- Smart picking according to production sequence, e.g. in trolleys or picking carts

- Single compartment access eliminates need for resorting

- Separating component stacks to pallets with undefined content and status report

- Intermediate buffer for separation

- Careful handling of the components

- Guaranteeing the correct compartment allocation and component orientation for the subsequent process

Description:

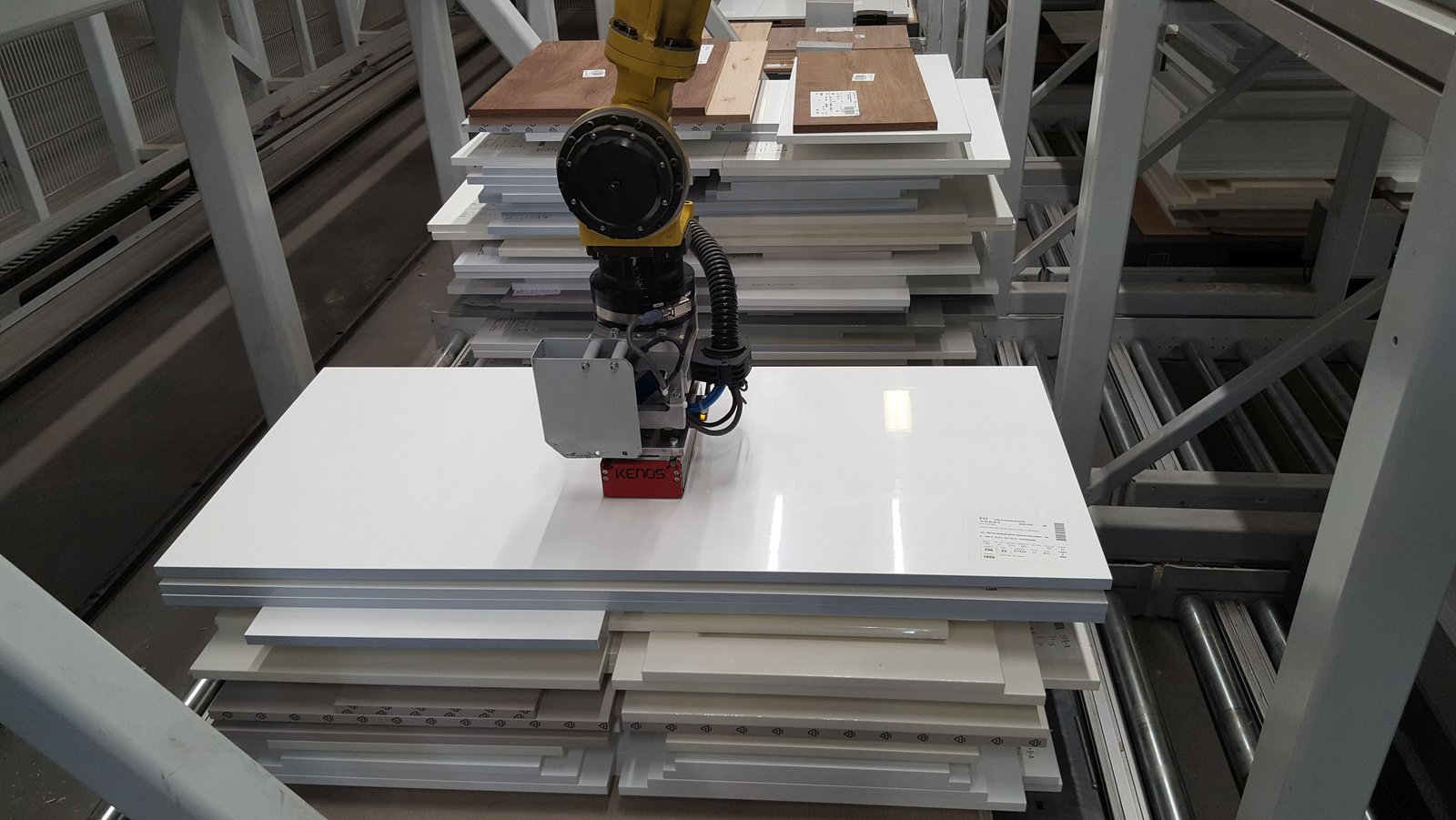

The system for picking planar components is divided into an unstacking and a picking section.

The unstacking section is fed manually or automatically with pre-picked stacks in a sorted or unsorted order. The high buffer quality is ensured by several conveying lanes. Empty pallets are stacked and then returned. A separate manual sorting process is not required when setting up your batch sizes for picking on pallets – irrespective of whether you pack, for example, country style, lacquered or veneer fronts on a pallet.

In the next step after unstacking a line scan camera accurately measures the position and size of all separated or manually fed components, and a bar code/QR code reader identifies them again. This plausibility check allows incorrectly labeled components to be stored in an out-of-order area within the system. Irrespective of their orientation, left or right doors, curved country-style fronts or components with handle recesses are stored at predefined storage positions according to your individual specifications. An intermediary buffer is therefore a suitable alternative if, for example, the correct picking trolley has yet not been registered.

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/3/2/csm_Burger__160236_mit_Pfeilen_komprimiert_f8d9255386.png)

![[Translate to English:] [Translate to English:] Roboterautomatisiertes kommissionieren in der Möbelindustrie](/fileadmin/Seiteninhalt/Bilder/Produkte/Moebelindustrie/kommissionierung2__2_.jpg)