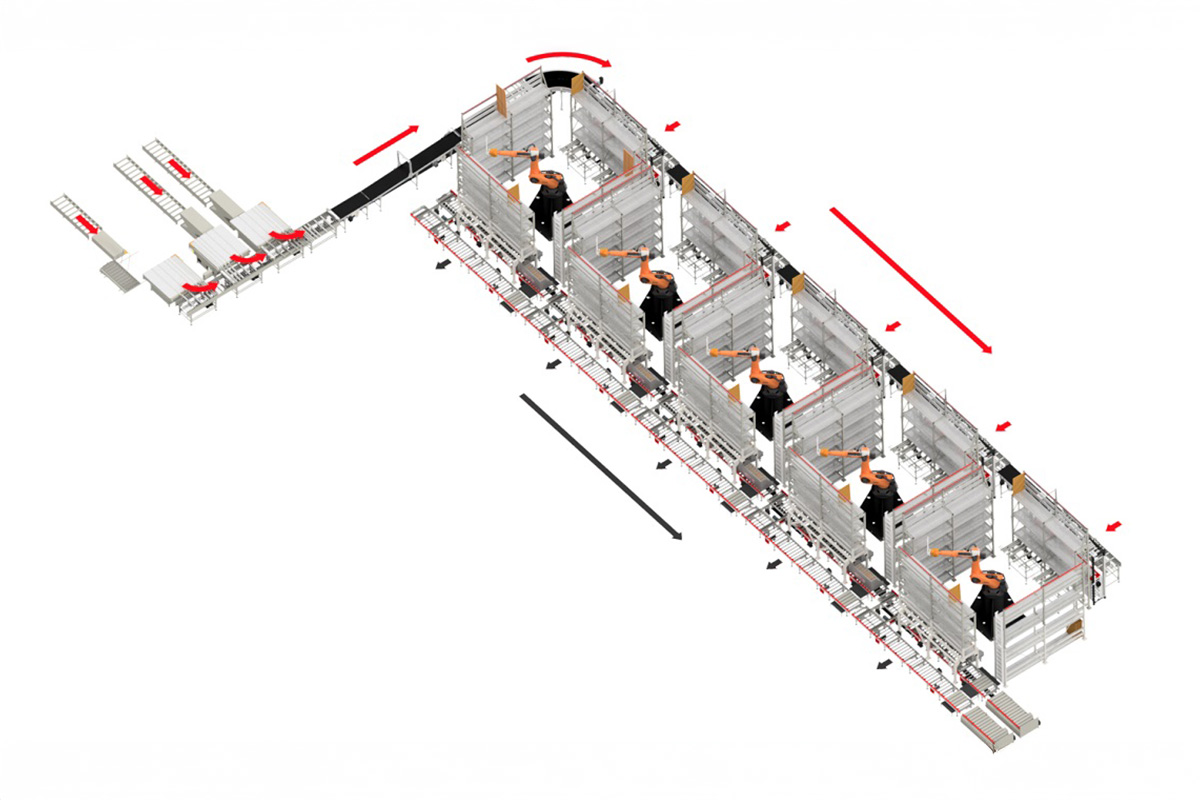

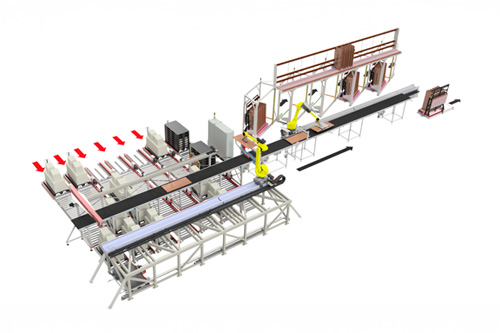

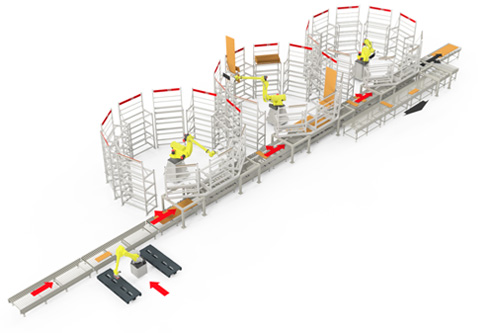

Flexible automation solutions for controlled material flow

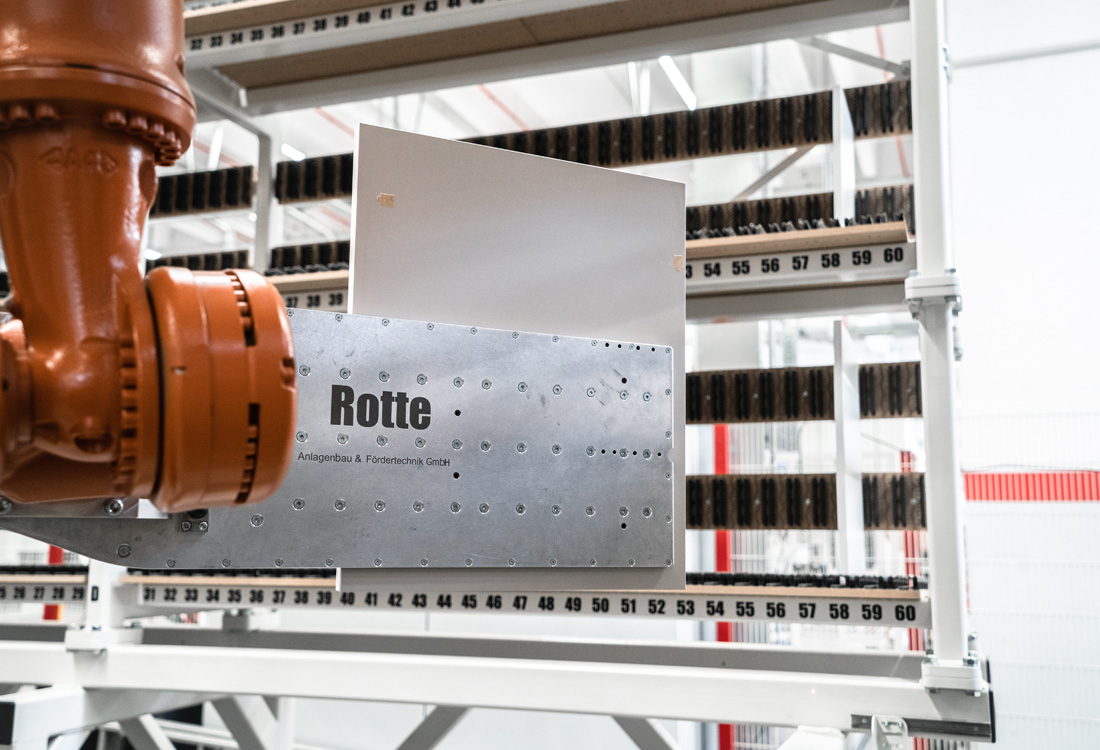

At Rotte, we offer intelligent solutions for maximum efficiency. In modern industry and logistics, automated sorting is a key factor in enabling efficient, error-free, and scalable processes. Today, companies must handle ever-larger product volumes in increasingly shorter timeframes—while staying flexible and reducing operating costs. This is where Rotte’s robotic sorting cells come into play. With innovative technologies, intelligent control systems, and custom-tailored solutions, we create sorting systems that optimize material flow and take your productivity to the next level.