Conveyor Technology

Our custom conveyor technology for industry advances your production and intralogistics significantly!

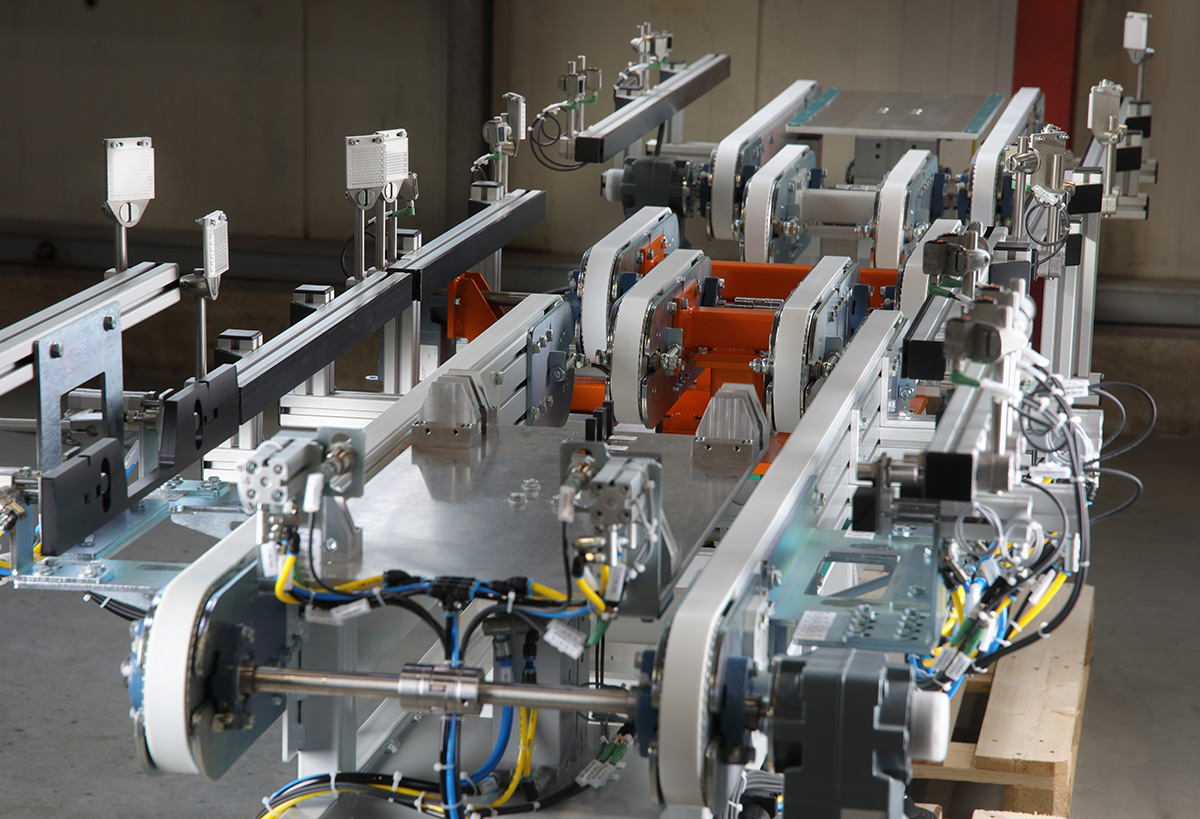

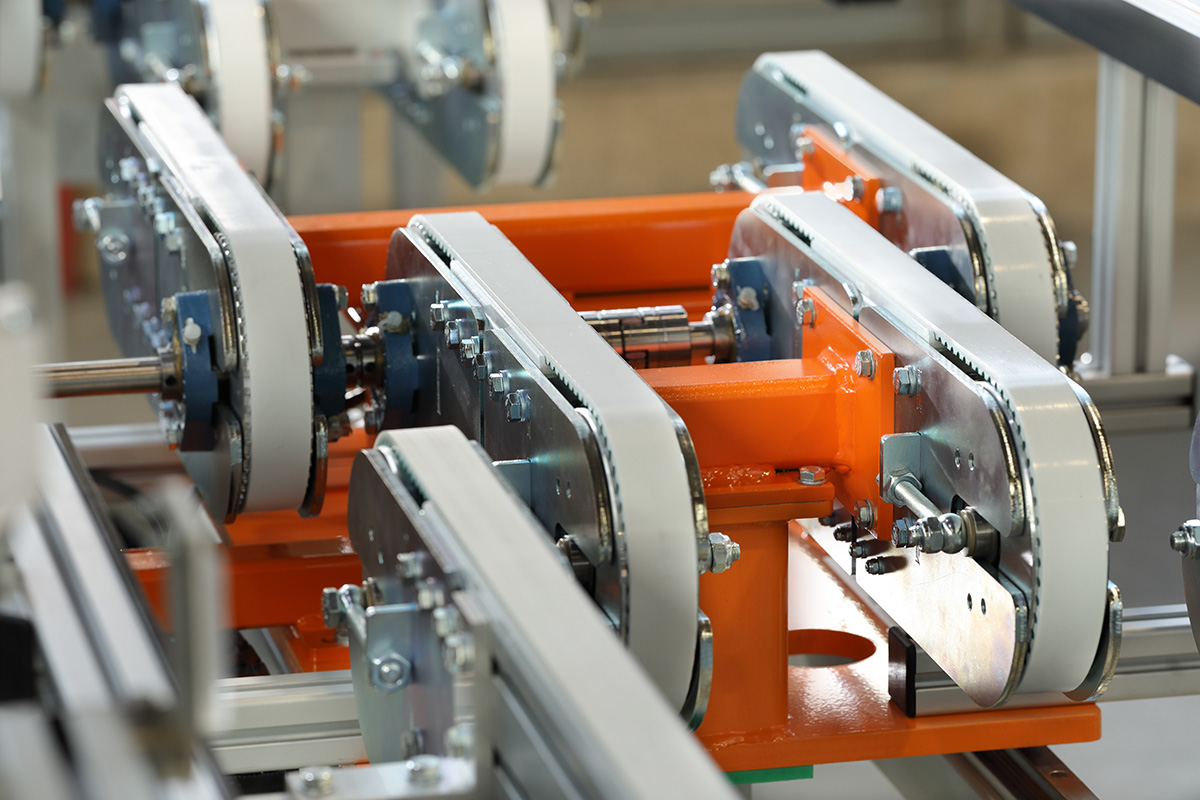

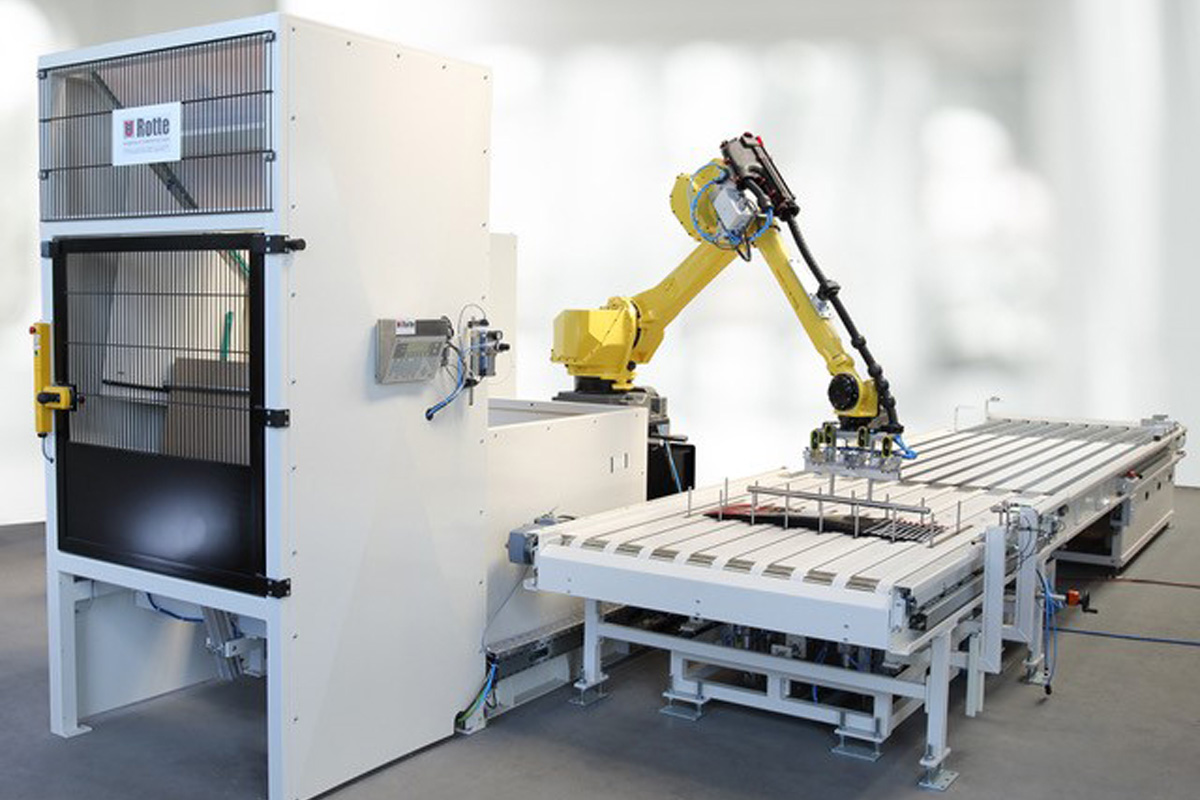

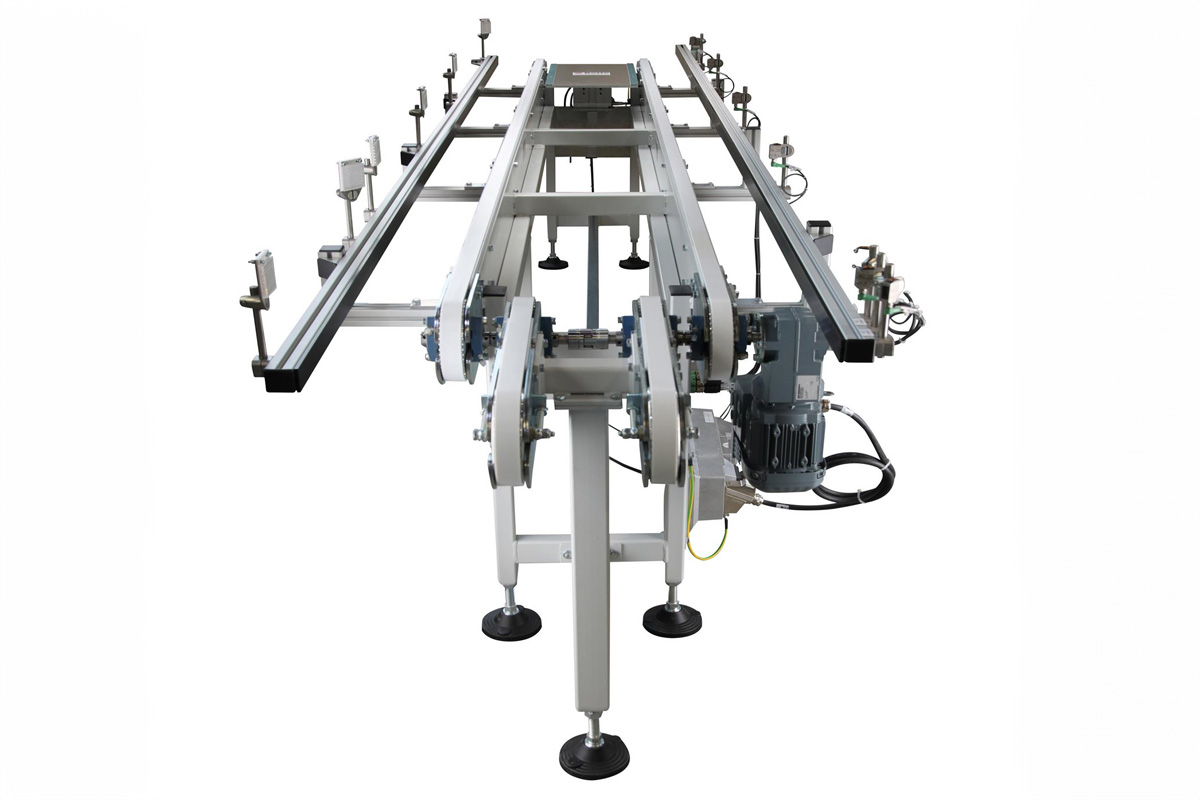

Conveyor technology is one of our core competencies. Individually built and tailored to spatial conditions as well as aesthetic preferences. Our conveyor systems are made from solid, durable frames. The modular design provides flexibility and long-term expansion possibilities. Elevators, various lifters, lifts, or lifting stations can be integrated into the conveyor line to bridge paths. Incorporation of rotating stations, corner transfer units, centering stations, and the pick-up and hand-off with movable/active conveyors is possible. We also handle necessary programming in connection with control system construction and the networking of third-party machinery with Rotte conveyor technology.

