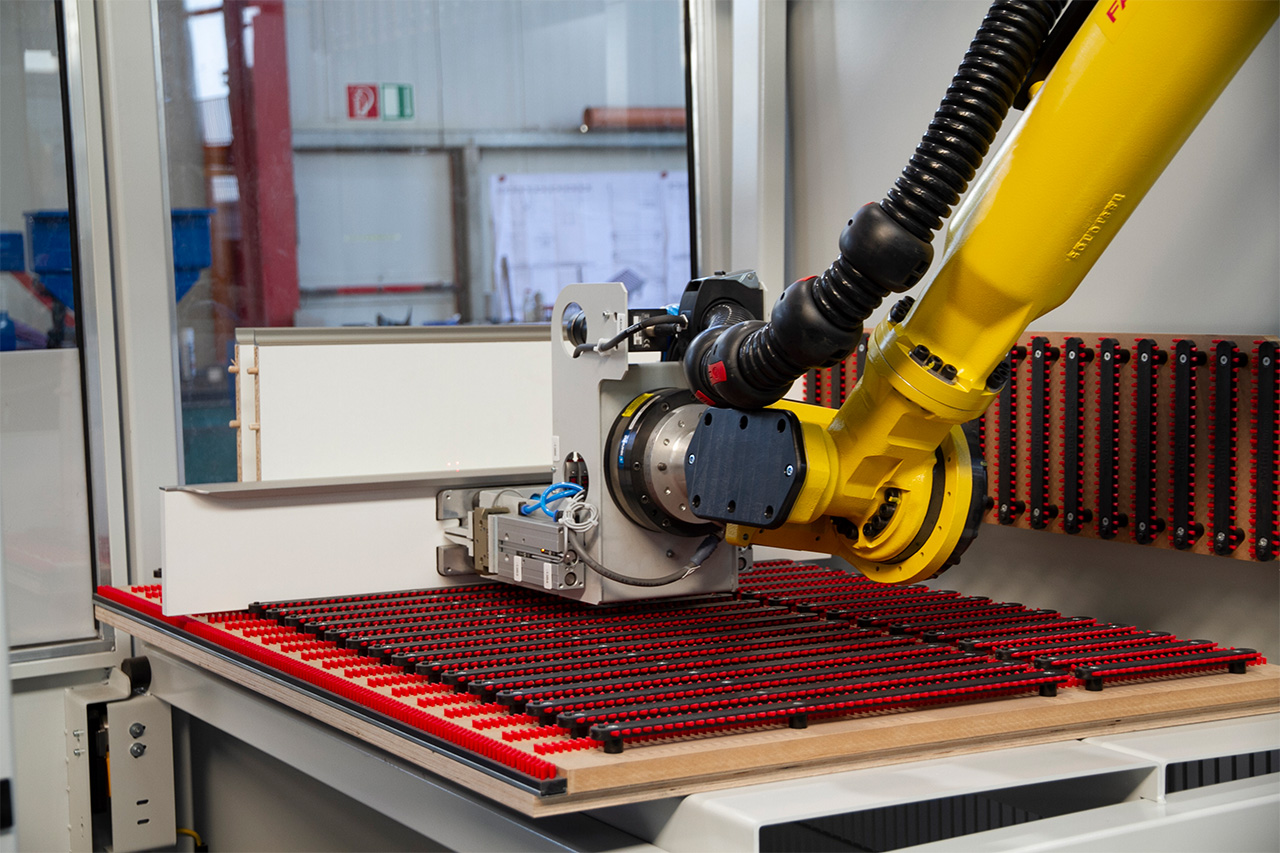

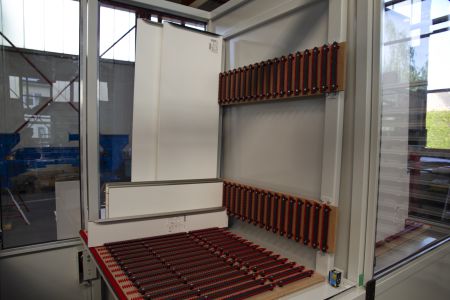

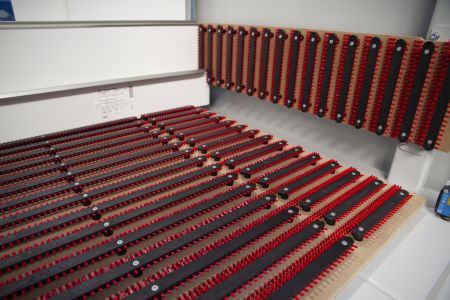

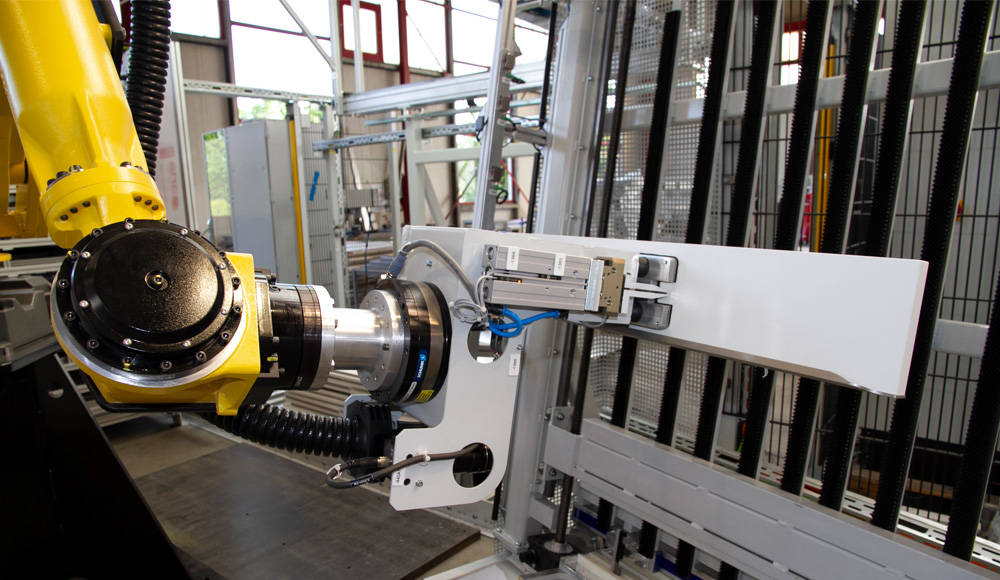

Automation of handle rail assembly for the furniture industry

Handle rail assembly is a crucial step in furniture manufacturing, as it has a major impact on both the function and appearance of the finished product. With automation solutions from Rotte, you ensure that every handle rail is precisely positioned, securely attached, and visually aligned to perfection. Our custom-developed systems take over the complete handle rail assembly process reliably, quickly, and with reproducible precision—regardless of material, profile, or furniture design. This increases process reliability, reduces error rates, and permanently relieves your production staff.