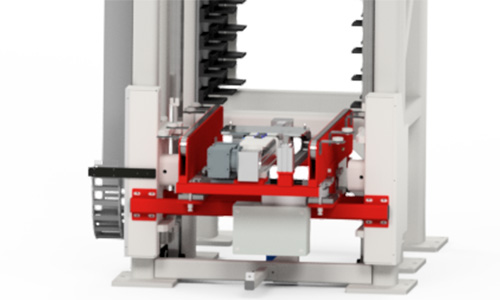

In high-output production processes involving multi-daylight presses, efficient storage and automation solutions are essential for maintaining smooth material flow. Only with precise pre-staging and post-handling of press tools and laminates can the full performance potential of the press system be realized.