Your contact person

Daniel Bürgermeister

Technical sales & project planning

Customized Conveyor Systems for Smooth Material Flow

Modern conveyor technology does more than simply transport goods from A to B. It’s a central component of efficient production processes and logistics systems. Our conveyor solutions are designed to seamlessly integrate into your existing operations, helping to optimize material flows, shorten process times, and use resources more efficiently. You have a choice from all available technical options: belt conveyors, chain conveyors, and timing belt conveyors, vertical conveyors, and integration into various production lines—all possible even in environments with low or high temperatures. We welcome your challenges!

Whether heavy loads, delicate components, or small parts, we offer the right technology for every application area. We take into account the individually planned transport paths and conveyor speeds, factors like ergonomics, safety requirements, and energy efficiency.

Conveyor Systems 4.0 – Intelligent Solutions for Tomorrow’s Industry

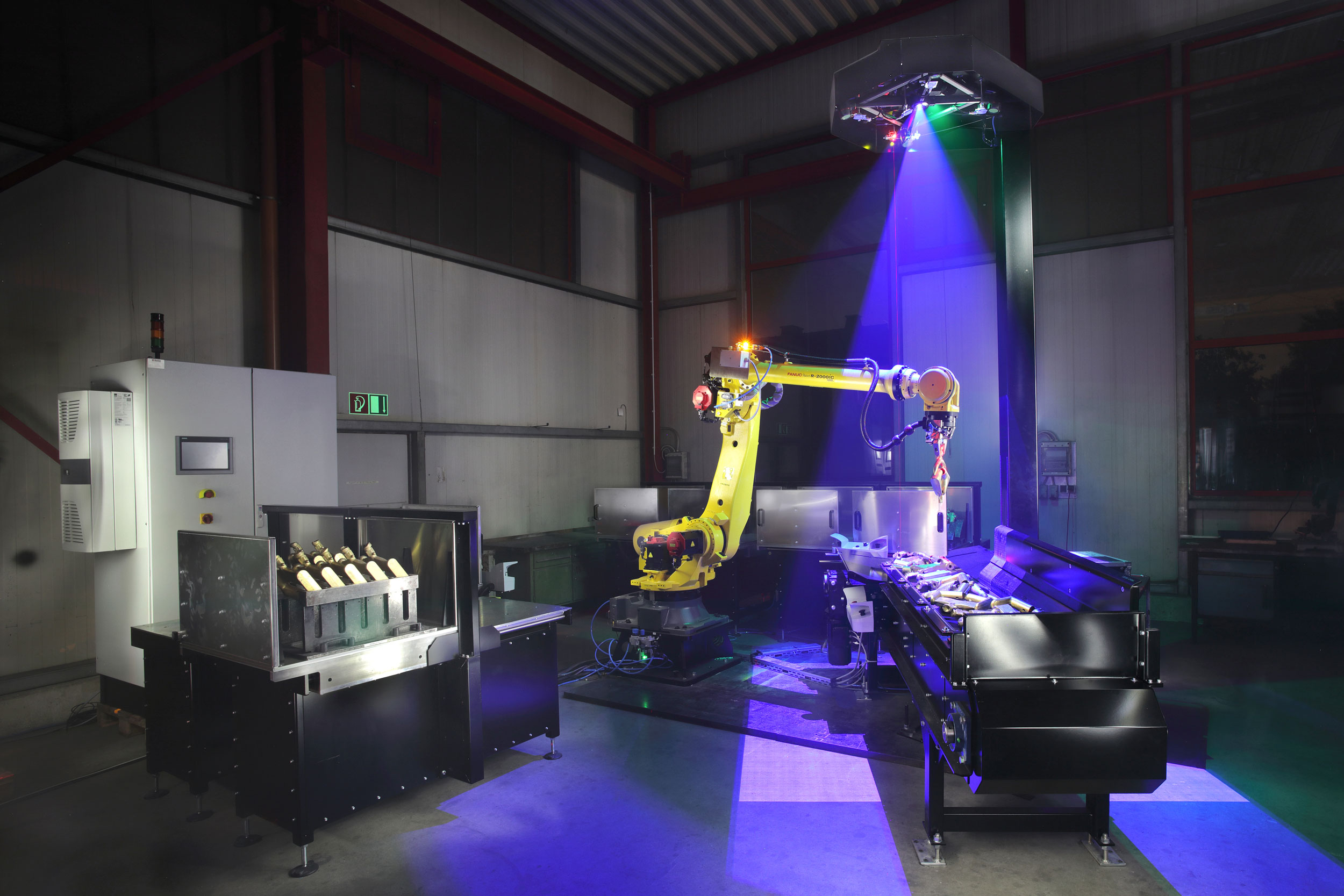

Digitization does not stop at conveyor technology. At Ulrich Rotte, we rely on intelligent automation technologies to make your conveyor systems more efficient and flexible. Through the use of sensors, IoT integration, and modern control systems, our systems can be integrated into existing production networks and monitored in real time.

This enables you to optimize material flow, reduce downtime, and plan maintenance proactively. In conjunction with solutions such as camera systems for optical monitoring, our systems detect deviations in operation early and enable predictive maintenance, preventing costly downtime. With your intelligent Rotte conveyor system, you transport goods and items more reliably and quickly, while also relieving your human employees.

With our expertise, your conveyor technology consistently moves towards the future. We are developers, manufacturers, and implementers of tailor-made solutions for your product range and your success. Talk to us!

Efficiency and Sustainability through Effective Automation

Sustainability is an integral part of our development philosophy. Our conveyor systems are designed to operate as energy-efficiently as possible while simultaneously ensuring high performance. By using efficient energy-saving drive systems and intelligent control, our systems actively contribute to reducing your ecological footprint. We rely on robust, durable, and low-maintenance components to conserve resources and permanently reduce operating costs.

