Industrial Image Processing

Our Expertise for Automated Inspection and Quality Assurance

With modern industrial image processing, Rotte delivers intelligent automation solutions that go far beyond common industry standards. As an experienced specialist in custom robotic cells and systems, we integrate powerful camera systems directly into your production processes—creating the foundation for reliable quality control, precise position detection, and seamless traceability—automated, in real time, and tailored to your application.

Our strength lies in seamlessly combining robotics and modern camera technology into fully customized vision systems. Every solution from Rotte is built on deep process understanding, years of experience in special-purpose machine engineering, and strong technological innovation. Working closely with your team, we develop turnkey systems that deliver precision, speed, and efficiency through intelligent image processing—enhancing the reliability and performance of your production sustainably.

Contact us now to take your quality processes to a whole new level with industrial image processing!

Your contact person

Daniel Bürgermeister

Technical sales & project planning

Quality Control and Defect Detection:

Identifying dimensional deviations, defects, form errors, surface damage, or missing elements

Part Identification and Assignment:

Ensuring correct part feeding in assembly and packaging processes

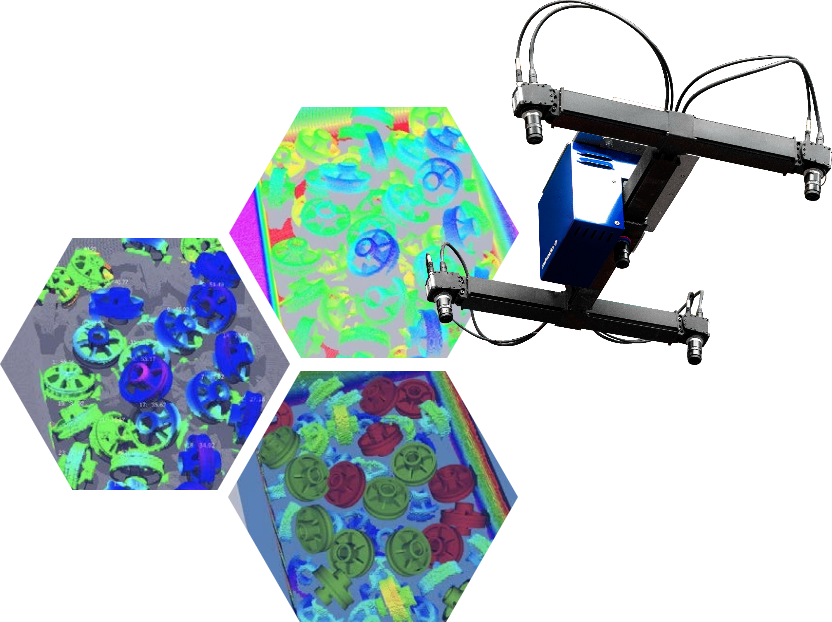

Position and Orientation Detection:

