Household Appliance Manufacturing

Automated Production of Household Appliances – with Special Machinery and Systems from Rotte

Washing machines, dishwashers, refrigerators, ovens—white goods and other household appliances are expected to perform better than ever before. Energy efficiency, durability, functionality, and design must be balanced with price pressure, short innovation cycles, and immense product variety. Manufacturers in the household appliance industry require custom-engineered systems that offer the flexibility to operate under highly variable production processes.

With our tailor-made automation solutions for large household appliance production, you’ll gain flexibility and efficiency advantages that give you a decisive competitive edge in your industry—from preassembly and handling to final inspection. Our systems combine robust engineering with intelligent control to ensure high cycle rates without compromising on quality.

Speak with our experts today about a customized special-purpose solution for your application!

Your contact person

Daniel Bürgermeister

Technical sales & project planning

Automated Systems for Household Appliance Manufacturing by Rotte

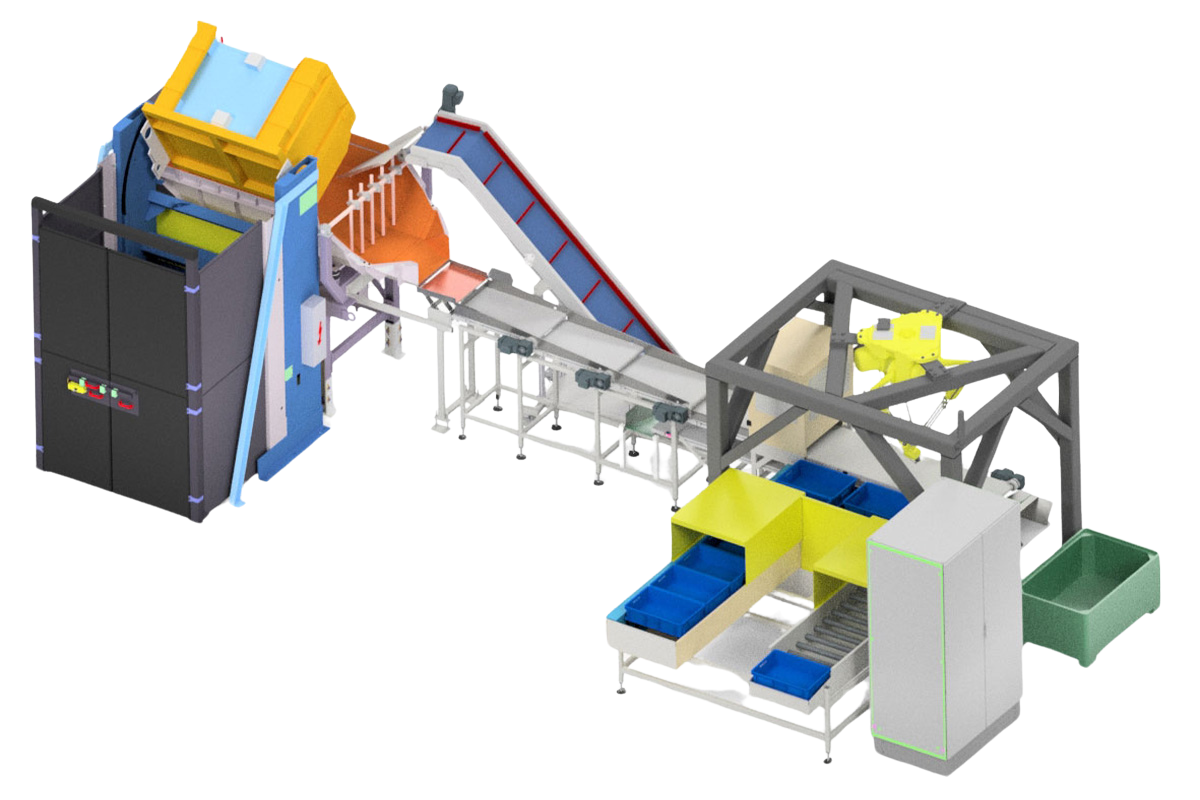

Producing household appliances involves a wide range of components, constantly changing models, and high unit volumes—all within tightly timed processes. With our custom-developed systems and solutions, we offer flexible technologies for every step in the production of washing machines, dryers, refrigerators, stoves, and dishwashers.

