- Suitable for all pane formats

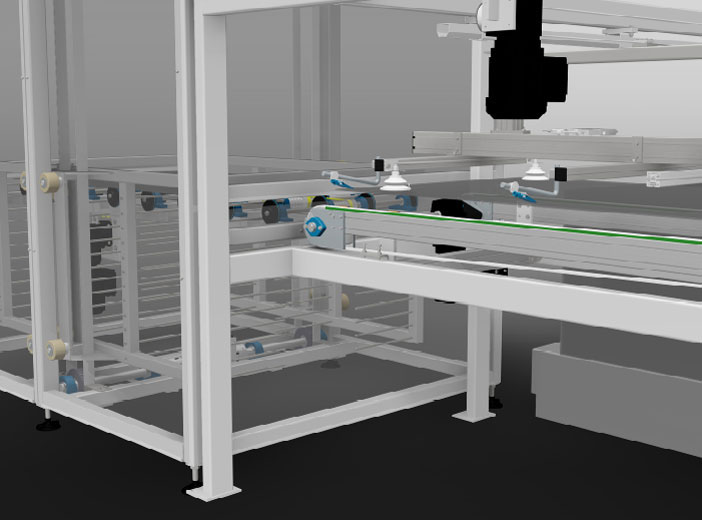

- Operatorless fully automatic process

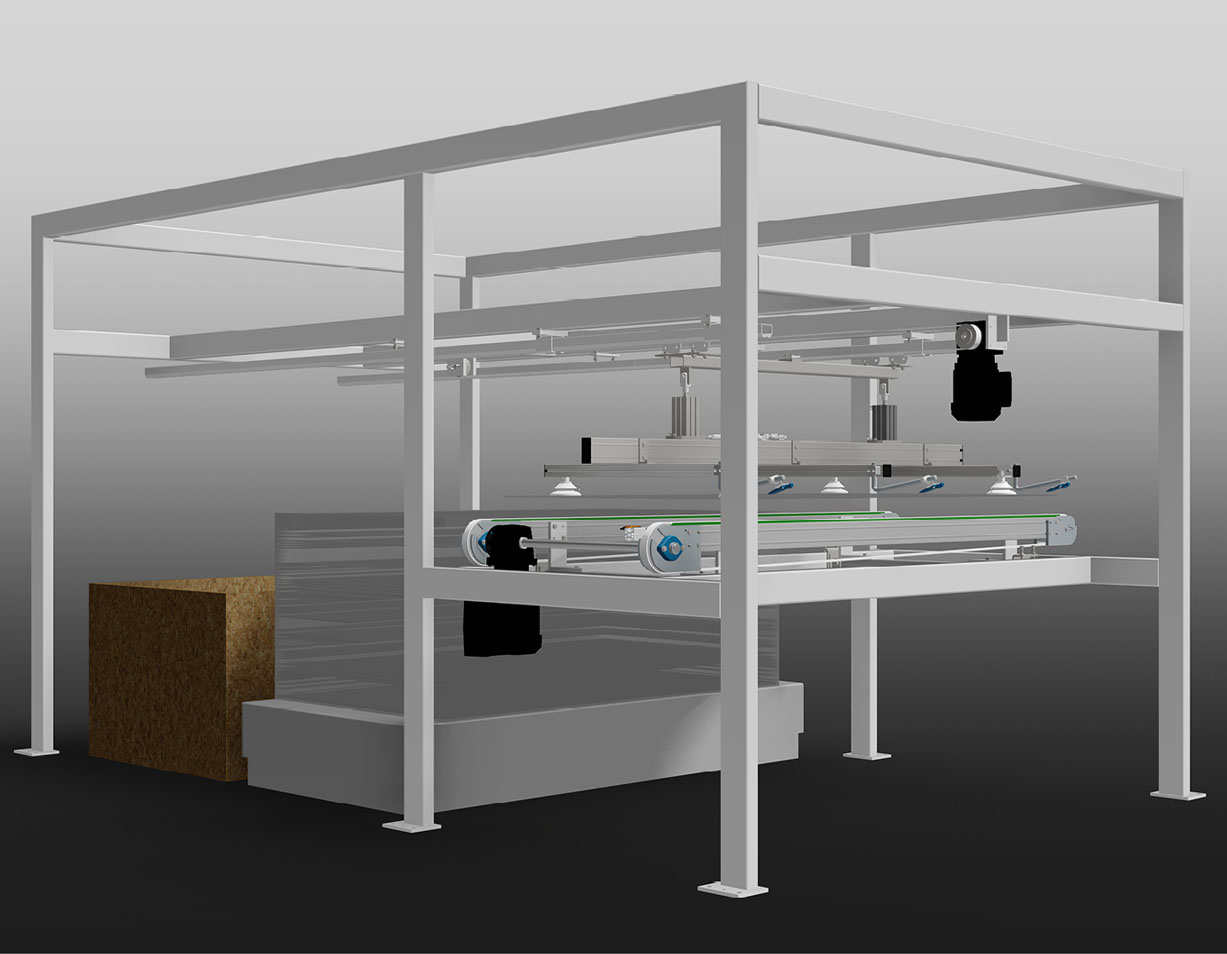

- Simple structure

- Cost-effective, robust design

- Short cycle time for 10-50 MW lines

- Fill level monitoring

Description:

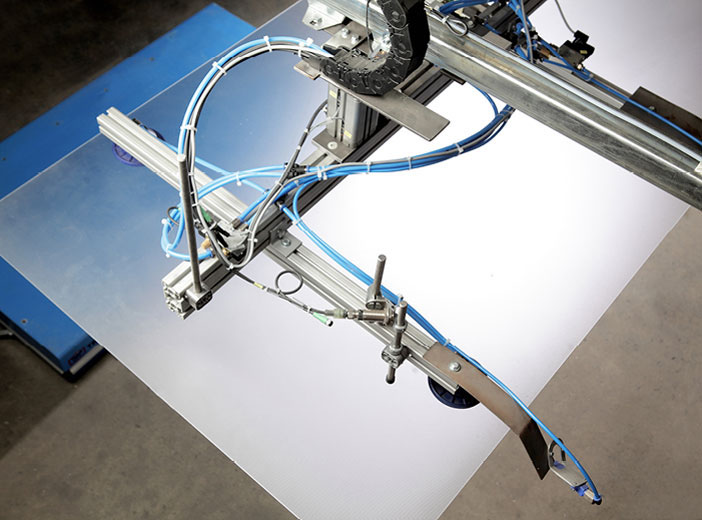

The glass loader lifts the uppermost sheet from the stack, separates the liner and places the sheet on the conveyor. Vacuum suckers pick up the sheet and hold it in place, separating layers are separated from the glass and collected separately. A fill level monitor informs the operator about the necessary pallet change.