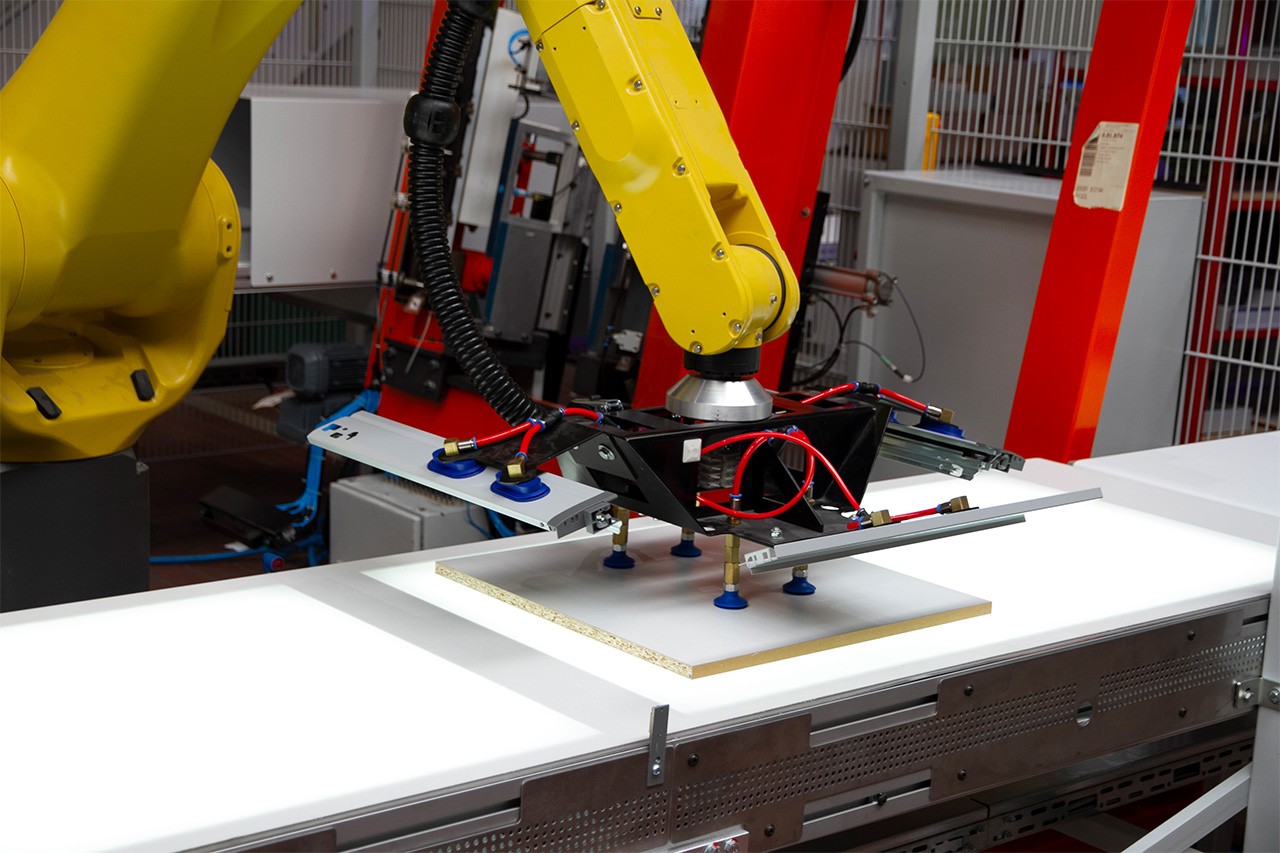

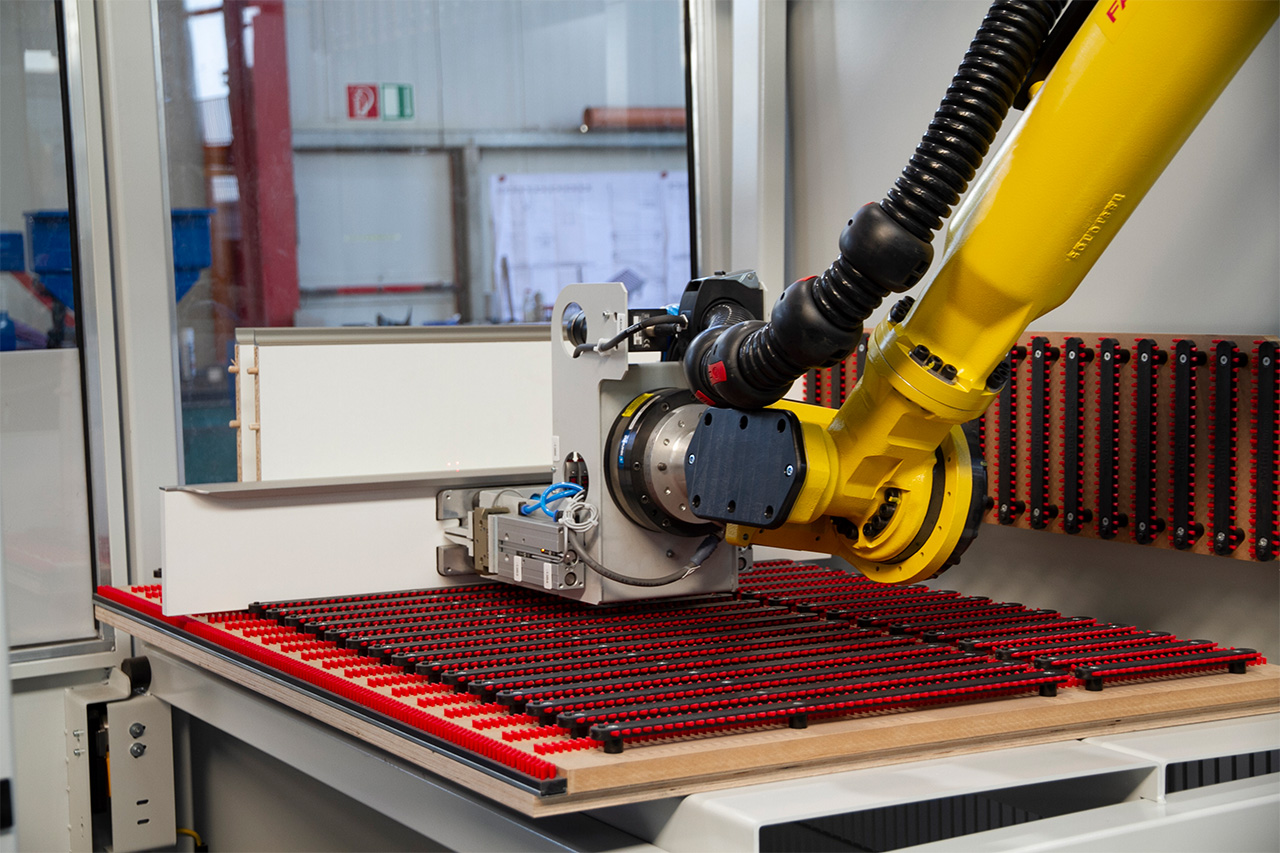

Locating components for precise robotic control (e.g., in pick-and-place operations)

Barcode and Data Matrix Capture:

Real-time traceability and documentation of production data

Optical Measurement:

Automated inline measurement of dimensions, angles, and tolerances

Industrial Image Processing – Intelligent, Innovative, Customized

Whether for visual inspection, part identification, position detection, or defect recognition—industrial image processing is a key element of modern manufacturing. By integrating high-performance camera systems and AI-assisted software, complex inspection tasks that once required time-consuming manual effort can now be automated.

At Rotte, image processing is an integral part of our automation and robotics solutions—perfectly adapted to your industry, your products, and your quality standards. Our systems are used in areas such as.

Depending on the task, we combine various technologies—2D or 3D cameras, color or thermographic systems, appropriate lighting, line or area sensors—along with custom-programmed analysis logic and seamless integration into your system controls. The result is application-specific automation that meets your exact needs down to the finest detail.

