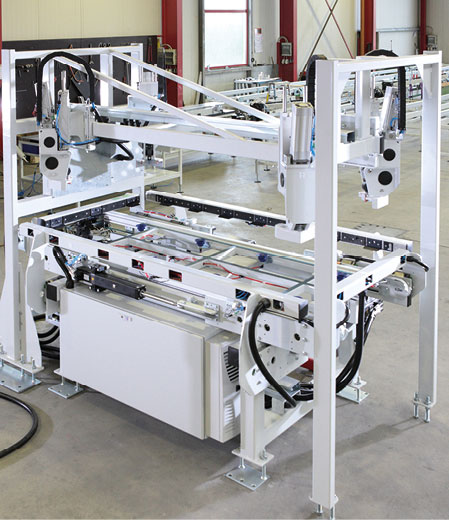

- PV modules frame and crimping in one station

- Unhindered insertion of the frame parts

- Automatic frame with powerful servo motors for high accuracy

- Sensitive displacement force monitoring, presettable

- Strong connection due to high crimping force

- Compact and robust design for efficient production

- With frame pre-assembly: press in 2 corner brackets in 1 operation, siliconize

Description:

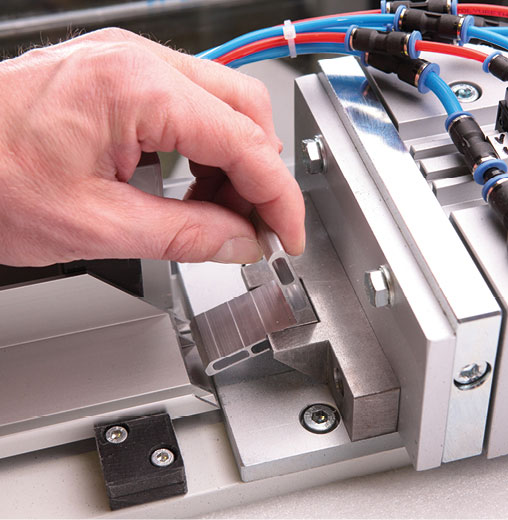

Corner angle pre-assembly, siliconizing, inserting frame parts, frame and optional crimping at one workstation: the activities are cost-effectively divided between operator and machine. While the framing unit feeds and positions the next laminate, the operator prepares the frame parts at the pre-assembly station. Simply insert the frame corners and short frame part into the device, close the protective hood and the corners are automatically crimped. The finished part can be removed immediately. For quick siliconization the frame parts are always held in the same position. Conveniently arranged storage surfaces and tool holders facilitate the work flow. The operator can fully concentrate on his work. The compact machine design allows free access for inserting the frame parts when working in short distances. The operator can insert the frame parts unhindered. The holders help him to position them easily and correctly and hold the frame parts in the correct position. Long frame parts with excess length cannot be inserted and can be sorted out. At the two-hand control, the operator monitors how the servo motors automatically push the frame parts onto the laminate. The displacement force monitoring system moves precisely to the specified frame dimensions and ensures high production accuracy. In case of faulty parts, the force monitoring stops the movement. The operator can react directly and flexibly and repeat the process as often as required. 4 corners can optionally be crimped directly after the frame. With the inline or offline version for 1 or convertible to several module sizes, the framing/crimping can be flexibly integrated into your production.