- Direct delivery of the products to be stacked by an upstream production system

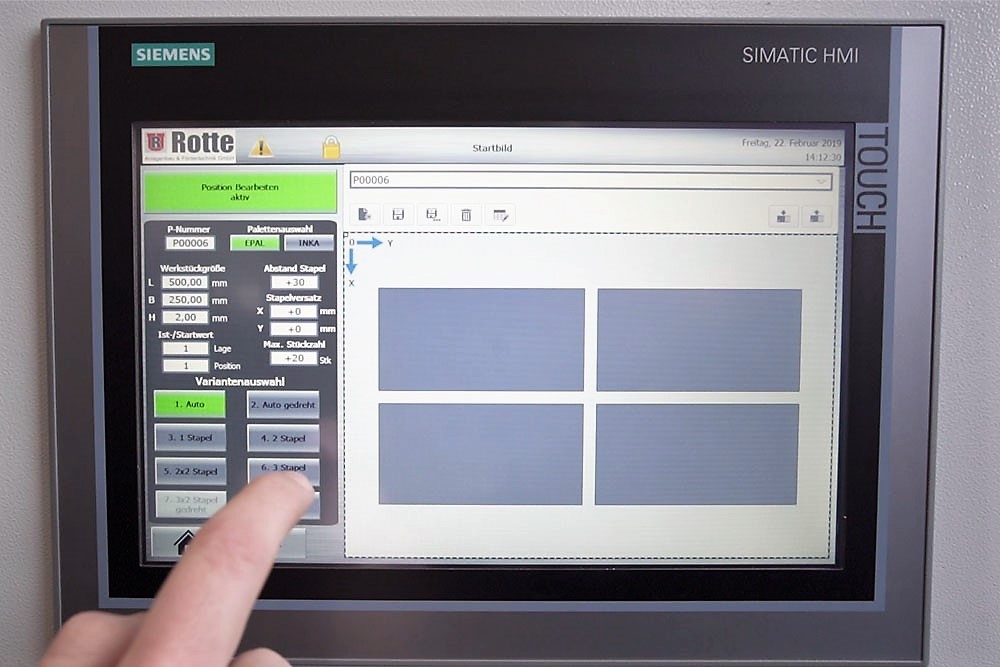

- Simple creation of new products without the operator needing any programming skills

- Flexible stacking of different products and packing patterns on one pallet

- Automatic selection of the correct gripper according to the product size using the quick-change system

- Creating, saving and modifying product-specific packing patterns in an intuitive manner directly on the HMI

Description:

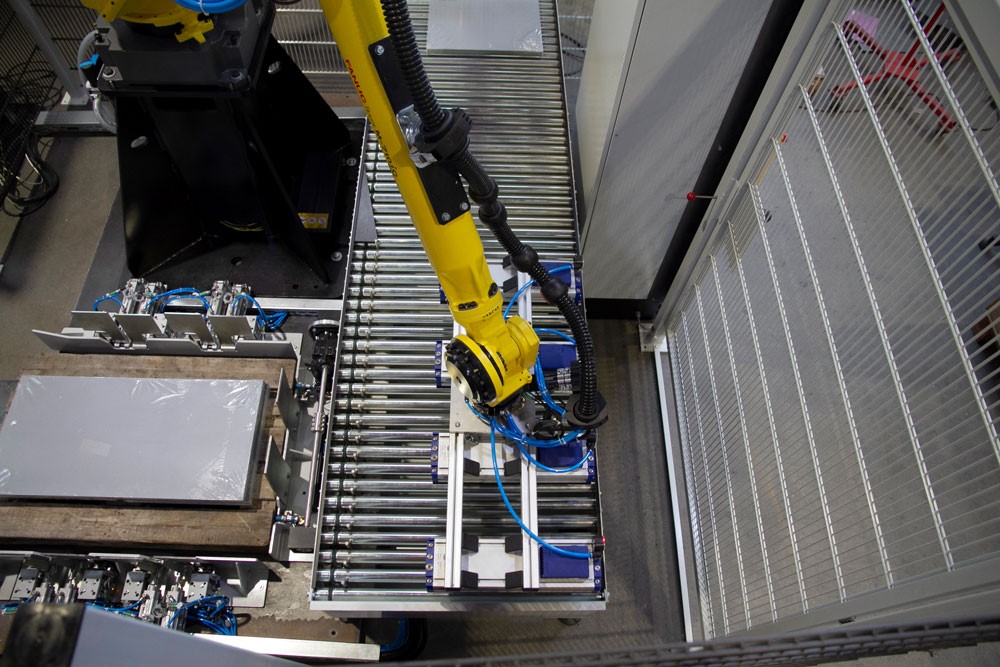

The stacking robot with automatic generation of packing patterns is the perfect solution for stacking products with a great variety of types neatly and orderly on pallets according to customer-specific packing patterns.