From roller conveyors to the digitized control unit, each of our high-quality conveyor systems is designed to optimally support your internal processes. For us, this means saving not only time but also valuable resources, ensuring that your requirements for economy, sustainability, and compliance are always fully met.

One Company, Many Advantages

Ulrich Rotte Anlagenbau & Fördertechnik GmbH is your specialist in custom machinery. In addition to our innovative solutions in special-purpose machinery and automation technology, you also benefit from a wide range of customer and after-sales services:

Your Advantages at a Glance:

- Decades of experience in special-purpose machinery

- Extensive know-how across all areas of automation technology

- High expertise in the latest technologies and applications for Industry 4.0

- All services from a single source—from development and design to manufacturing, assembly, commissioning, and regular on-site maintenance

- Optional training of your machine operators, technicians, and supervisors at your facility

- Mechanical engineering made in Germany – we design and manufacture exclusively in Germany

- Personalized customer support – you will always have a qualified contact person available

Our products

Bin Picking Zelle CAMGripX-1200

Precise and reliable Bin Picking In modern industrial production, every second counts. Companies are increasingly ...

Bag and Pouch Packaging Machine

Efficient and Flexible Packaging Solutions Rotte develops fully customized packaging machines for pre-made bags and ...

Automated Storage Systems for Multi-Daylight Presses

Perfect handling starts with the right gripper In high-output production processes involving multi-daylight presses, efficient ...

Automatic Pallet Magazine

Effortless Stacking and Destacking with Variable Capacity Efficient solutions for the automatic stacking and separation ...

Belt Conveyors

Custom Conveyor Solutions for Your Production Efficient material flow is essential in modern production and ...

Drum Turner

When Everything Revolves Around Your Workpieces Turners for panels of all material types: In many ...

Thermoforming Machine

Precision meets innovation – thermoforming technology for demanding fibre materials For the industrial processing of ...

Loading and Stacking Robots

Smart Automation for Precise and Efficient Stacking In today’s industrial environments—with their complex production and ...

Heavy-Duty Roller Conveyors

Heavy-duty roller conveyors from Rotte are an optional yet integral component of our complete solutions ...

Picking Robots

Robotic Order Picking: Efficient Automation for Precise and Flexible Logistics with Customized Picking Robots In ...