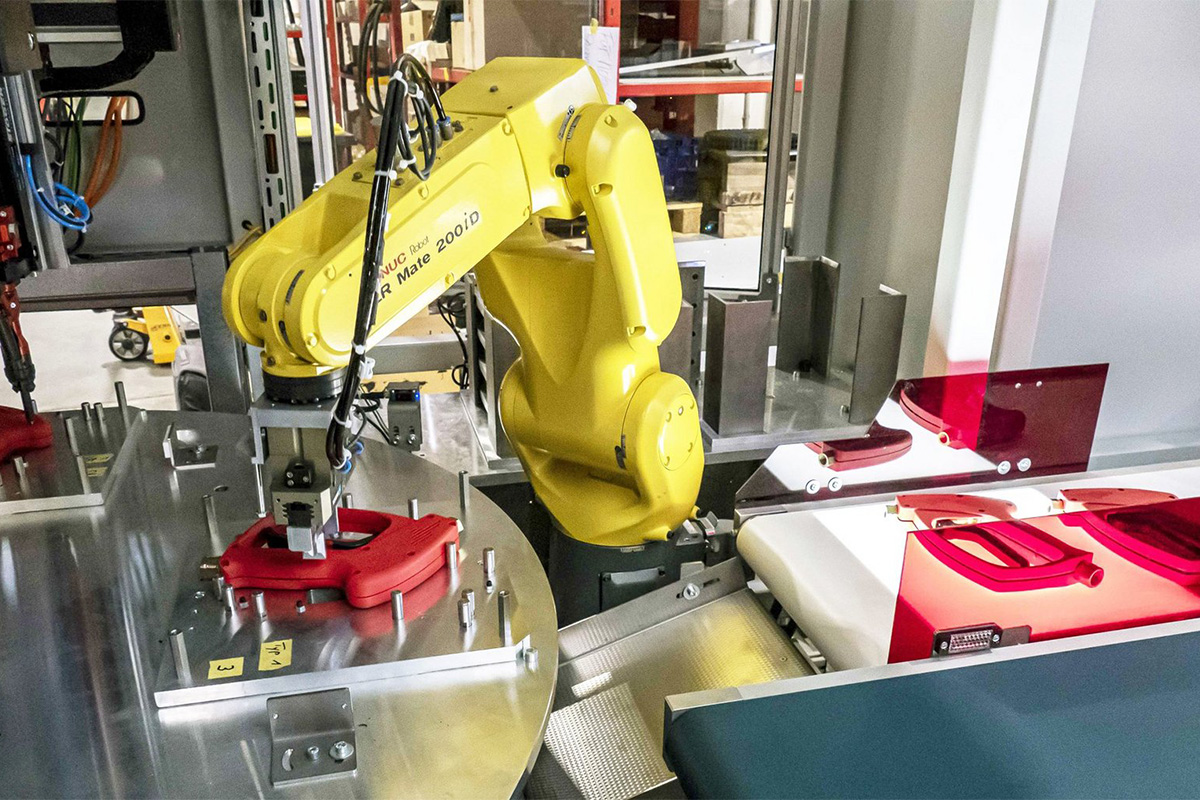

More productivity through customised assembly automation

Increase the Efficiency of Your Production with Automation: The manufacturing industry faces ever-growing demands for productivity, quality, and flexibility. Today’s companies must be capable of assembling complex assemblies and high-precision components quickly and with absolute reliability. Semi- or fully automated assembly systems from Rotte provide an innovative solution to meet these requirements. By using advanced robotic cells, assembly processes can be efficiently automated—reducing production costs, minimizing error rates, and optimizing cycle times. With customer-specific concepts and state-of-the-art control systems, we develop special-purpose machines and assembly systems tailored precisely to your needs.