- Batches of different Shore hardness are cut according to the mixture recipe

- Equipped with a rotating blade and adjustable counter knife

- Max. three layers of skins can be cut at the same time

- Sensory monitoring of the cutting chamber

- Top belt ensures even conveyance

Description:

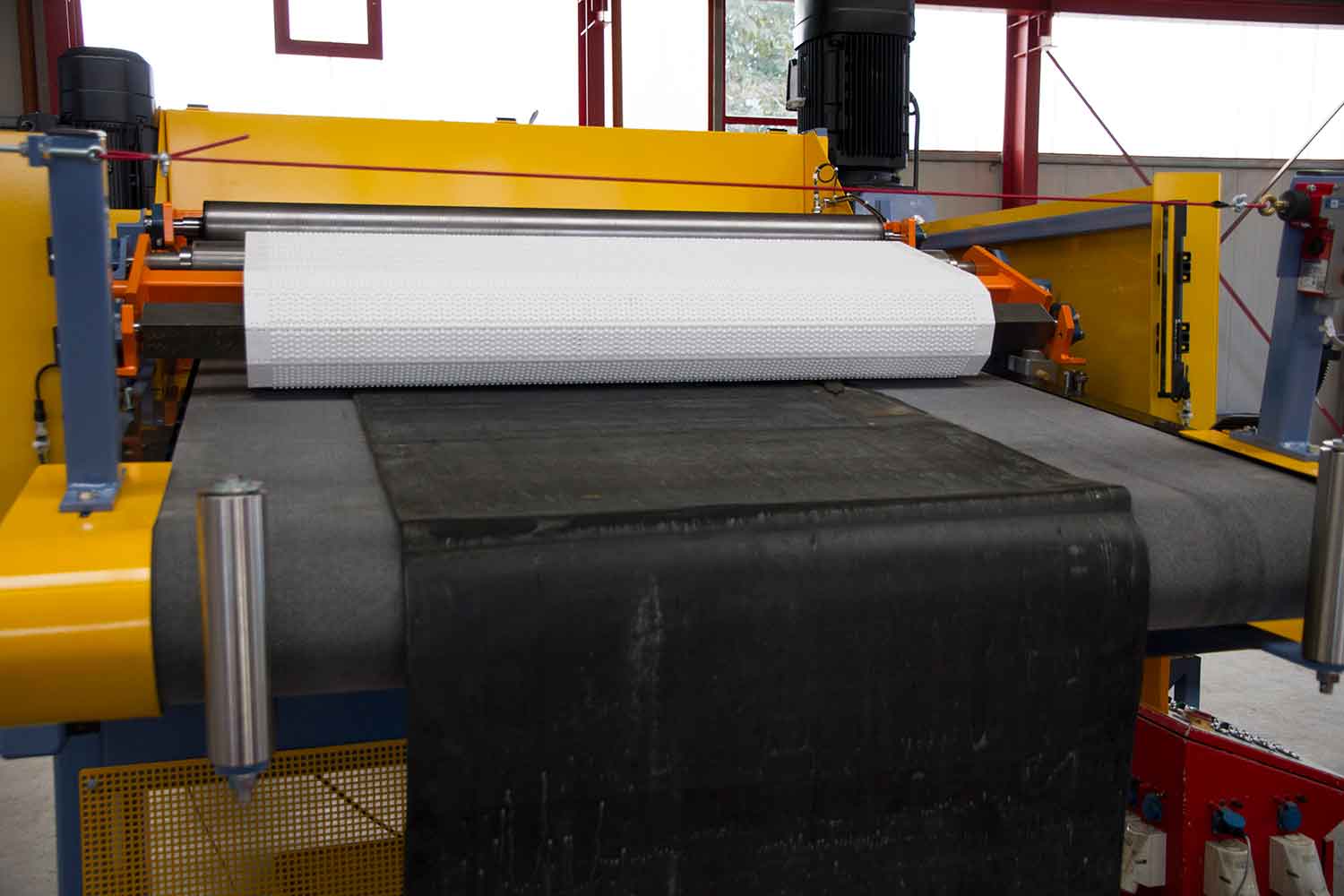

The batch feeder for the mixing room consists primarily of an attached cutting unit and a feed conveyer. The skins are manually fed to the conveyor belt. A cover belt ensures that the batch enters the cutting process evenly. The skin is then conveyed through the cutting chamber, which is monitored sensorially. The skin is placed and weighed in a loop on the customer's integrated or existing weighing belt. When the desired weight is reached, the cutting unit is triggered. Up to three skins with a total maximum thickness of 36 mm can be processed simultaneously. The batch feeder is equipped with a fixed cutting head. At the customer's request, the feeder can be equipped with a movable cutting head so that two mixing lines can be supplied.