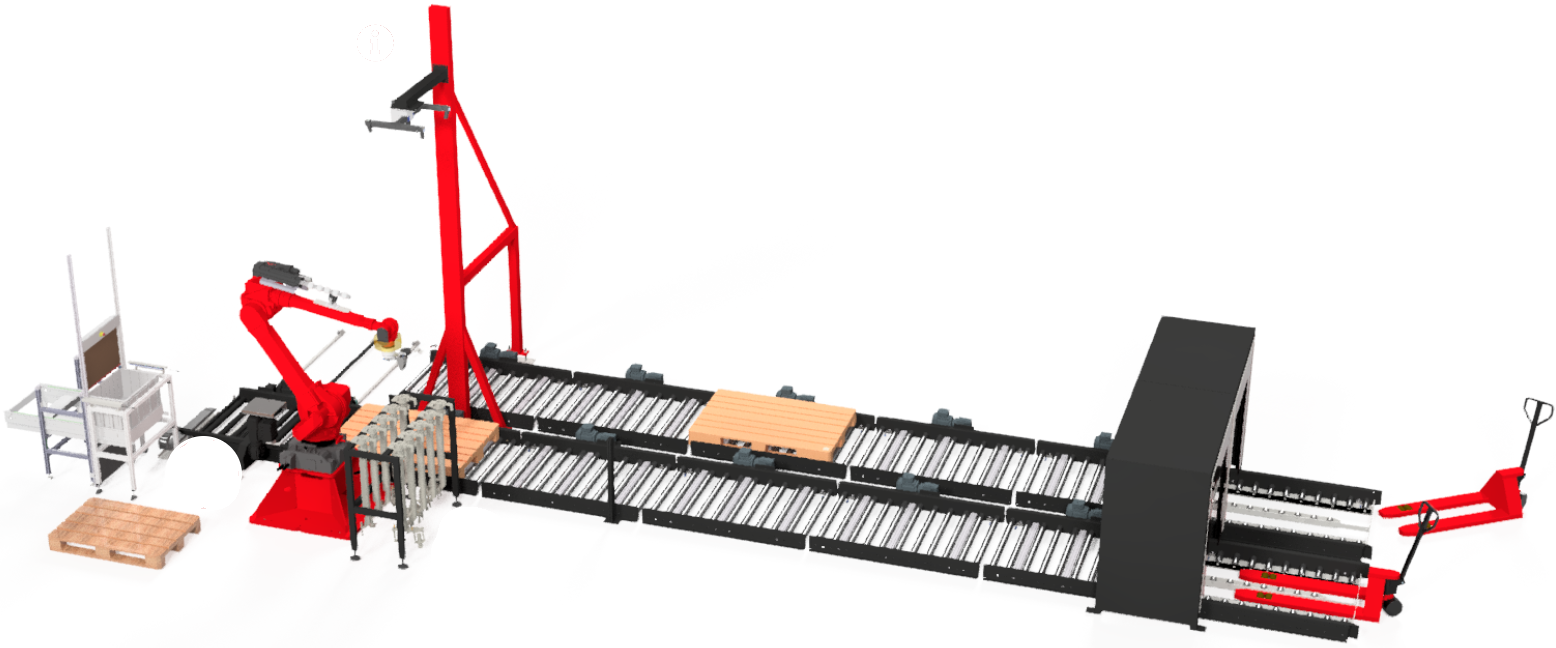

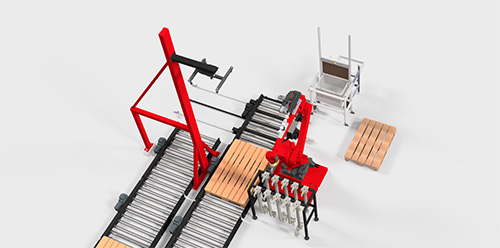

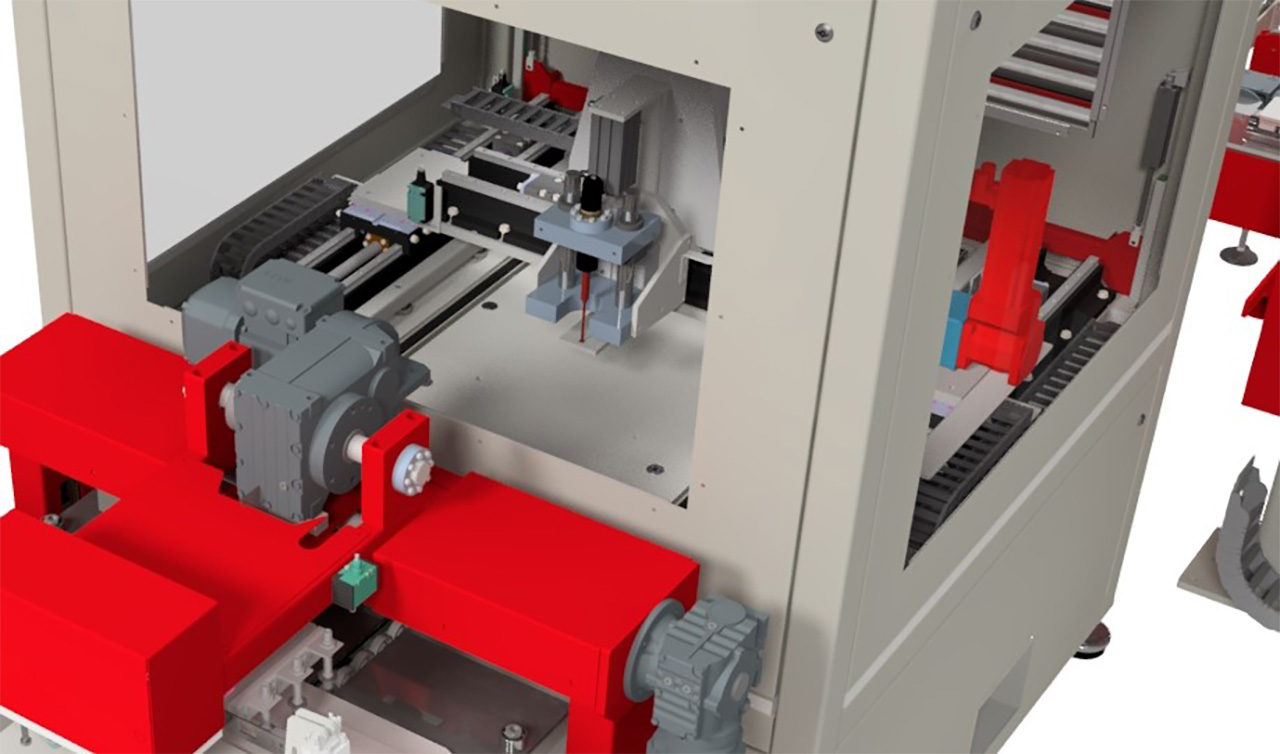

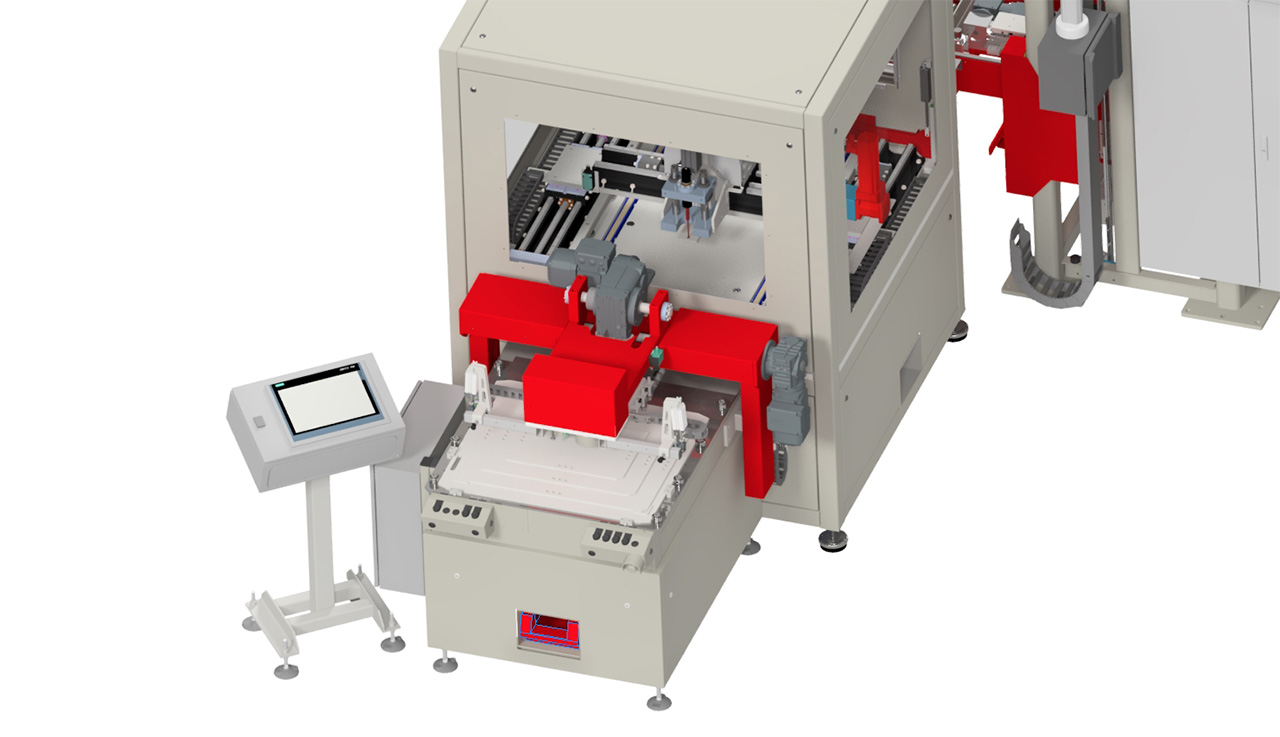

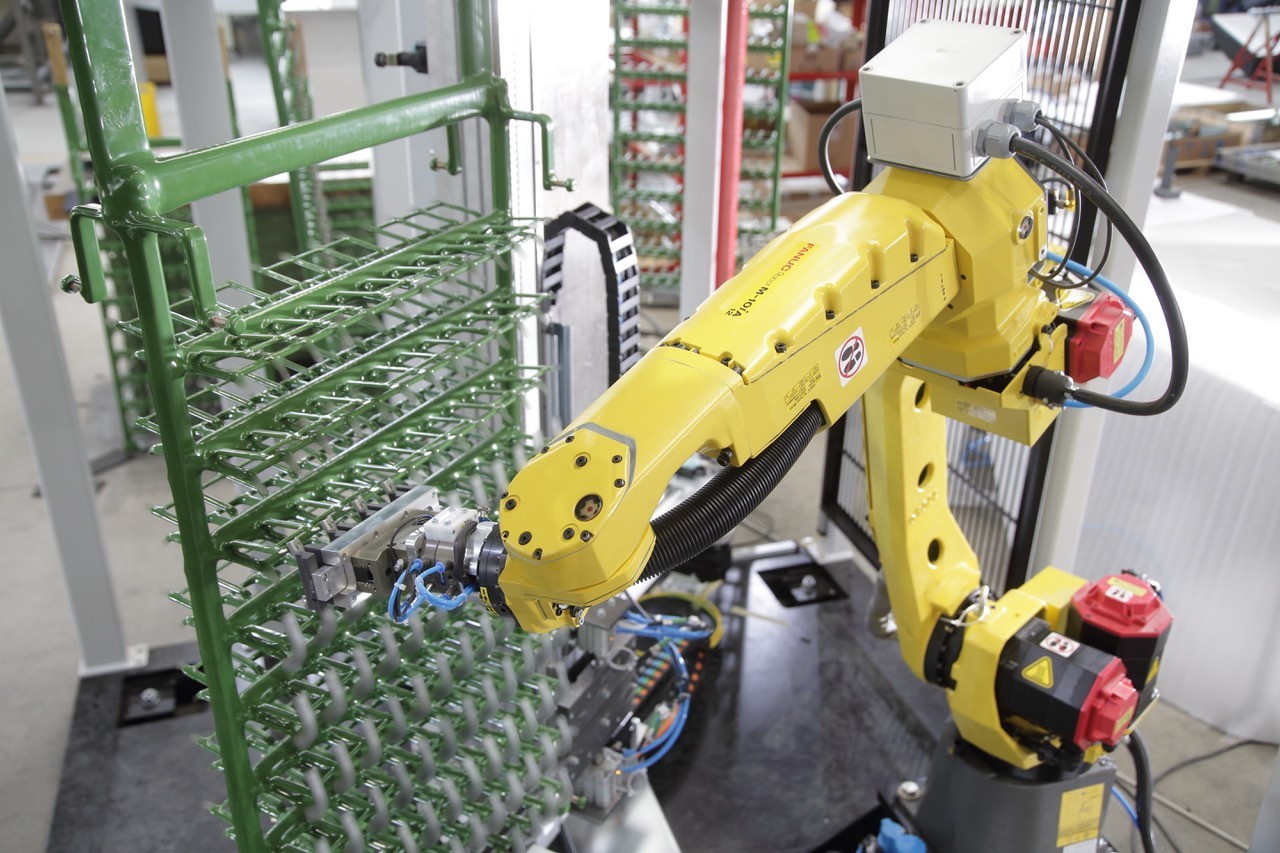

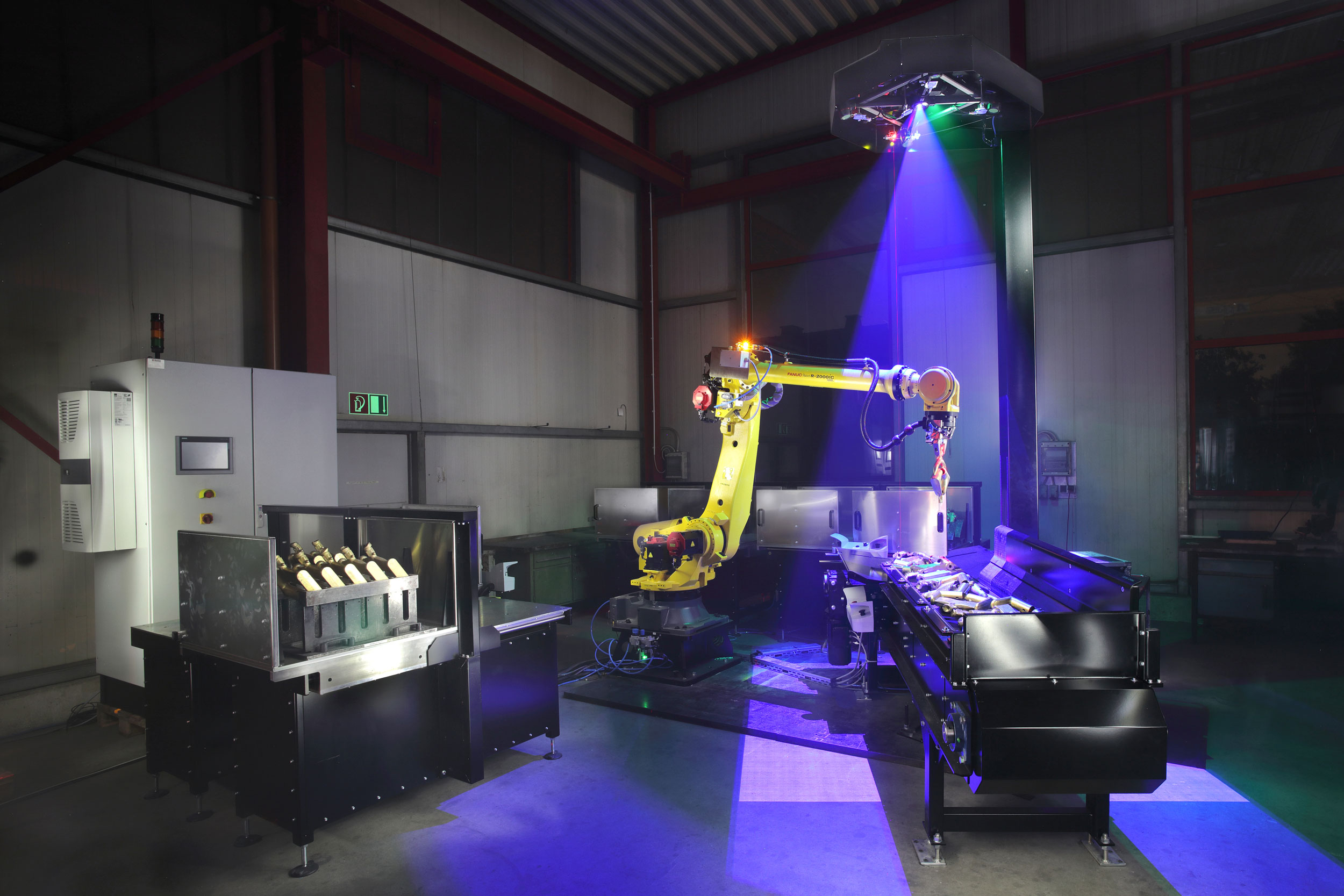

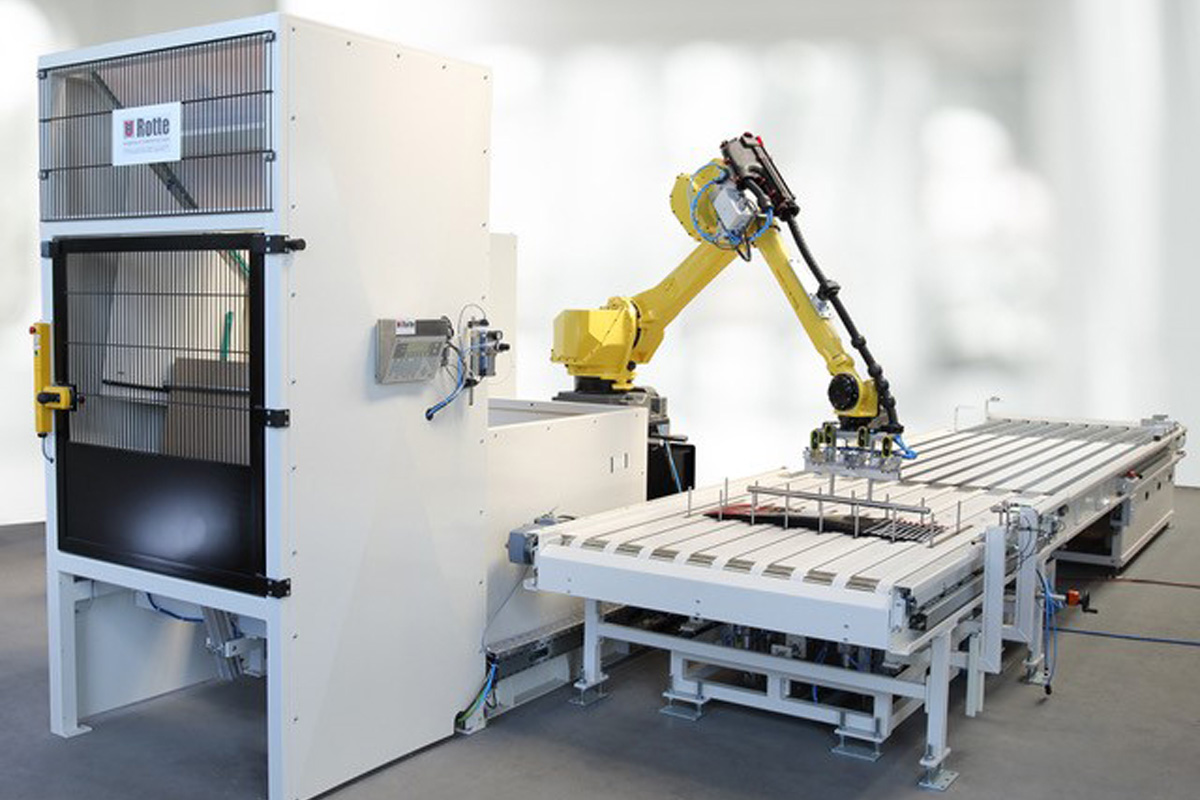

More Efficiency and Precision with Custom Robotic Cells

The combination of industrial image processing and robotics is one of Rotte’s core competencies. We develop complete robotic cells and systems in which camera systems not only handle inspection but also actively control robotic movements. This results in dynamic, self-learning systems that respond flexibly to product variations or inaccurate part positions—without retooling and at consistently high cycle rates.

Our robotic cells with integrated vision systems provide a powerful fusion of intelligent automation and precise quality assurance—custom-engineered and delivered from a single source. The process begins with a needs-based analysis and development phase, during which we closely assess your requirements and design a fully tailored, ready-to-run solution.