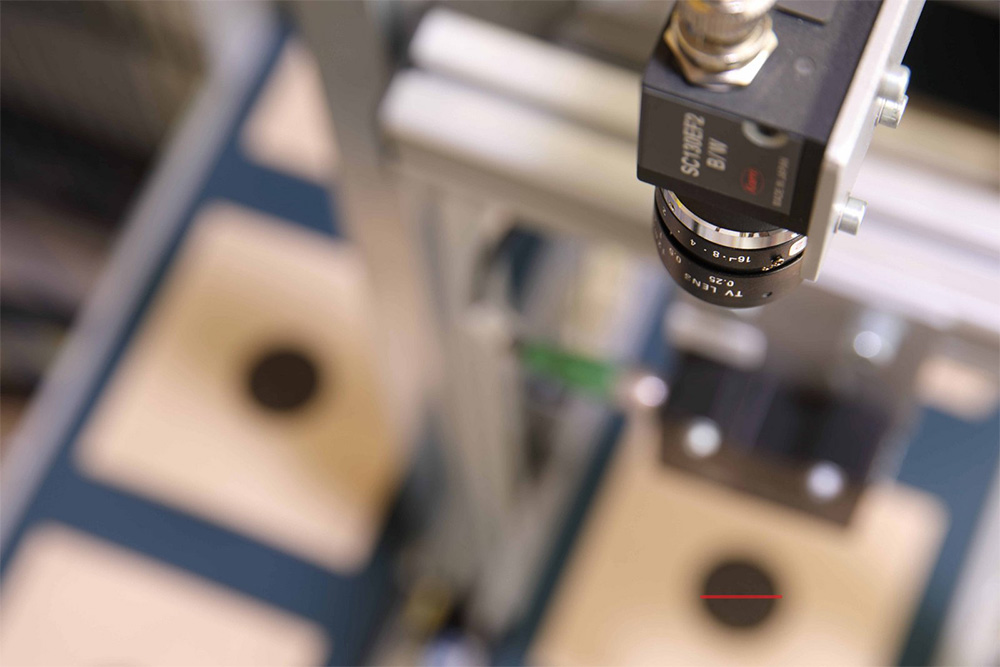

Our systems are designed to reliably withstand the demands of three-shift operations and can be quickly adapted to new product types or series changes thanks to their modular construction. Optional features such as vision systems with cutting-edge camera technology are available upon request.

Our solutions automate tasks such as:

