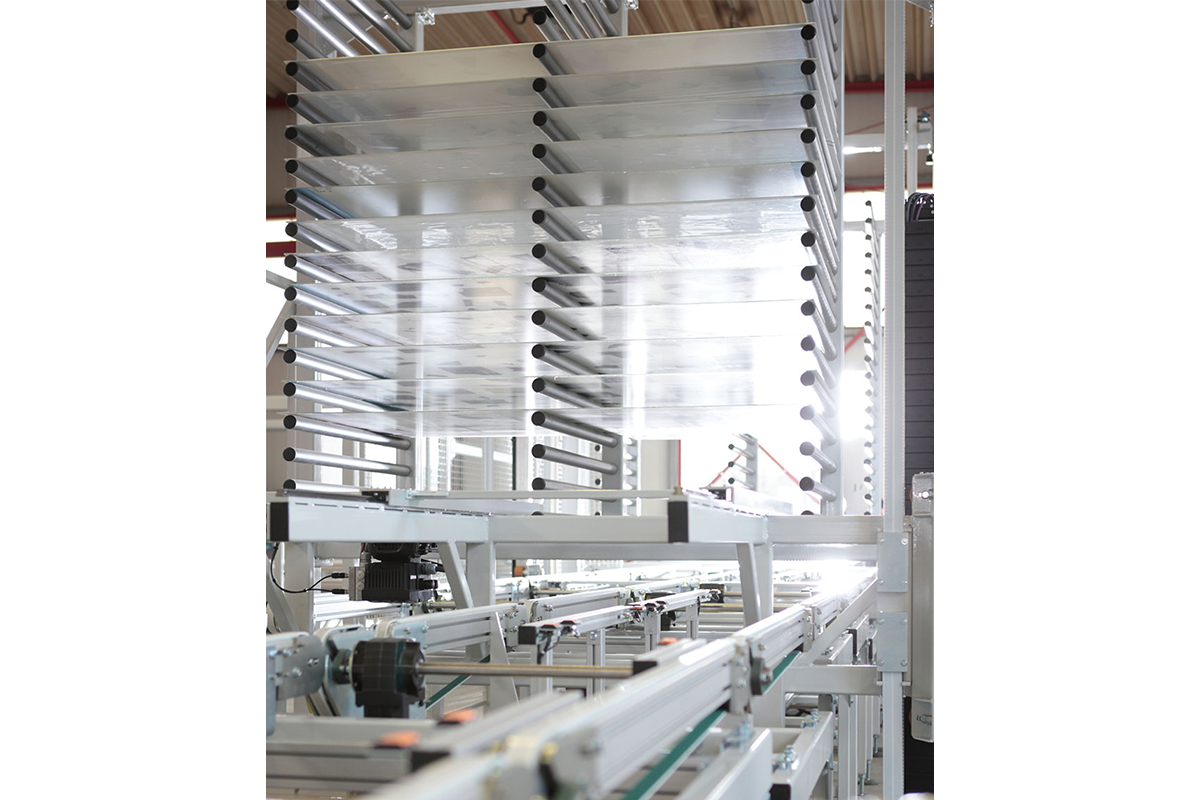

Automated Storage Systems for Multi-Daylight Presses

Perfect handling starts with the right gripper In high-output production processes involving multi-daylight presses, efficient ...

Drum Turner

When Everything Revolves Around Your Workpieces Turners for panels of all material types: In many ...

Pick-and-Place Robots

Rethinking parts handling – efficient, error-free, automated Harness the full potential of Rotte’s robotics expertise ...

Storage Systems for Slitter Knives

Efficient tool storage – ready to hand, protected and organised Efficient and secure storage of ...

FIFO Storage Systems

Intelligent material flow technology for trouble-free, automated production Rotte develops efficient material flow systems for ...

Automated Storage Solutions

Customized planning – perfectly aligned with your production Every ROTTE solution is custom-engineered based on ...