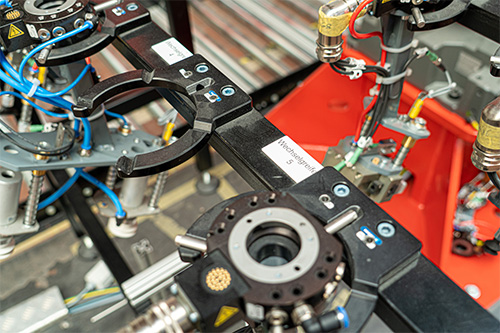

A central element is the integration of advanced industrial cameras and vision systems that are precisely aligned with your specific requirements. We handle the selection and configuration of both hardware and software, including application-specific algorithms—and, if desired, AI-assisted evaluation to reliably manage even complex applications.

Our systems ensure real-time communication between camera and robot control, enabling dynamic and accurate robot guidance for gripping, assembling, or sorting a wide variety of components. This is complemented by the mechanical design of the cell, including CE-compliant safety concepts and a user-friendly interface for easy and secure operation.

Whether you’re inspecting delicate surfaces, sorting complex parts, or automating flexible feeding systems—we’ll develop the right vision-based solution to deliver the highest levels of accuracy and reliability available on the market today. Industrial image processing ensures exceptional process stability and consistent product quality, even with small batch sizes and high variant diversity. By implementing image capture and digital data processing within production cells and manufacturing lines, you’ll immediately notice improved efficiency in your operations. Boost the productivity and profitability of your business now—with Rotte’s expertise.

Technology That Thinks Ahead – for Industry 4.0

Based on intelligent image processing, we create the foundation for adaptive, connected manufacturing processes. Our systems document and analyze data in real time, deliver quality-relevant insights directly to your control systems, and enable predictive maintenance or automatic process adjustments—in line with Smart Factory principles. No matter how carefully your staff work, industrial image processing technologies consistently outperform even the best human eye.

The range of applications is vast and spans nearly every industry. Whether automotive, food, electronics, medical technology, or plastics processing—image data analysis marks scalable progress across the board.

Take Advantage of Industrial Image Processing now – with Rotte

Your vision system should be as unique as your application. That’s why your technology partner needs to offer more than just a 3D camera. In today’s industrial image processing, full expertise in both hardware and software is essential—to reliably detect deviations outside of set tolerances, extract valuable data in real time, and enable ongoing improvements to efficiency and accuracy throughout your processes.

When combined with other technologies from Rotte—such as collaborative robots, modern control solutions, or automated conveyor systems—we create highly flexible production systems for a wide range of applications.

Take a closer look at our comprehensive product portfolio now and speak with us about how we can help prepare your manufacturing operation for the future of industry.

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationOne Company, Many Advantages

Ulrich Rotte Anlagenbau & Fördertechnik GmbH is your specialist in custom machinery. In addition to our innovative solutions in special-purpose machinery and automation technology, you also benefit from a wide range of customer and after-sales services:

Your Advantages at a Glance:

- Decades of experience in special-purpose machinery

- Extensive know-how across all areas of automation technology

- High expertise in the latest technologies and applications for Industry 4.0

- All services from a single source—from development and design to manufacturing, assembly, commissioning, and regular on-site maintenance

- Optional training of your machine operators, technicians, and supervisors at your facility

- Mechanical engineering made in Germany – we design and manufacture exclusively in Germany

- Personalized customer support – you will always have a qualified contact person available

Our products

Industrial Measurement Technology & Automation

Customized Measurement Systems for Your Business Precision measurement technology is a fundamental component of modern ...

Lay-up station

Smart material supply for technical laminates and panels with Lay-up Stations from Rotte. In the ...

Flipping-Stations

Flipping material—without compromising quality or cycle time Whether for preparing lamination processes, two-sided processing, or ...

Automated De-Pinning

Rotte De-Pinners for technical laminates, panels, and more In the production of technical laminates, panels, ...

Breakdown Stations

Customized Breakdown Stations for your requirements Rotte designs tailored breakdown solutions precisely matched to your ...

Automated Drawer Assembly

Robotic solutions for drawer assembly in the furniture industry In furniture manufacturing, precision is key—especially ...

Automated Handle Rail Assembly

Automation of handle rail assembly for the furniture industry Handle rail assembly is a crucial ...

Automatic Rack Loading Systems

Efficient, safe, precise: Automated rack loading with system Whether powder-coated components, painted workpieces, or heat-treated ...

Bin Picking Zelle CAMGripX-1200

Precise and reliable Bin Picking In modern industrial production, every second counts. Companies are increasingly ...

Bag and Pouch Packaging Machine

Efficient and Flexible Packaging Solutions Rotte develops fully customized packaging machines for pre-made bags and ...