- Parts feeding and singling of housings, drums, doors, controls, and assemblies

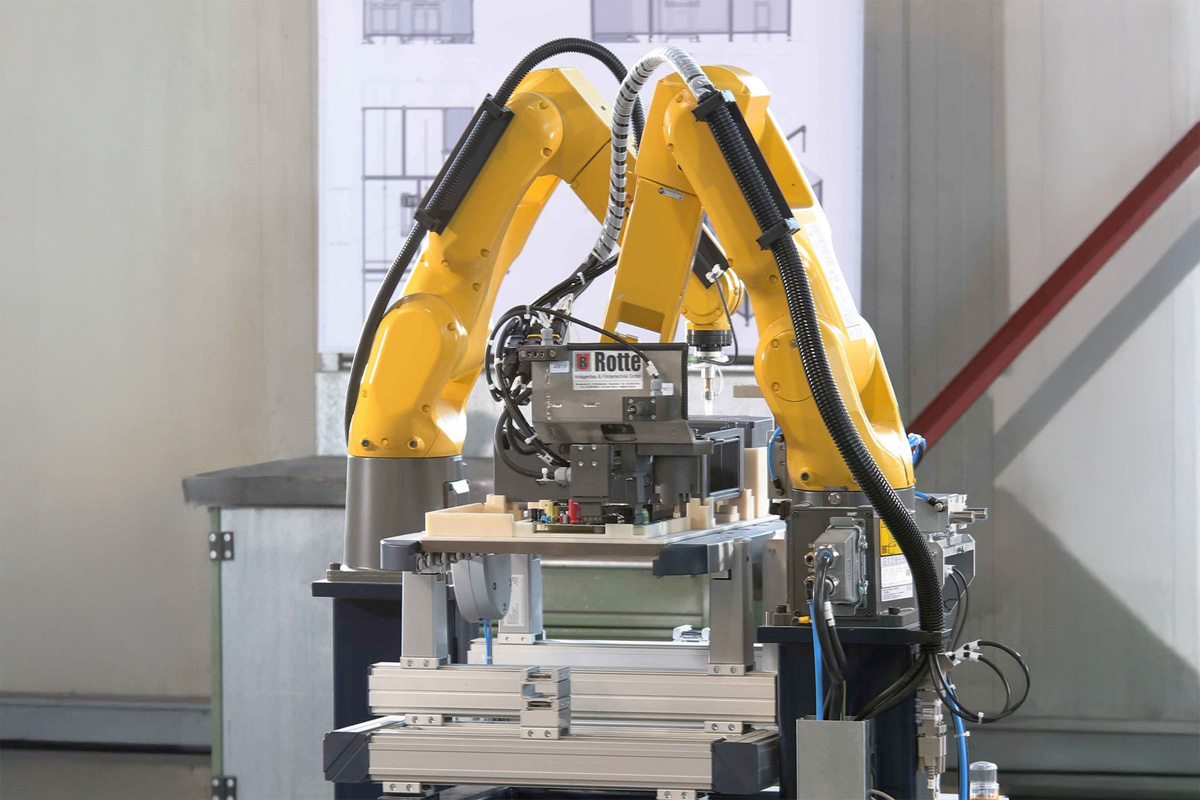

- Assembly processes for components like doors, control panels, seals, tanks, pumps for water or other fluids, and heat exchangers