The system can, for example, be positioned directly behind a packing machine and if required be fitted with a unit for orienting the products. In the ideal case, the product dimensions will be transferred directly to the system; however, manual input of the dimension using the HMI is also possible. Based on the product size, the system automatically calculates the start-up position for the robot and the stacking position on the pallet. Selection of an appropriate gripper is also done automatically within a few seconds using a quick-change system. This means that there is no need to teach the robot in case of new products.

The automatic packing pattern generation guides operators during the initial creation of a packing pattern which can then be stored and automatically retrieved for each product. Furthermore, it is also possible to flexibly adjust packing patterns based on the individual order.

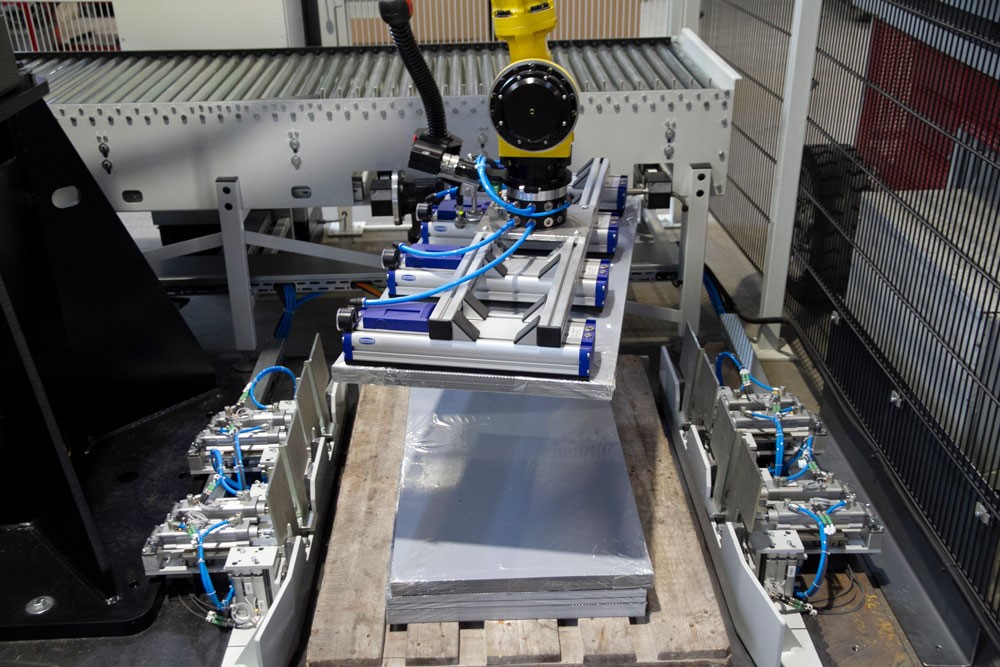

The grippers are individually adjusted to the products. Whenever possible, vacuum suction grippers are used to move planar products; it is, however, also possible to use mechanical grippers.

Typical use cases are, for example, stacking of

- Products in cardboard packaging (e.g. electrical appliances, beverages, etc.)

- Products in (shrink) wrapping (e.g. printed matter, panels, etc.)

- Sheet products (e.g. furniture parts, wood, concrete slabs, etc.)

![[Translate to English:] [Translate to English:] Packlagengenerierung mit Roboter und Greifersystem anhand von Bildverarbeitung](/fileadmin/Seiteninhalt/Bilder/Produkte/Robotertechnologie/packlagen8.jpg)

![[Translate to English:] [Translate to English:] Stapelautomation](/fileadmin/_processed_/6/d/csm_packlagen7_968c4618c5.jpg)