- Screwing, gluing, and pressing of complex assemblies

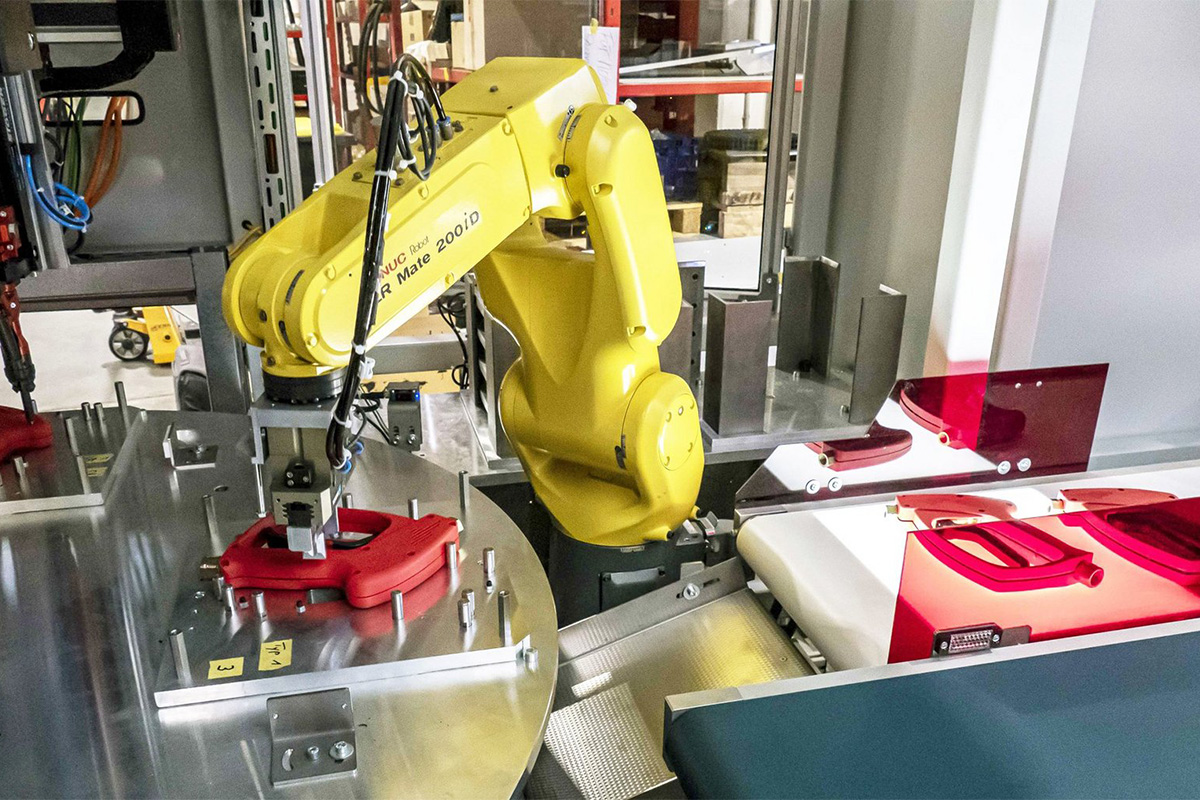

- Handling of large and heavy components using robust robotic and gantry systems

- End-of-line testing using advanced sensors and electrical diagnostics

From Development to Support – Full Expertise from a Single Source

Household appliance manufacturers increasingly rely on complete solutions that cover all process steps—from parts feeding to final packaging. As a general contractor, Rotte develops turnkey production systems tailored exactly to your requirements and production environment. We design your systems and automation solutions in close collaboration with your team—from the initial concept to final commissioning.

At Rotte, reliable engineering, process-oriented thinking, and flexible expansion options come together in one place. Get in touch with us today for a personal consultation!

Robotics & Vision Systems – For Intelligent, Variant-Ready Production

The wide variety of models in white goods requires manufacturing systems that can think on their feet. Robotics and industrial image processing are key elements of any modern production line.

Rotte integrates robust industrial robots and smart cobot solutions across a wide range of production processes—for example, for the automated insertion of drums, application of door seals, or handling of delicate control boards. Combined with vision systems, these installations can identify, align, and inspect components; detect errors and tolerance deviations; automatically distinguish between product variants; and dynamically adjust handling and assembly steps.

This enables a highly flexible and quality-assured manufacturing process that can easily adapt to changing component sizes or design variations—without the need for manual retooling.

One Company, Many Advantages

Ulrich Rotte Anlagenbau & Fördertechnik GmbH is your specialist in custom machinery. In addition to our innovative solutions in special-purpose machinery and automation technology, you also benefit from a wide range of customer and after-sales services:

Your Advantages at a Glance:

- Decades of experience in special-purpose machinery

- Extensive know-how across all areas of automation technology

- High expertise in the latest technologies and applications for Industry 4.0

- All services from a single source—from development and design to manufacturing, assembly, commissioning, and regular on-site maintenance

- Optional training of your machine operators, technicians, and supervisors at your facility

- Mechanical engineering made in Germany – we design and manufacture exclusively in Germany

- Personalized customer support – you will always have a qualified contact person available

Our products

Picking Robots

Robotic Order Picking: Efficient Automation for Precise and Flexible Logistics with Customized Picking Robots In ...

Automated Packaging Systems

Your Custom Packaging Line from Rotte As a manufacturer of automated packaging systems, we develop ...

Automated Punching

We manufacture your custom punching machine as a special solution High-precision punching of molded parts ...

Automated Assembly Systems

More productivity through customised assembly automation Increase the Efficiency of Your Production with Automation: The ...

In-Line and End-of-Line Testing

The implementation of automated End-of-Line (EOL) and In-Line testing systems enables companies to make their ...